APPENDIX

C

Manual No. 016-0171-362 Rev. F 71

APPENDIX C

FLOW METER MAINTENANCE

AND ADJUSTMENT

PROCEDURE

FLOW METER MAINTENANCE

NOTE: Thoroughly bleed nurse tank hose and all other system lines prior to disassembling the flow meter,

fittings, or hoses.

1. Remove flow meter from the vehicle and flush with clean water to remove any chemicals.

2. Remove flange bolts or clamp from the flow meter.

3. Remove the turbine hub and turbine from inside flow meter.

4. Clean turbine and turbine hub of metal filings or any other foreign material, such as wettable powders. Confirm

that the turbine blades are not worn. While holding the turbine hub in your hand, spin turbine. The turbine

should spin freely with very little drag inside the hub.

5. If transducer assembly is replaced or if turbine stud is adjusted or replaced, verify the turbine fit before

reassembling. Hold turbine hub with turbine on transducer. Spin turbine by blowing on it. Tighten turbine stud

until turbine stalls. Loosen turbine stud 1/3 turn. The turbine should spin freely.

6. Re-assemble flow meter.

7. Using a low pressure (5 psi) [34.5 kPa] jet of air, verify the turbine spins freely. If there is drag, loosen hex stud

on the bottom of turbine hub 1/16 turn until the turbine spins freely.

8. If the turbine spins freely and cables have been checked per Testing Flow Meter Cables section on page 71, but

flow meter still is not metering properly, replace flow meter transducer.

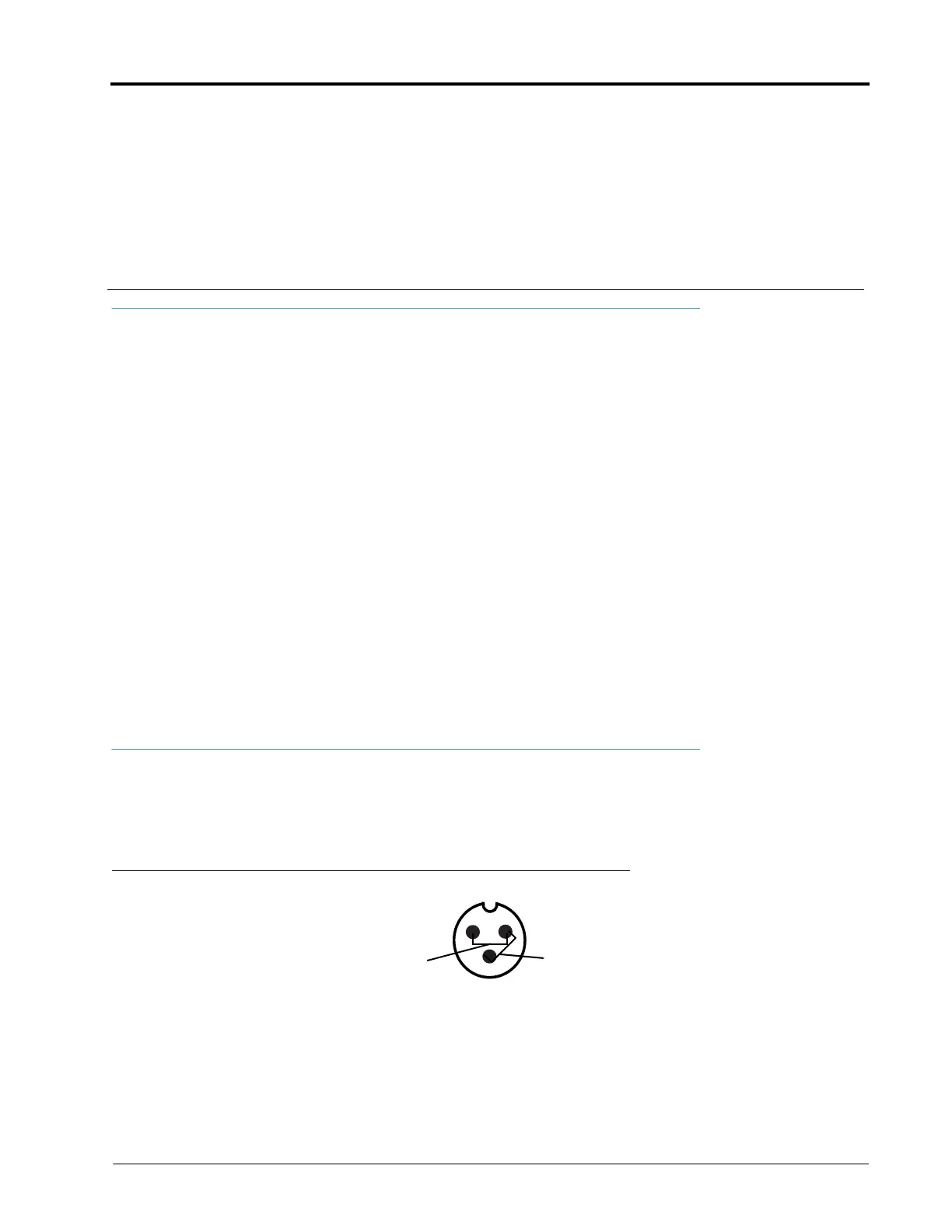

TESTING FLOW METER CABLES

Disconnect the extension cable from the flow meter. Hold the flow meter cable so that the keyway is pointing in

the 12 o’clock position.

FIGURE 1. Flow Meter Extension Cable Pin Diagram

TESTING THE FLOW METER/ENCODER CABLE

1. From the main Raven ISOBUS control screen, select the tools icon from the softkeys area to access the ISOBUS

control node configuration screens.

Loading...

Loading...