GTR-3455

Doc Ref: Page: 32

Date: 13/01/13 Issue: H

Pr

seal

®

uk

Tray Sealing Solutions

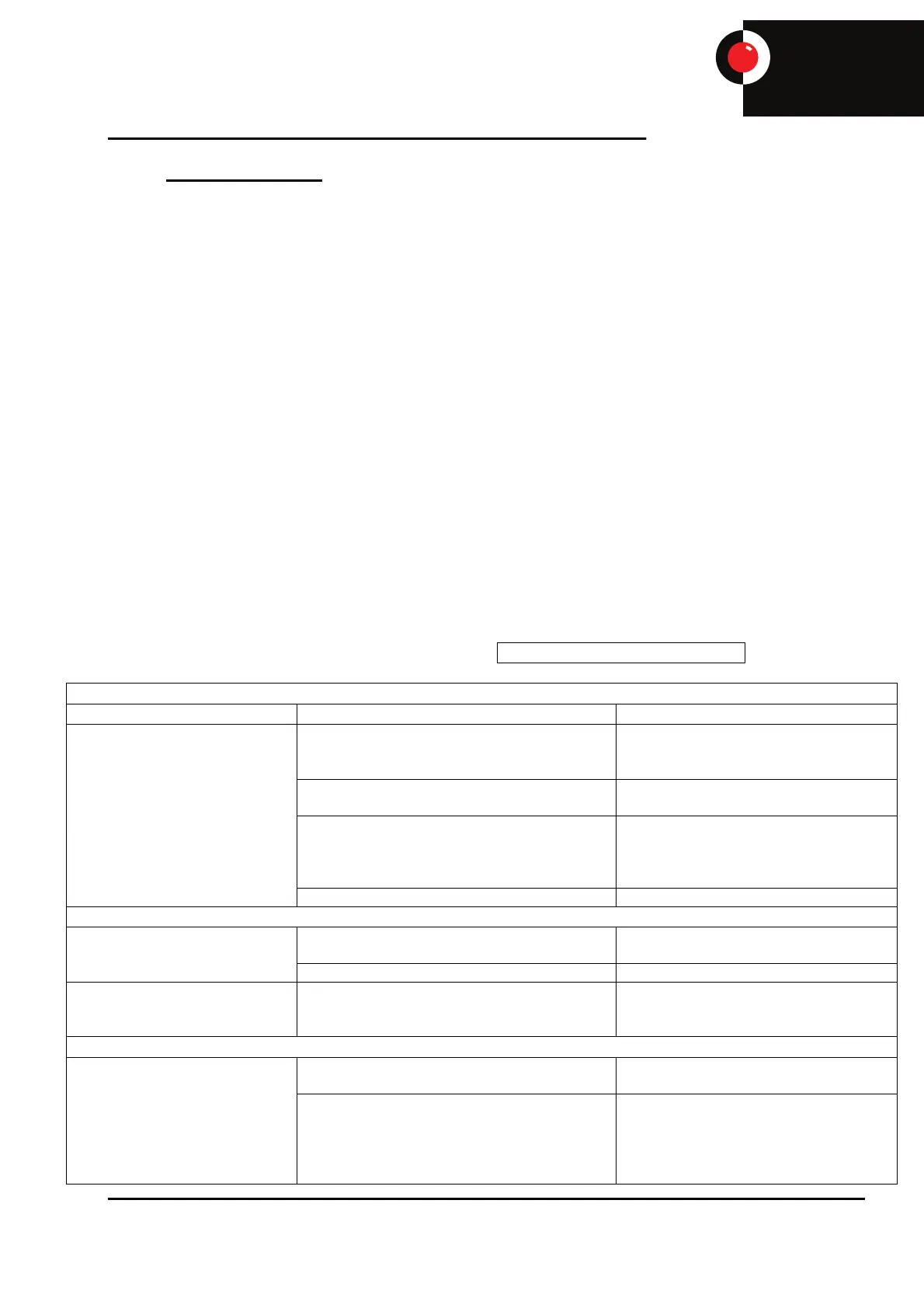

5. FAULT DIAGNOSIS

There are various methods of assisting with the machine fault diagnosis, but the most productive

results come from the logical approach, coupled with a good understanding of the machine.

We recommend that, although this section outlines some common product fault conditions you may

encounter on your machine, it is more important that you understand the principles of operation and

control sequences. The table below details some potential faults which may occur during the

operation of the machine. If a fault occurs which you are unable to diagnosis contact Proseal.

If you have a fault condition:

ELIMINATE THE "OBVIOUS" - e.g. Low air pressure, power failure, guard’s open or emergency

stop button depressed. Always ensure that all sensors are correctly positioned and aligned.

CONSULT YOUR MACHINE'S DOCUMENTATION - Study the available drawings, control

circuits, control programs, etc.

Unless you have a clear understanding of the design of the machine you are unlikely to RECTIFY

FAULTS (although you may succeed in temporarily curing the SYMPTOM).

Variations in the lidding and tray material quality may cause sealing problems on the machine,

endeavour to eliminate these before attempting heat adjustment.

If, however, you are unable to resolve any problems do not hesitate to contact us. We are always

available (24/7) with expert advice and assistance. Telephone Proseal 01625 8566

Noisy or difficult to turn during

rotation

Worn bearings

Check bearing condition. Replace if

required.

Machine table contaminated with product or

packaging

Clean area around machine table and

bearings

Table catching on tooling or guarding

Check guards are fitted correctly.

Check the top tool is secure.

Check the tool is correct for the

machine type

Table damper adjusted incorrectly Check damper adjustment.

Machine noisy during

operations.

Check silencers are fitted and in good

condition.

Replace damaged or missing

silencers

Pneumatic fittings leaking Refit or replace leaking fittings

Seal and eject cylinder slow to

actuate

Low air supply to machine.

Incorrect regulator setting.

Leaking fittings or control devices

Check air supply to machine and

regulator setting. Refit or replace

leaking fittings

Noisy during rotation

Worn roller bearings

Replace worn bearings and check

condition of shafts.

Drive belts incorrectly adjusted.

Motor bearings worn.

Drive pulleys loose or worn

Rollers running against machine sideplates

Tension drive belts correctly.

Check condition of motor.

Remount pulleys or replace.

Reposition film feed rollers and check

bearings.

Loading...

Loading...