5

Manual No. 016-0171-362 Rev. F 41

ISOBUS PRODUCT CONTROL OPERATION

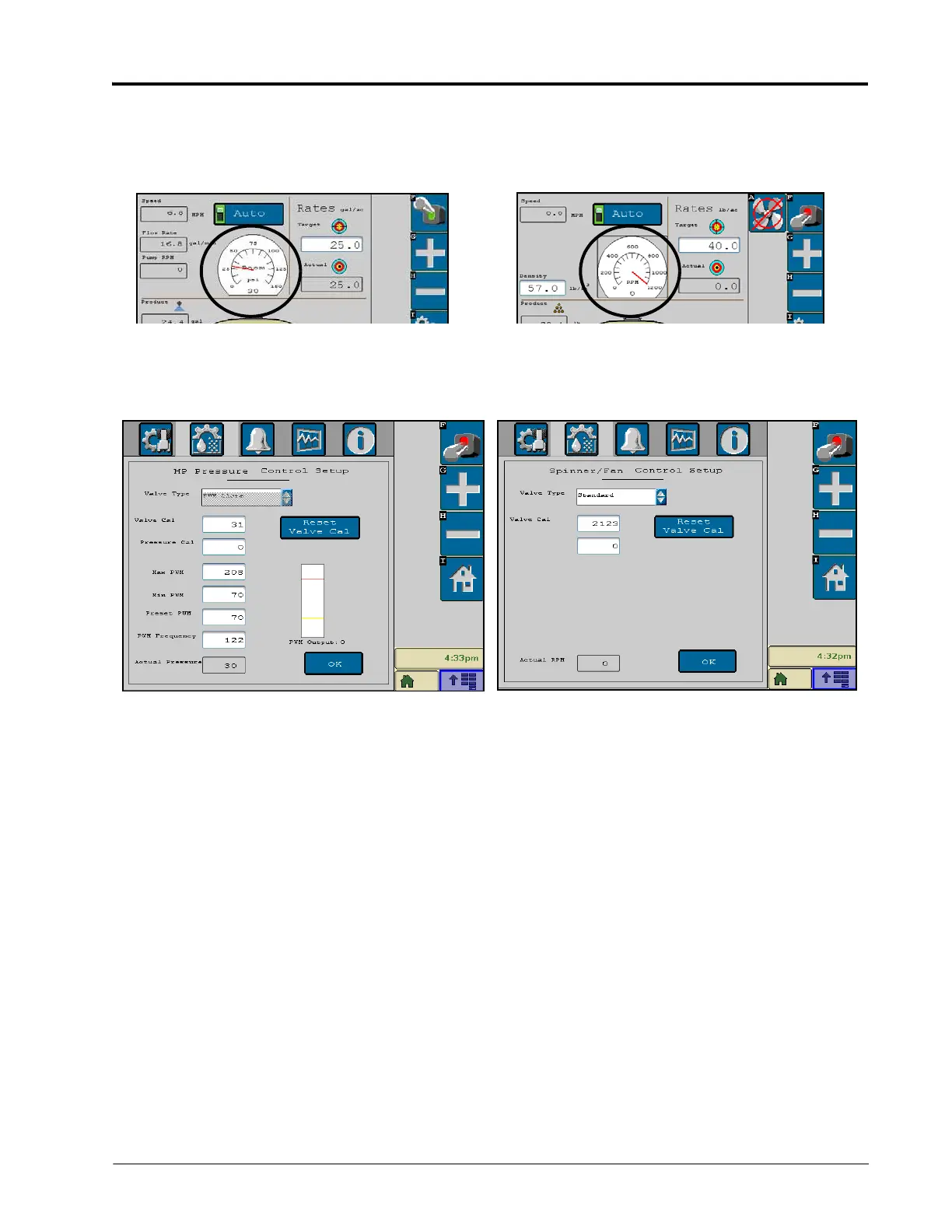

PRESSURE OR SPINNER/FAN RPM DISPLAY

A pressure (liquid and NH3 applications) or RPM (granular applications) gauge is displayed in the upper, center of

the product control home screen.

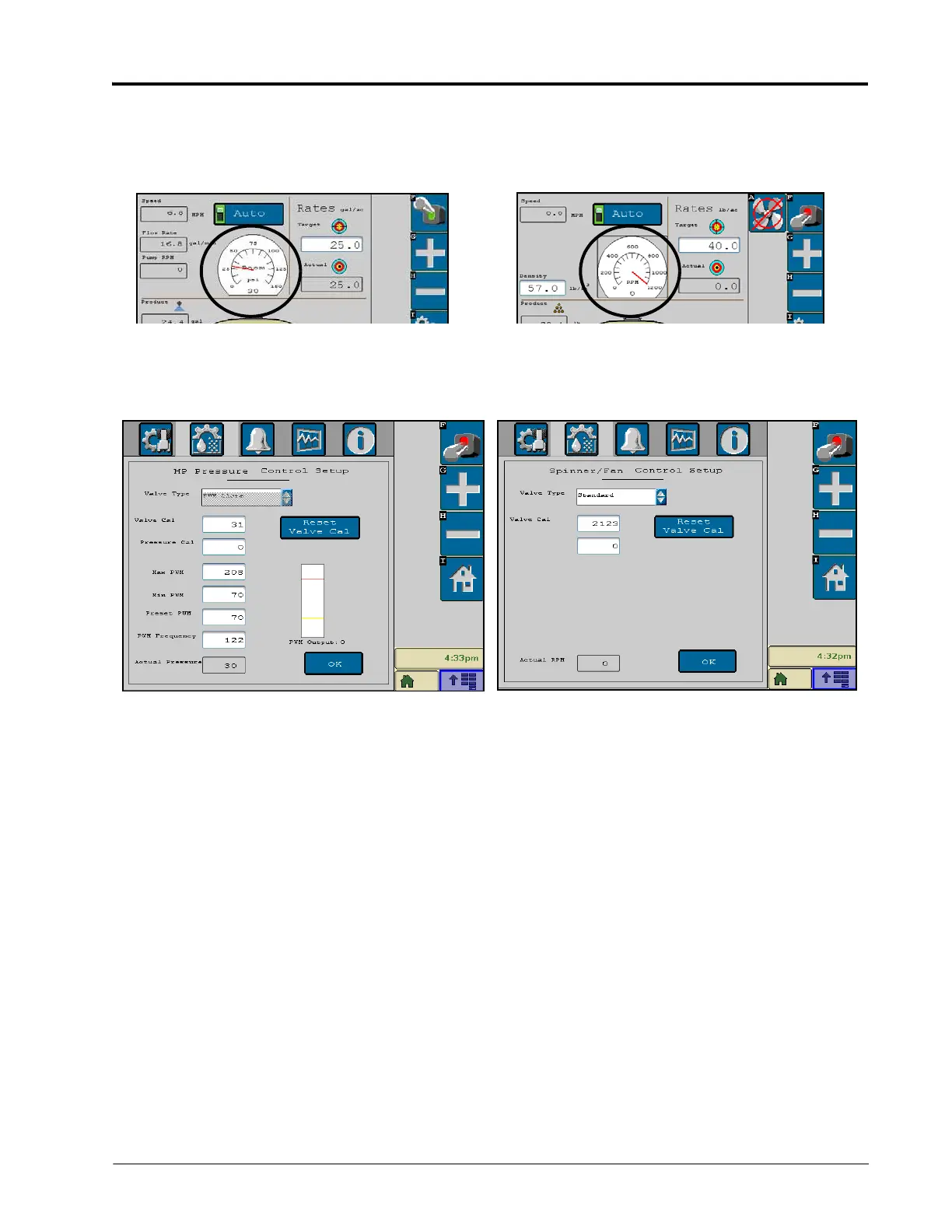

HP PRESSURE OR SPINNER/FAN CONTROL

If the control type selection is set to “Spreader - Spinner” or “NH3 Applicator,” select the gauge displayed on the

product control home screen to view either the HP Pressure or Spinner/Fan Control screen.

Control Mode (Auto/Manual). The control mode indicator displays the selected mode for pressure or RPM

control. Select the “Auto/Manual” button to toggle the application mode between automatic and manual. The

active mode displays green in the display.

• Manual mode allows the operator to control the actual pressure or RPM manually. Select the increase or

decrease buttons while viewing the HP Pressure Control or Spinner/Fan Control screen to manually increase or

decrease the pressure or spinner/fan RPM.

• In Automatic mode, the product control system automatically adjusts the application rate to an operator set

target rate. The increase and decrease buttons will have no affect on the pressure or RPM values in automatic

mode. Refer to the Target Pressure or RPM section below to change the target pressure or RPM in automatic

mode.

Target Pressure or RPM. Select the target pressure or RPM field and use the on-screen keypad to set a target

pressure for the AccuFlow HP boost pump or a target RPM for the spinner or fan.

Enter the desired target pressure to maintain in the anhydrous ammonia application lines. The pressure cal may be

set between 0 and 250 PSI [0 and 1724 kPa].

NOTE: For best results, set the boost pump target rate 5 to 10 PSI [34 to 68 kPa] above the static tank

pressure. If the boost pump pressure is set too high, excess vapor will form in the supply lines. If vapor

builds up in the supply lines, the boost pump may become vapor locked which results in no pressure

boost.

Loading...

Loading...