CHAPTER 6

48 ISOBUS Product Control Installation & Operation Manual

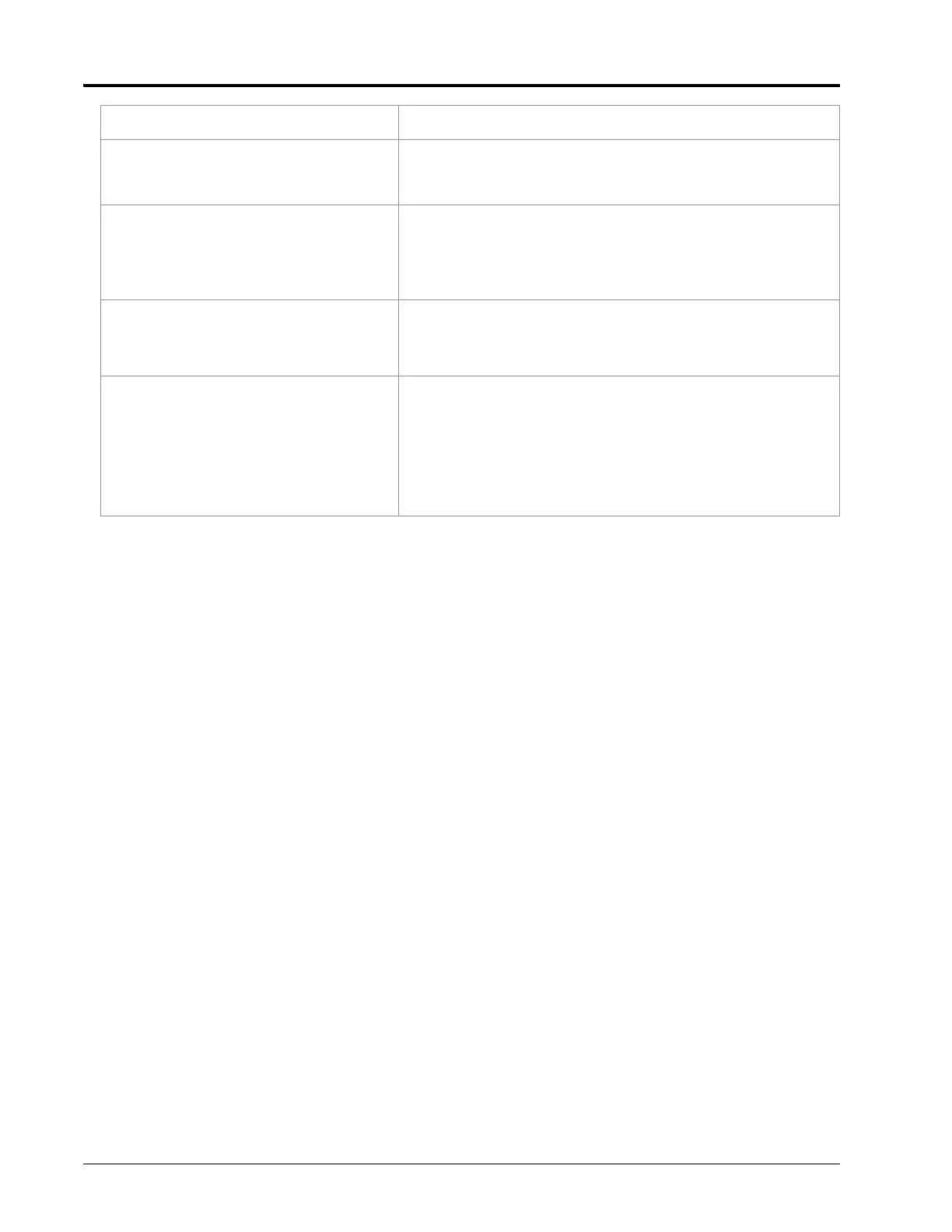

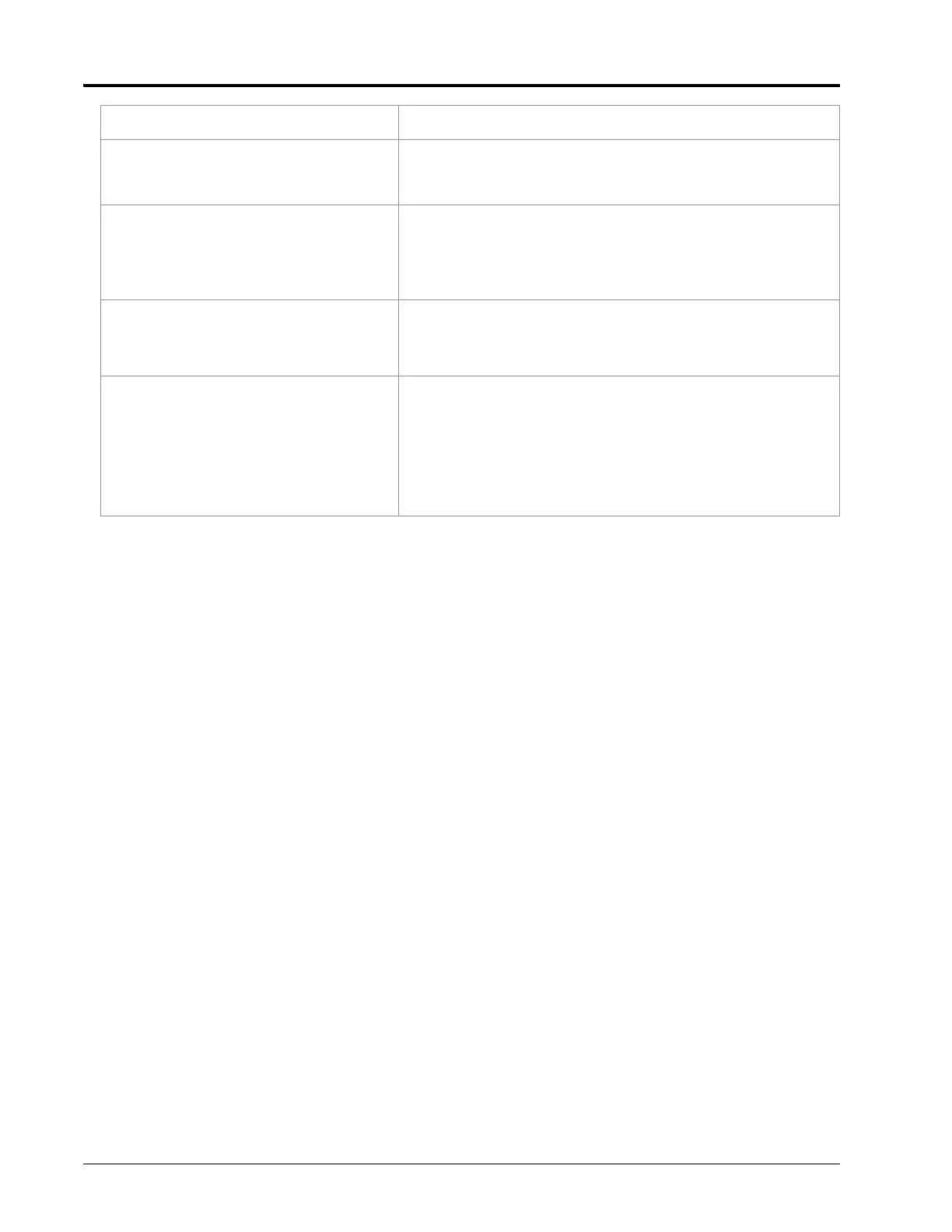

8. Water inside cover of motorized control

valve.

• Replace isolation flange assembly and coupler shaft.

• Replace entire motorized control valve if PC board or motor is

corroded and will not run.

9. Boom valve(s) will not operate. • Check cable for wires with breaks.

• Check connectors for cleanliness.

• Check BOOM switch and MASTER switch for operation.

• Replace boom valves.

10. System does not enable in ‘NH3

Applicator’ mode.

• If the control type is set to ‘NH3 Applicator’ and no proximity

switch has been installed, disable the ‘Implement Switch’ feature

on the Product Control Calibration Tab. See the Feature Settings

section on page 29 for details.

11. Boost pump pressure (AccuFlow HP

systems) does not increase or reach

target pressure.

• Refer to AccuFlow and AccuFlow HP Installation and Operation

manual for boost pump troubleshooting procedures.

• Verify that the pressure cal is calibrated correctly and the correct

target pressure is entered.

• The low limit pressure is not set correctly for operating

conditions. The low limit will shut down the system if the limit is

reached.

Problem Action

Loading...

Loading...