CHAPTER

6

Manual No. 016-0171-362 Rev. F 47

CHAPTER 6

TROUBLESHOOTING

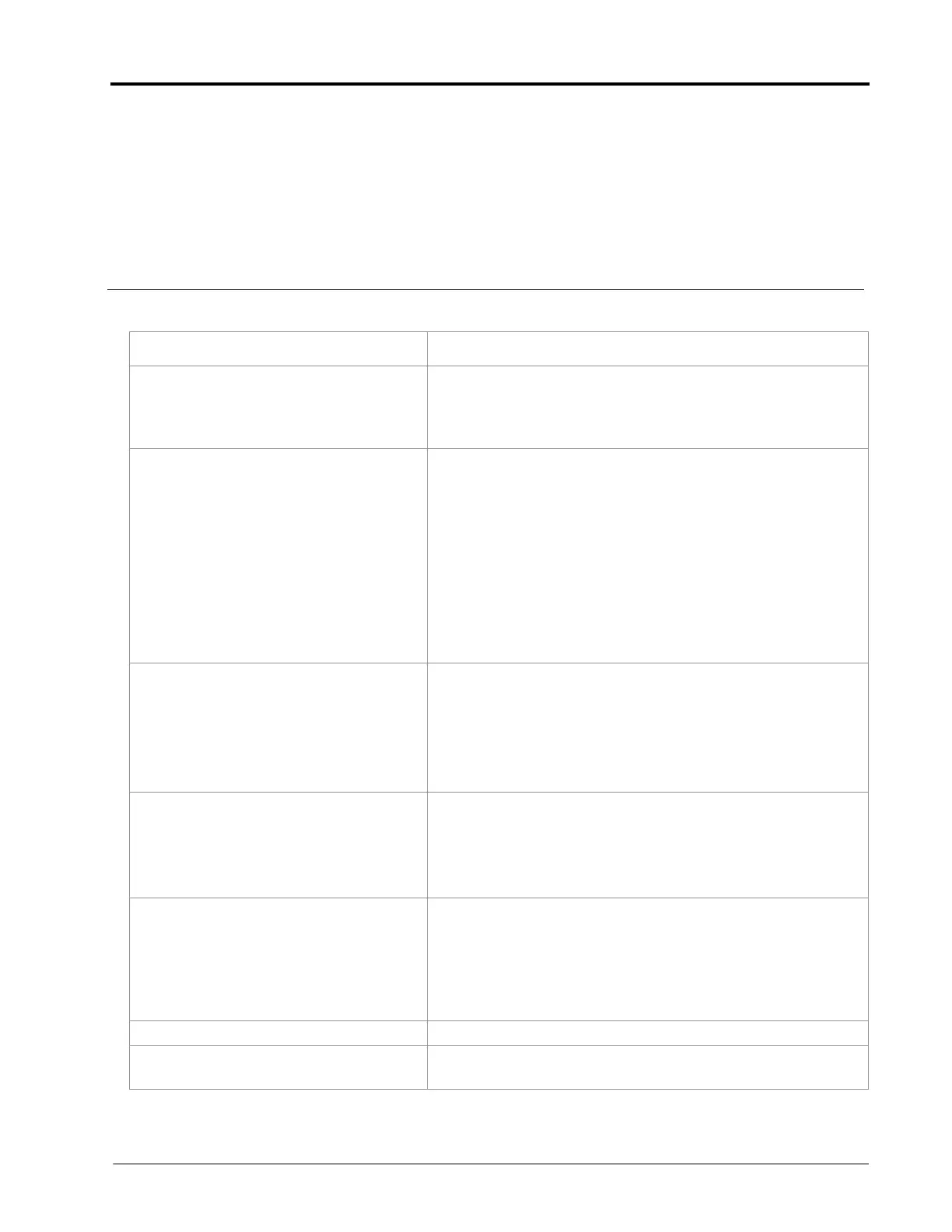

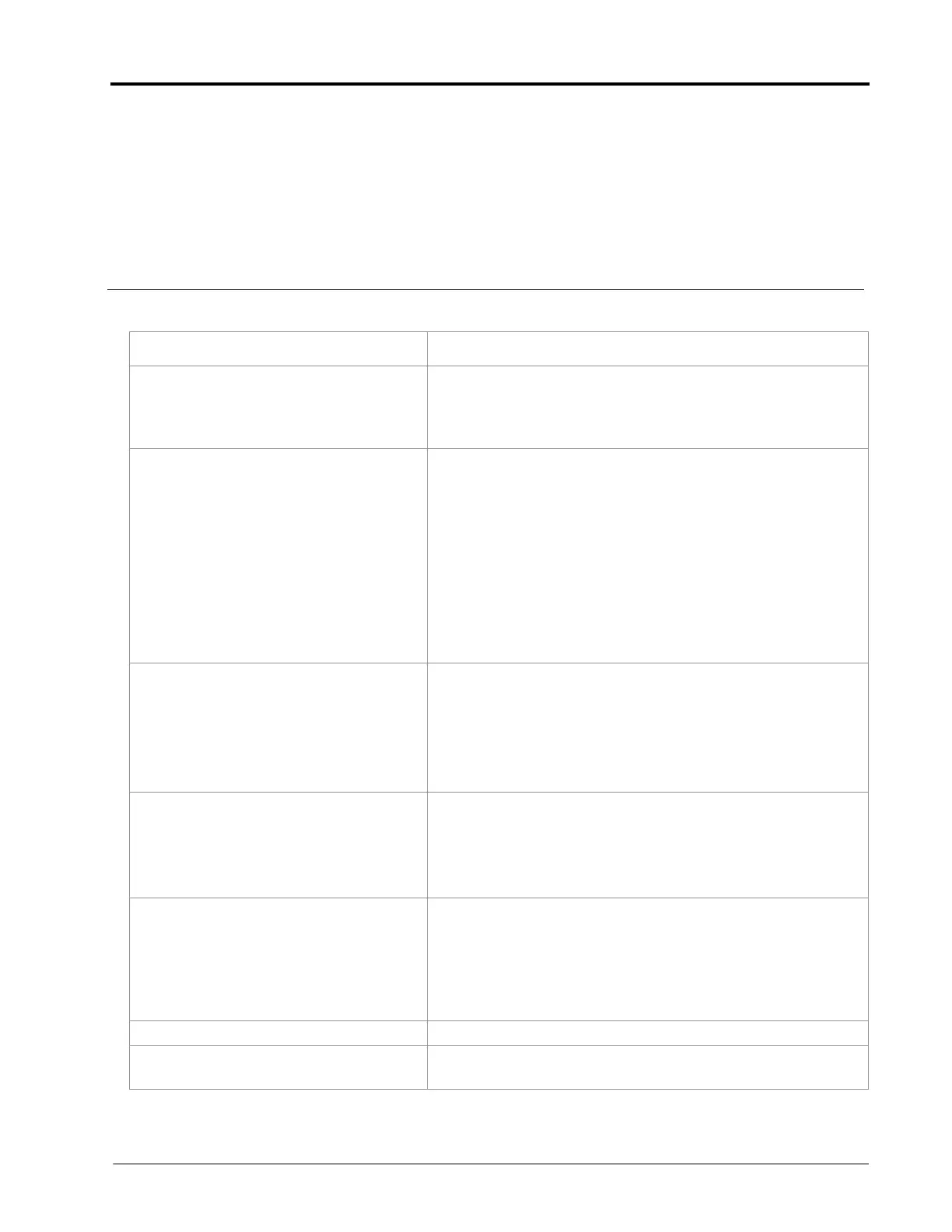

Problem Action

1. Rate reads “0.” • Verify SPEED is registering accurately. If SPEED is zero, refer to

the VT display troubleshooting procedure.

• Verify TOTAL VOLUME is registering flow. If not, refer to

problem 6.

2. Rate inaccurate or unstable. • Verify that all calibration numbers and settings keyed into the

console are correct. Verify SPEED is registering accurately. If

SPEED is inaccurate, refer to the VT display troubleshooting

procedure.

• In MAN (manual) operation, verify that RATE display holds

constant. If not, refer to problem 7.

• Confirm that boom section status shown on the display is not

changing.

• In MAN (manual) operation, check low end and high end

pressure range. If pressure cannot be adjusted manually, refer to

problem 6.

3. Cannot verify rate in manual operation

or in auto.

• Check cabling to motorized control valve for breaks.

• Check connections in cabling for cleanliness.

• Verify that there is voltage at the valve connector by toggling

master switch ON; AUTO/MAN switch to MAN; and POWER ON.

Manually operate INC/DEC switch to verify voltage.

• Verify that valve is turning, if not, replace control valve.

4. Sprayer pressure is correct but RATE is

low.

• Verify that nozzle strainer screens or check valves are not

plugged.

• Verify that pressure at each boom is the same.

• Verify all nozzles are of proper and same orifice size. See

Appendix 8, Calculating the Calibration Values.

5. Total volume does not register. • Check flow meter/encoder cable for breaks and shorts. See the

Testing the Flow Meter/Encoder Cable section on page 71.

• Check the internal components of the flow meter/encoder;

clean and adjust. Appendix C, Flow Meter Maintenance and

Adjustment Procedure for flow meter cleaning and adjustments.

• Replace flow meter transducer/encoder.

6. Total volume registers flow inaccurately. • Verify that arrow on flow meter is pointing in direction of flow.

7. Motorized control valve rotates more

than 1/4 turn.

• Replace motorized control valve.

Loading...

Loading...