PIPER COMANCHE SERVICE MANUAL

should be disassembled only so far as is necessary

to make

repair

or

replacement

of

the defective

parts. As a precaution,

wear safety glasses when

disassembling the cranking motor. Following are

general instructions for disassembling a typical

Bendix

dri ve cranking motor:

a.

Remove

the

cover

band,

if

present,

and detach the field coil

leads

from the brush

holders.

b.

If

gear

reduction, remove the drive

housing, and reduction housing.

c. Remove the bolts attaching the drive

housing and commutator end frame to the field

frame assembly. Discard the tang lock washers.

d. Separate the commutator end

fratTI'

armature

assembly,

field

frame,

and

dri .

housing.

BATTERY

AMMETER

CRANKI~NG~~~~~S~TA~L~L~P:::OSITtON

OF

BRAKE

ARM)'

uOTOA'

12'

I

e.

Remove

and

disassemble

the drive

'----------------

___

---'

from the armature shaft by first identifying the type

Bendix drive and then following one

of

the guides

below:

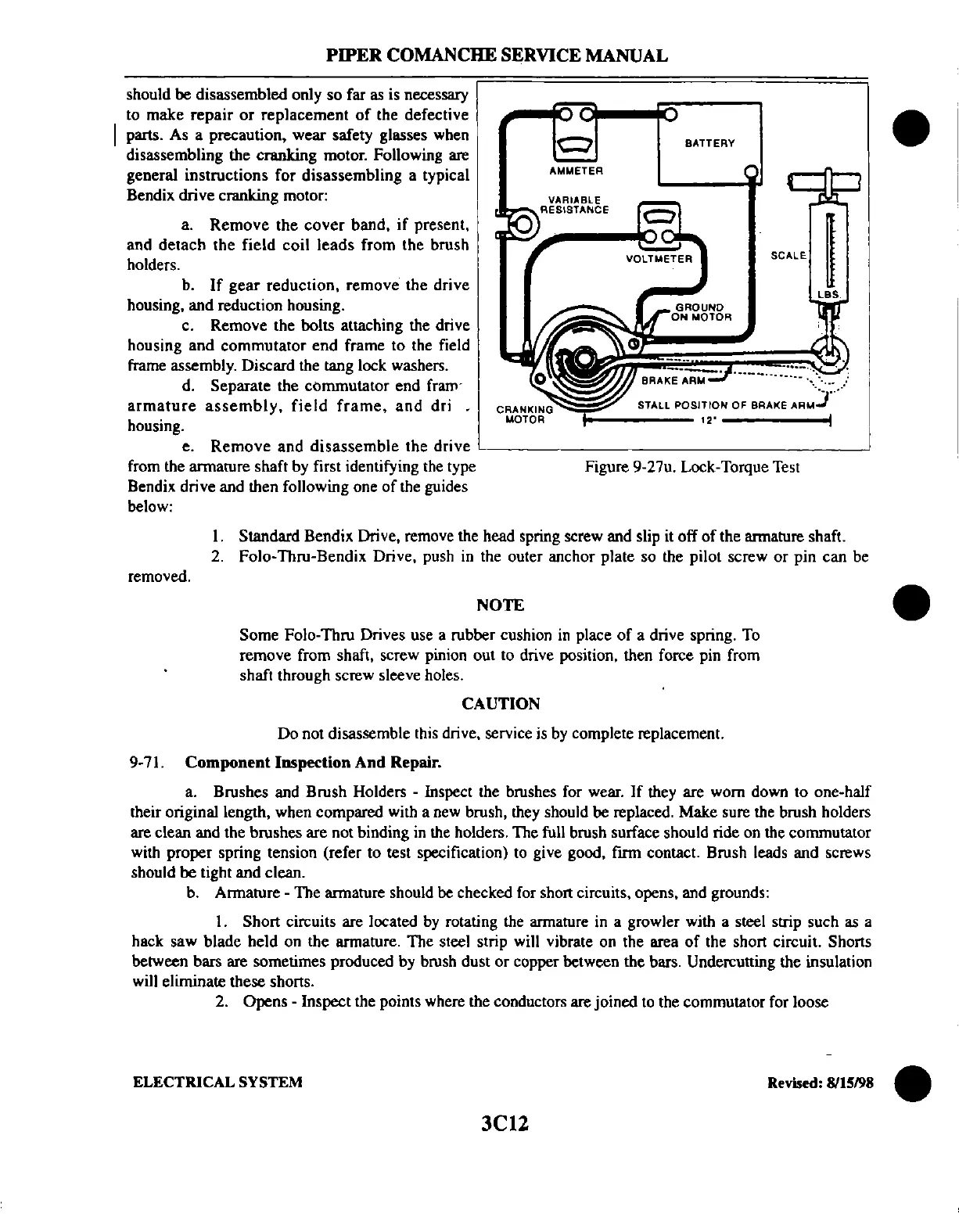

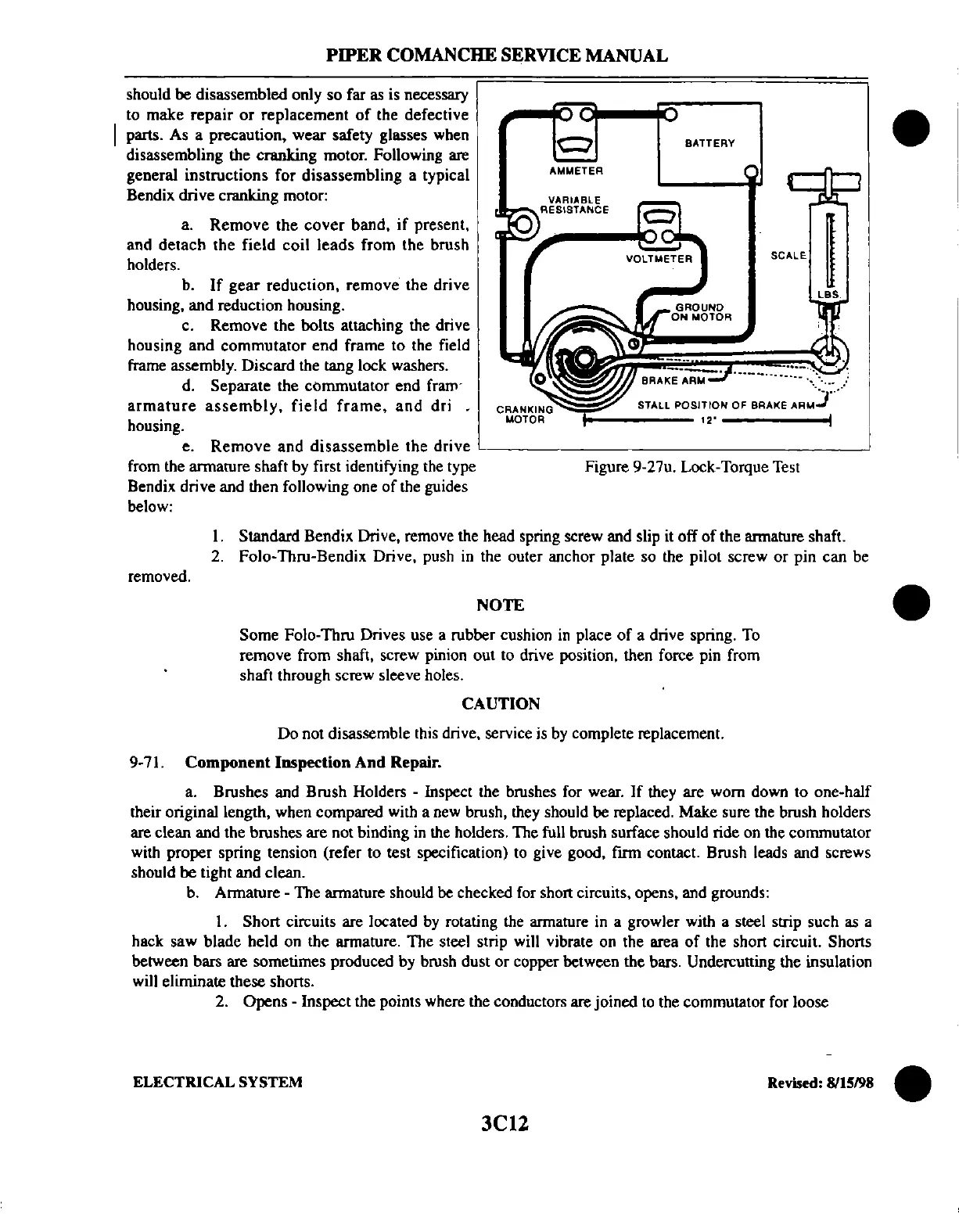

Figure 9-27u. Lock-Torque Test

removed.

I. Standard Bendix Drive, remove the head spring screw and slip it off

of

the armature shaft.

2.

Folo-Thru-Bendix Drive, push

in

the outer anchor plate so the pilot screw

or

pin can be

NOTE

Some Folo-Thru Drives use a rubber cushion

in

place

of

a drive spring.

To

remove from shaft, screw pinion out to drive position, then force pin from

shaft through screw sleeve holes.

CAUTION

Do not disassemble this drive, service is by complete replacement.

9-71.

Component

Inspection

And

Repair.

a. Brushes and Brush Holders - Inspect the brushes for wear.

If

they are worn down to one-half

their original length, when compared with a new brush, they should be replaced. Make sure the brush holders

are clean and the brushes are not binding in the holders. The full brush surface should ride on the commutator

with proper spring tension (refer to test specification) to give good, firm contact. Brush leads and screws

should

be

tight and clean.

b. Armature - The armature should be checked for short circuits, opens, and grounds:

I.

Short circuits are located

by

rotating the armature in a growler with a steel strip such as a

hack saw blade held on the armature. The steel strip will vibrate on the area

of

the short circuit. Shorts

between bars are sometimes produced by brush dust

or

copper between the bars. Undercutting the insulation

will eliminate these shorts.

2.

Opens - Inspect the points where the conductors are joined

to

the commutator for loose

•

ELECTRICAL

SYSTEM

Revised:

8115198

•

3el2

Loading...

Loading...