•

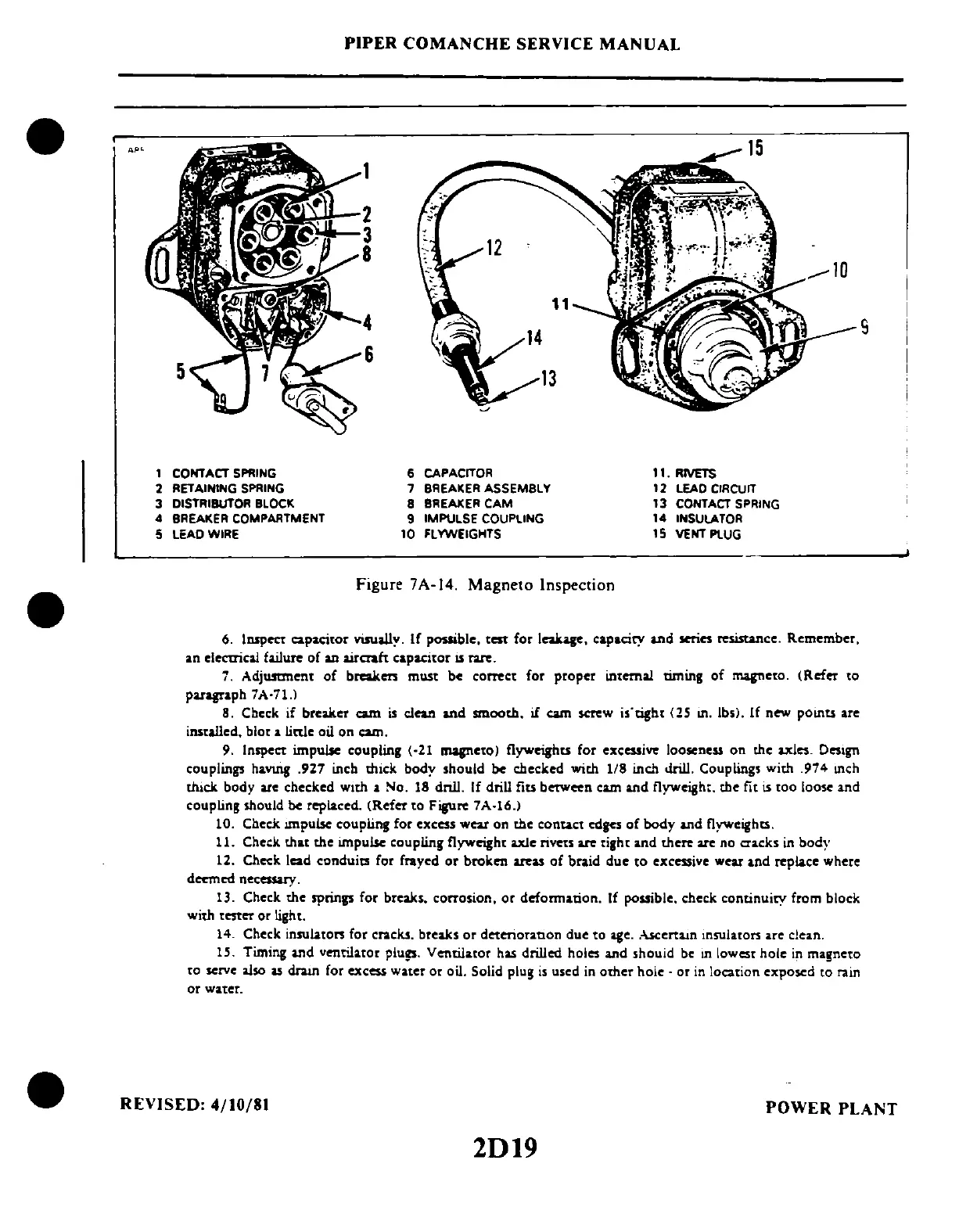

1 CONTACT SPRING

2 RETAINING SPRING

3 DISTRIBUTOR BLOCK

4 BREAKER COMPARTMENT

5 LEAD WIRE

PIPER

COMANCHE

SERVICE

MANUAL

6 CAPACITOR

7 BREAKER ASSEMBLY

8 BREAKER

CAM

9 IMPULSE COUPLING

1 0 FLYWEIGHTS

Figure 7A-14.

Magneto

Inspection

11.

RIVETS

12 LEAD CIRCUIT

13 CONTACT SPRING

14

INSULATOR

15

VENT PLUG

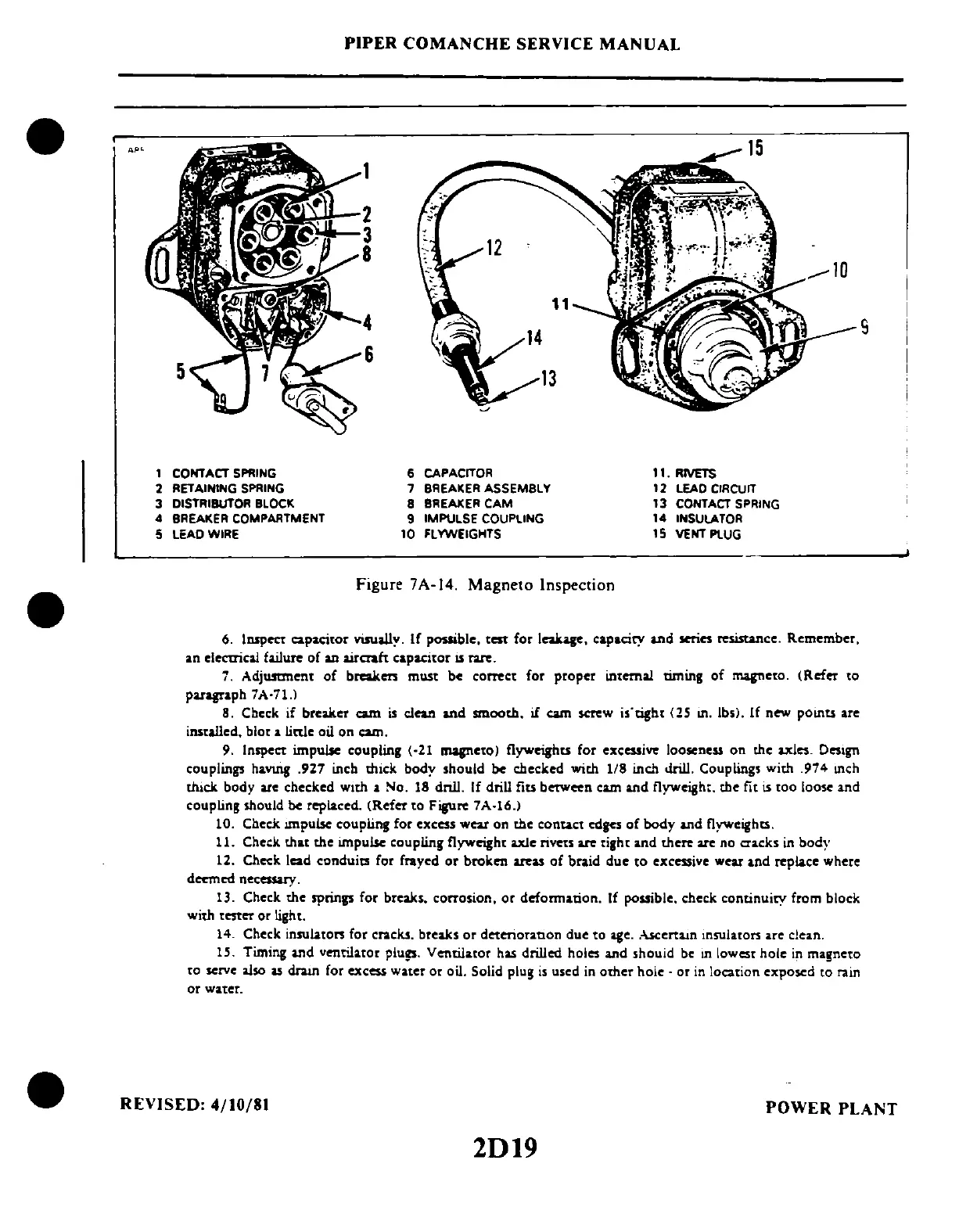

6.

Inspect capacitor visually. If possible. test for leak

....

capaciry and series resistance. Remember.

an

electrical

failure

of

an

airaaft

ca.pacitor

IS

rare.

7. Adjumnent

of

break

...

must be correct for

prop.,

internal timing

of

magneto.

(Ref.,

to

paragraph 7A·71.1

8. Check if breaker cam

is

clean and smooth.

if

cam screw

i'tigh[

(lS

Ill.

Ib,). If new

POIllU

are

installed. blo[

a linle oil on cam.

9.

Inspect impw.e coupling

(·21

mapeto)

flyweighu for excessi

..

loosene

..

on the axles. Design

couplings

havuig

.927 inch thick body should

be

checked with

118

inch drill. Coupling. with .974

Illch

thick body ate checked

With

a No. 18 dnll. If drill

fiu

betWeen cam and flyweight. the fit

is

[00

loose and

coupling should

be

replaced. (Refer

[0

Figure

7A·16.)

10. Check ""pulse coupling for excess wear on the

COntact

edges

of

body and flyweights.

11.

Check

th"

the ""pulse coupling flyweight

uJe

nvo"

....

[igh[ and there

ate

no

cracks

in

body

12. Check lead conduits for frayed or broken areas

of

braid due

to

excessive wear

and

replace where

deemed necessary.

13. Check the springs for breaks. corrosion.

or

defonnation. If possible. check continuiry from block

with

[ester or

Iigh

[.

14.

Check

insulato"

for

cracks.

brca.ks

or

deterioranon

due

to

age

..

-UCcrtaJn

insulators

are

clean.

1

S.

Timing

and

ventilator plugs. Ventilaror has drilled holes

and

shouid

be

In

lowest hole

in

magneto

to serve also

IS

d.ra.tn

for excess water

or

oil. Solid plug

is

used

in

other hoie .

or

in

location exposed to

rain

or

water.

9

REVISED:

4/10/81

POWER

PLANT

2D19

Loading...

Loading...