PIPER COMANCHE SERVICE MANUAL

04/01/09 II - HANDLING AND SERVICING

1C27

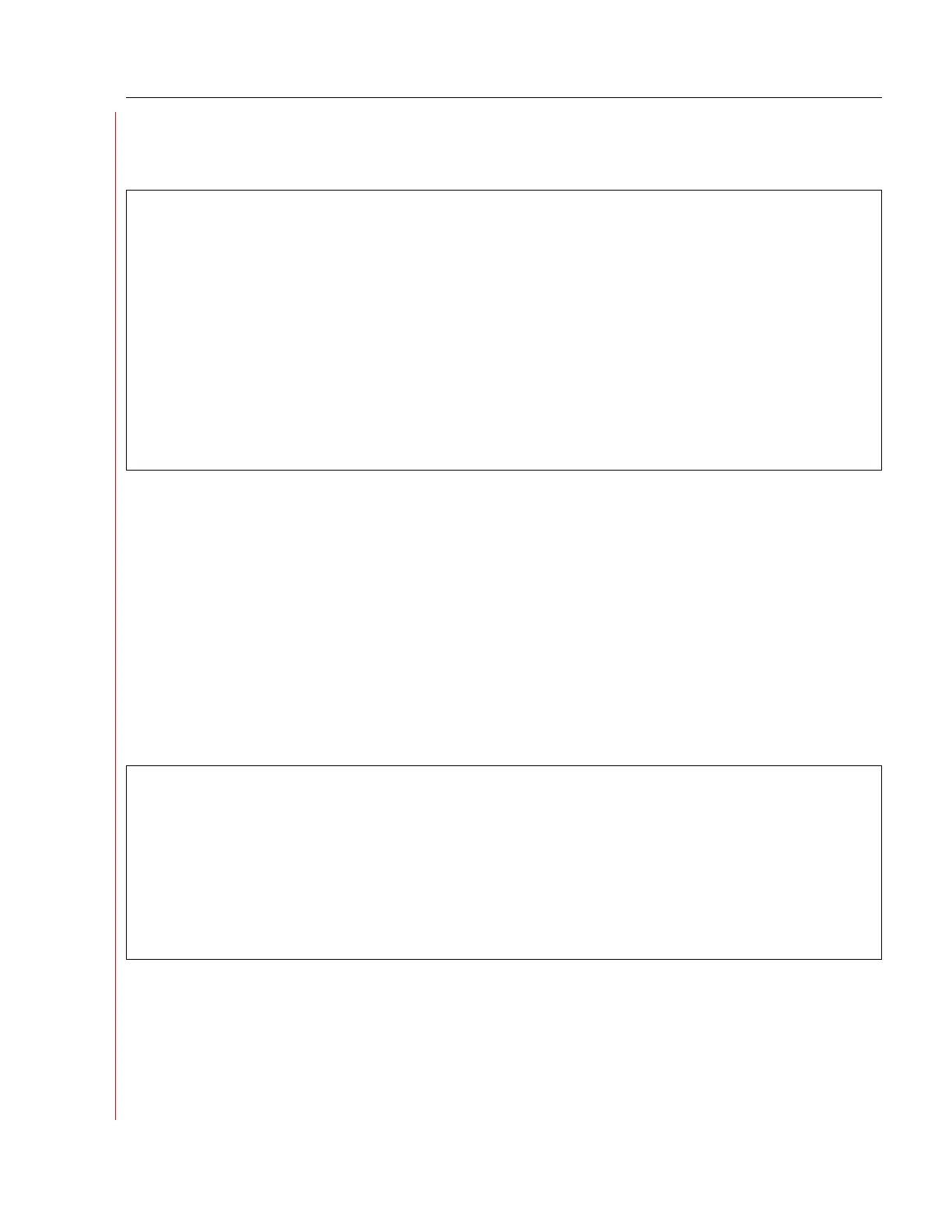

TABLE II-XII. HOSE SPECIFICATIONS

TUBE HOSE HOSE RECOMMENDE MIN MAX MIN

MIL SIZE SIZE SIZE OPER. BURST PROOF BEND

PART NO. O.D. I.D. O.D. PRESS PRESS PRESS RADIUS

MIL-H-8794- 3-L 3/16 1/8 .45 3,000 12,000 6,000 3.00

MIL-H-8794- 4-L 1/16 3/16 .52 3,000 12,000 6,000 3.00

MIL-H-8794- 5-L 5/16 1/4 .58 3,000 10,000 5,000 3.38

MIL-H-8794- 6-L 3/8 5/16 .67 2,000 9,000 4,500 4.00

MIL-H-8794- 8-L 1/2 13/32 .77 2,000 8,000 4,000 4.63

MIL-H-8794-10-L 5/8 1/2 .92 1,750 7,000 3,500 5.50

MIL-H-8794-12-L 3/4 5/8 1.08 1,500 6,000 3,000 6.50

MIL-H-8794-16-L 1 7/8 1.23 800 3,200 1,600 7.38

MIL-H-8794-20-L 1 1/4 1 1/8 1.50 600 2,500 1,250 9.00

MIL-H-8794-24-L 1 1/2 1 3/8 1.75 500 2,000 1,000 11.00

MIL-H-8794-32-L 2 1 13/16 2.22 300 1,400 700 13.25

MIL-H-8794-40-L 2 1/2 2 3/8 2.88 200 1,000 300 24.00

MIL-H-8794-48-L 3 3 3.56 200 800 300 33.00

Construction: Seamless synthetic

rubber inner tube reinforced with one

fiber braid, one braid of high tensile

steel wire and covered with an oil

resistant rubber impregnated fiber

braid.

Identification: Hose is identified by

specification number, size number,

quarter year and year, hose

manufacturer's identification.

Uses: Hose is approved for use in

aircraft hydraulic, pneumatic, coolant,

fuel and oil systems.

Operating Temperatures:

Sizes -3 thru -12: Minus 65°F. to plus

250°F.

Sizes -16 thru -48: Minus 40°F to plus

275°F.

NOTE: Maximum temperatures and

pressures should not be used

simultaneously.

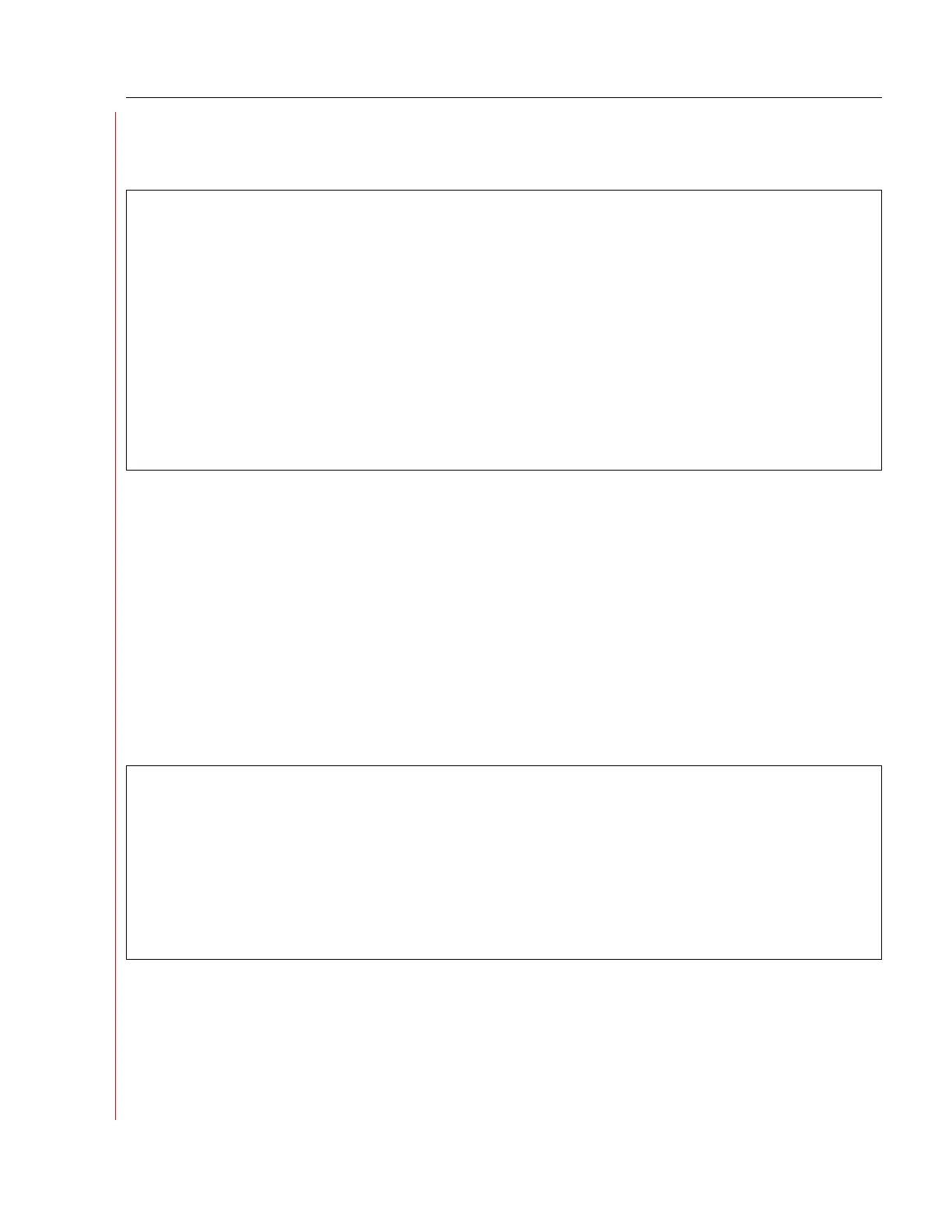

TUBE HOSE HOSE RECOMMEND MIN MAX MIN

MIL SIZE SIZE SIZE OPER. BURST PROOF BEND

PART NO. O.D. I.D. O.D. PRESS PRESS PRESS RADIUS

MIL-H-8788- 4-L 1/4 7/32 .63 3,000 16,000 8,000 3.00

MIL-H-8788- 5-L 5/16 9/32 .70 3,000 14,000 7,000 3.38

MIL-H-8788- 6-L 3/8 11/32 .77 3,000 14,000 7,000 5.00

MIL-H-8788- 8-L 1/2 7/16 .86 3,000 14,000 7,000 5.75

MIL-H-8788-10-L 5/8 9/16 1.03 3,000 12,000 6,000 6.50

MIL-H-8788-12-L 3/4 11/16 1.22 3,000 12,000 6,000 7.75

MIL-H-8788-16-L 1.00 7/8 1.50 3,000 10,000 5,000 9.63

Hose Construction: Seamless synthetic rubber inner tube reinforced with one

fabric braid, two or more steel wire braids, and covered with a synthetic rubber

cover (for gas applications, request perforated cover).

Identification: Hose is identified by specification number, size number, quarter

year and year, hose manufacturer's identification.

Uses: High pressure hydraulic,

pneumatic, coolant, fuel and oil.

Operating Temperature:

Minus 65°F to plus 200°F.

MULTIPLE WIRE BRAID RUBBER COVERED

SINGLE WIRE BRAID FABRIC COVERED

Loading...

Loading...