GTR-3455

Doc Ref: Page: 34

Date: 13/01/13 Issue: H

Pr

seal

®

uk

Tray Sealing Solutions

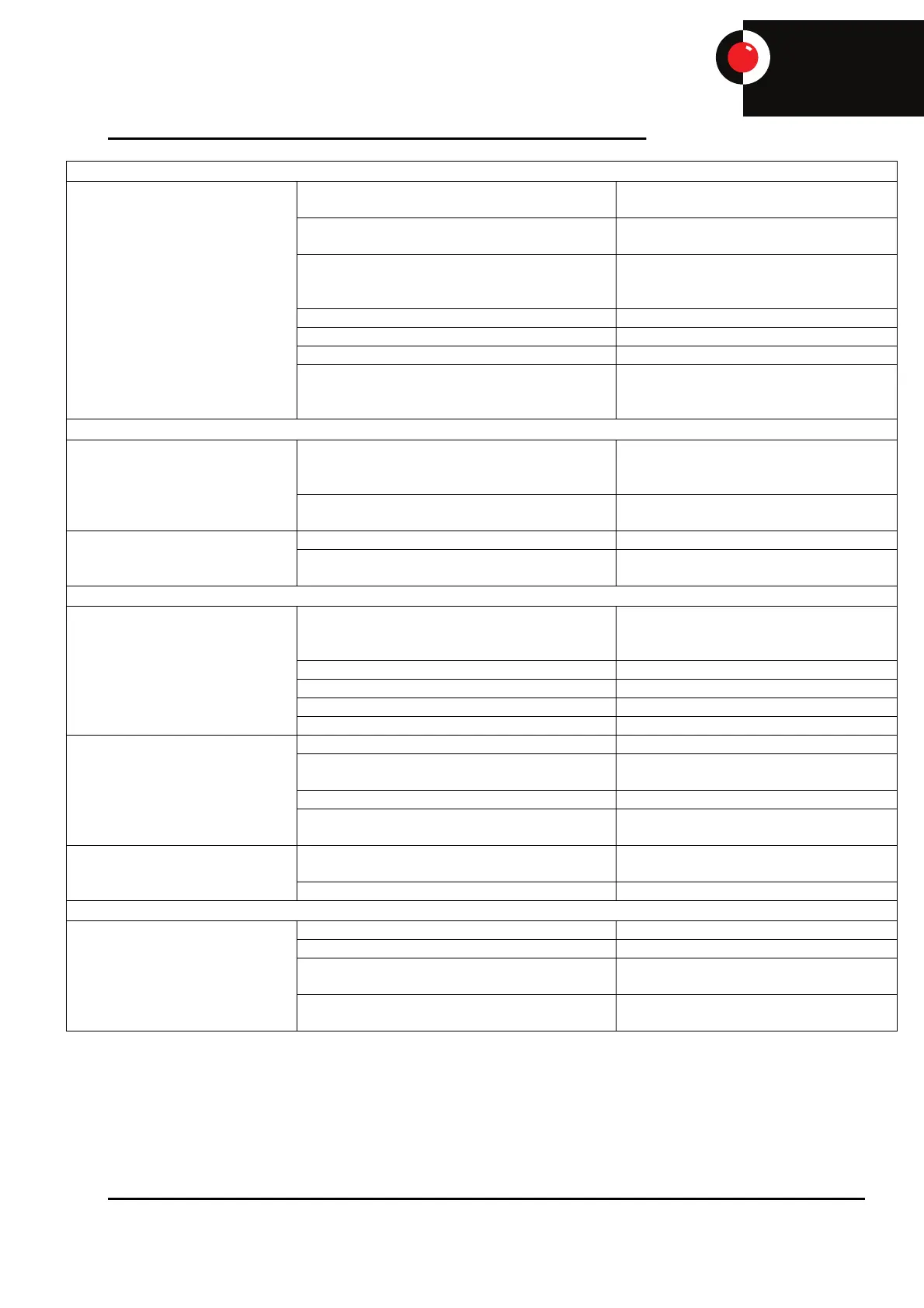

Inconsistent seal quality

Excessive draughts around the top tool

Move machine to a draught free

location

Faulty heater element

Check condition of heater and replace

if damaged.

Uneven seal profile face

Check profile for flatness. Seal profile

can be skimmed flat if not too badly

damaged

Contamination on seal profiles Clean seal profiles carefully

Seal rubber damaged or missing Replace seal rubber

Seal spring misplaced or broken Reseat or replace damaged springs

Lidding film wrinkled

Check film rewind tension is set

correctly and film is positioned

correctly on top tool film spreader.

Tray sticking in base tool

during eject

Seal temperature or time too high causing

tray flange to distort

Reduce seal temperature and time

Thermocouple incorrectly located or

damaged

Tray or film supplier has changed

Check tray and film are suitable for

tooling being used

Tray flange being cut by

trimblade

Base and top tool misaligned Check tooling alignment on machine.

Trimblade contaminated; damaged or

distorted

Clean or replace trimblade

Film snapping during film feed

cycle

Film feed time too short

Increase film feed time to ensure film

is fed enough to clear last tool

impression

Film path incorrect through machine Check film path is correct

Film width too short Use correct film width

Film rewind tension too high Reduce tension to a suitable level

Seal profiles contaminated Clean seal profiles

Uneven film cut around tray

perimeter

Clamp rubber damaged or missing Replace clamp rubber

Trimblade contaminated; damaged or

distorted

Clean or replace trimblade

Low air pressure Check regulator and air supply

Tool heights incorrect

Check base tool to top tool

relationship.

Pack ballooned after sealing

Base tool knife slot vent holes blocked

Clean knife slots or add additional

vent holes

Too much gas in pack after sealing Reduce gas flush pressure or time

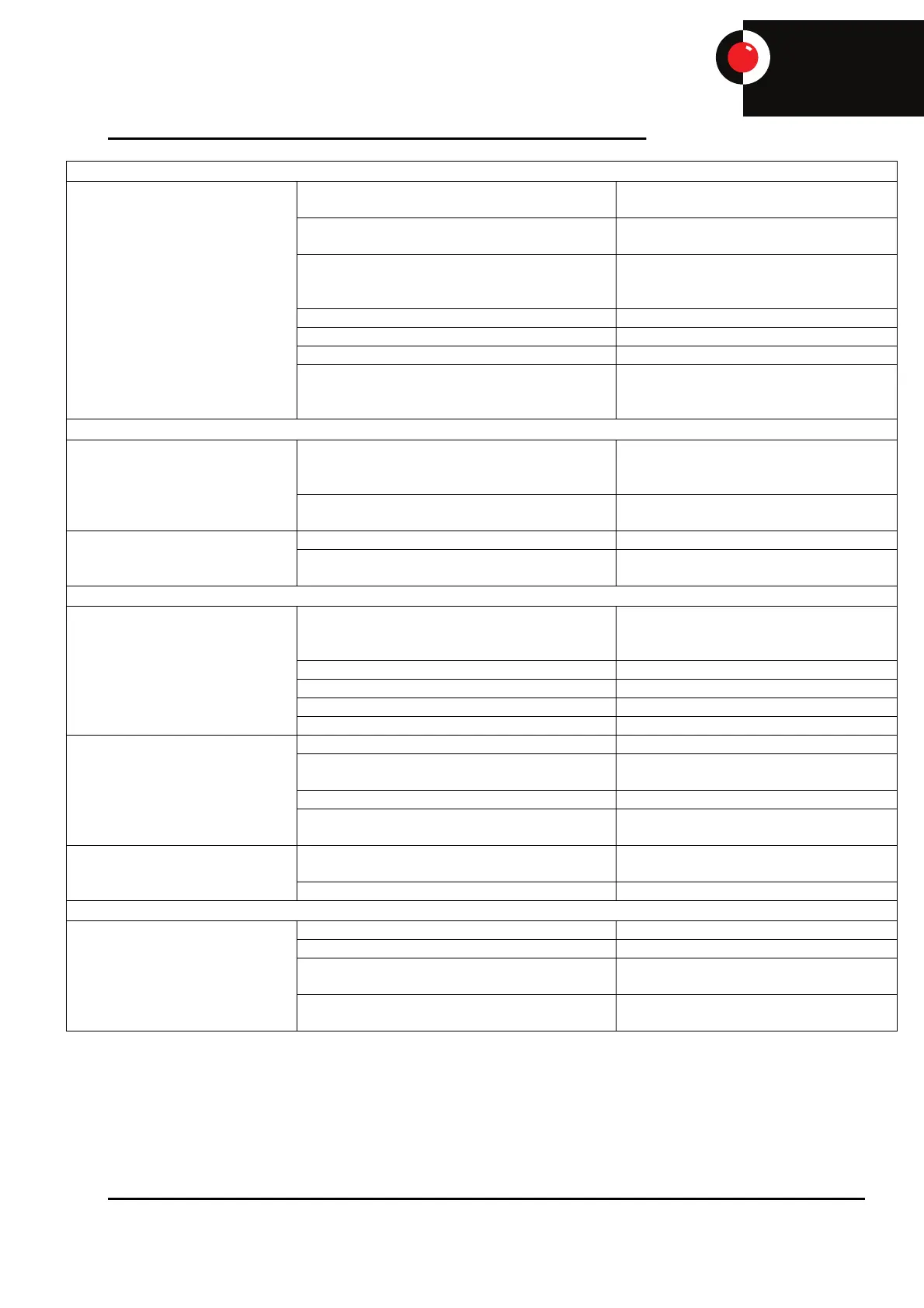

GAS FLUSHING/VACUUM ISSUES

Poor gas content

Gas flush time set too low Adjust gas flush time

Gas pressure set too low Adjust gas pressure

Incorrect type of modified atmosphere

packaging gas being used

Check flushing gas is correct for

product

Leak on the gas flushing or vacuum circuit.

Check gas flush or vacuum circuit for

leaks

Loading...

Loading...