GTR-3455

Doc Ref: Page: 33

Date: 13/01/13 Issue: H

Pr

seal

®

uk

Tray Sealing Solutions

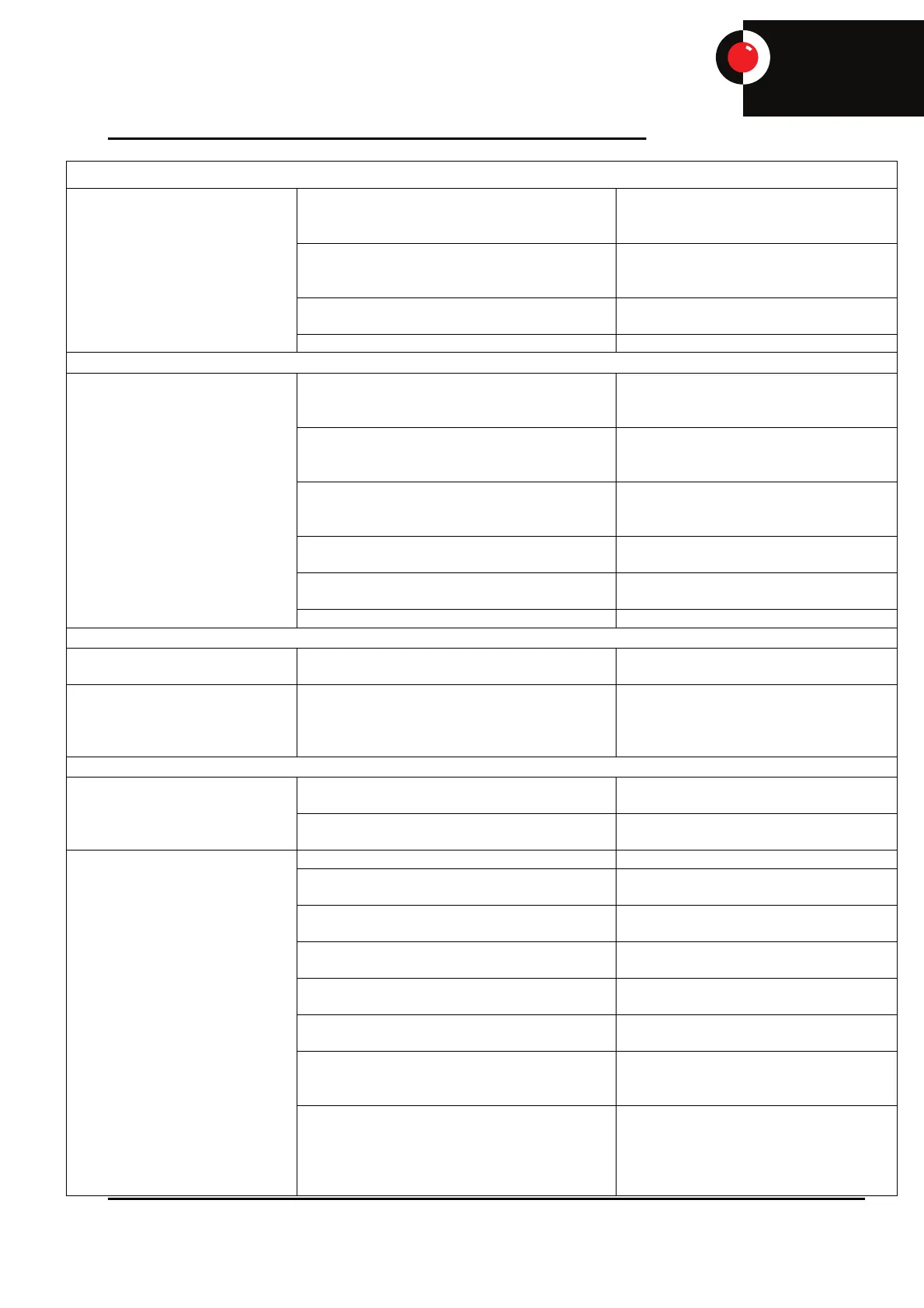

FILM FEED CONT.

Film not feeding correctly

Film path through rollers incorrect

Feed film as per film feed path. If film

printer fitted check film path through

printer

Drive roller rubber coating damaged or

contaminated

Clean drive roller coating with an

alcohol cleaner. Replace if badly

damaged.

Film guides incorrectly positioned

Re-align film guides to suit film roll

being used.

Film feed time incorrect Set time value to suit tooling being run

Noisy during rotation

Drive chain or sprockets damaged or loose

Check condition of film rewind drive

assembly.

Re-tension drive chain or replace.

Worn shaft bearings

Motor bearings worn.

Replace worn bearings and check

condition of shafts.

Check condition of motor.

Drive chain or sprockets damaged or loose

Check condition of film rewind drive

assembly.

Re-tension drive chain or replace

Rewind blade not extended or mechanism

damaged

Push in rewind knob to extend blade

and check spring mechanism

Film guides incorrectly positioned

Re-align film guides to suit film roll

being used.

Film feed time incorrect Set time value to suit tooling being run

Seal head not returning to up

position

Head down switch has not been triggered

Reed switch incorrectly positioned.

Incorrect tooling fitted.

Reposition cylinder reed switch

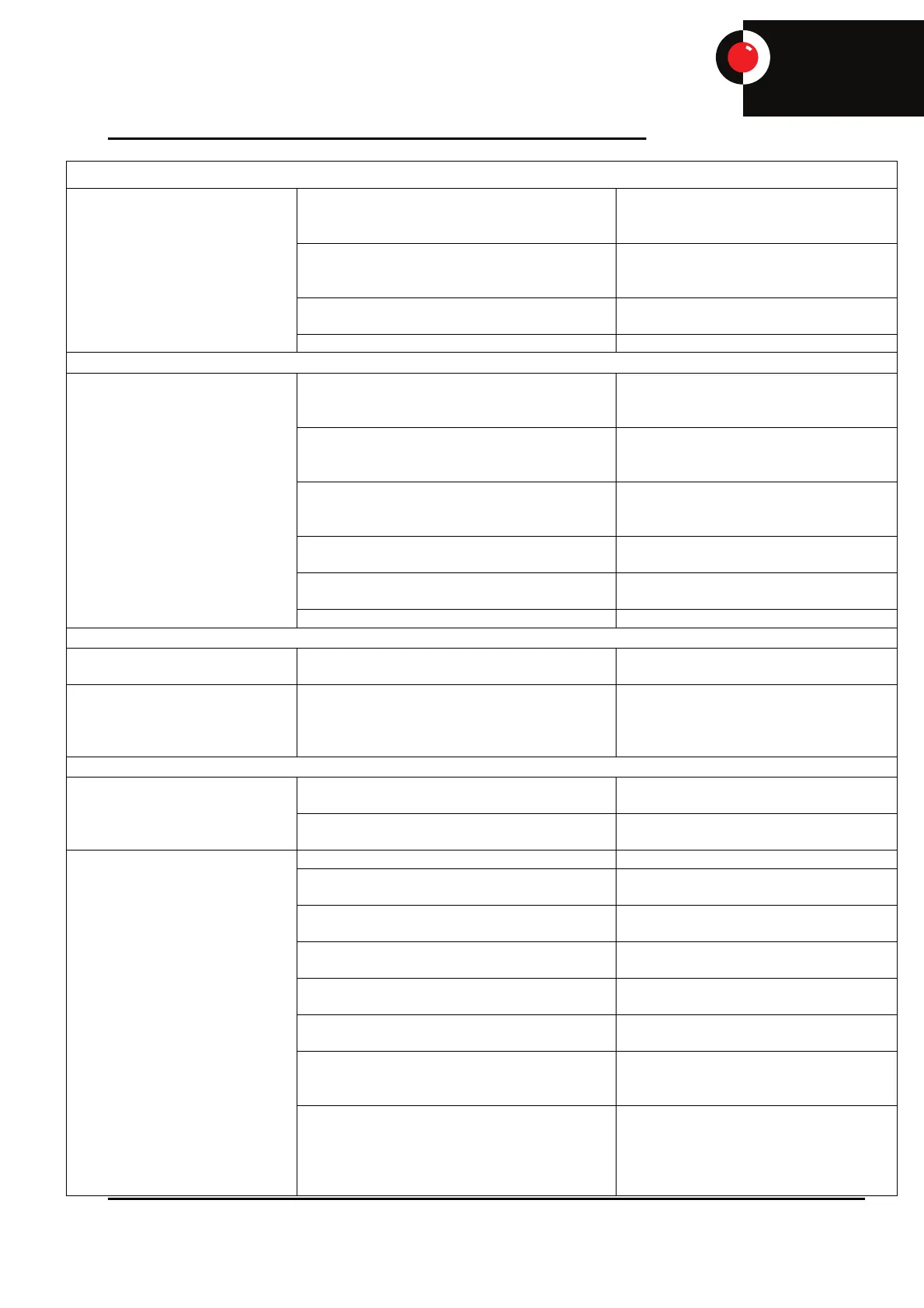

Tool not sealing and cutting

correctly

Cylinder pressure plate positioned

incorrectly.

Seal cylinder lock nut loose.

Re-adjust cylinder pressure plate to

the correct position. Consult Proseal

for advice.

Trays do not sit in base tool

correctly

Tray supplier has changed

Check tray is correct for tooling if in

doubt consult Proseal.

Tray depth too deep for tool eject

If tray has to be used in production

remove eject pads. Consult Proseal

Weak seal

Tool has not reached set temperature. Allow tool to reach set temperature.

Set temperature too low

Increase temperature value until

require seal is achieved.

Seal time value is too low.

Increase seal time until require seal is

achieved.

Faulty heater element

Check condition of heater and replace

if damaged.

Faulty Thermocouple

Check condition of thermocouple and

replace if damaged.

Low air pressure

Check air pressure and adjust to

required value.

Tray and film materials incompatible or

defective batch supply.

Check suitability with tray and film

supplier.

Consult Proseal for advice.

Tool contaminated

Inspect profile for contamination and

clean if required.

Loading...

Loading...