Paper and Other Media

61

2

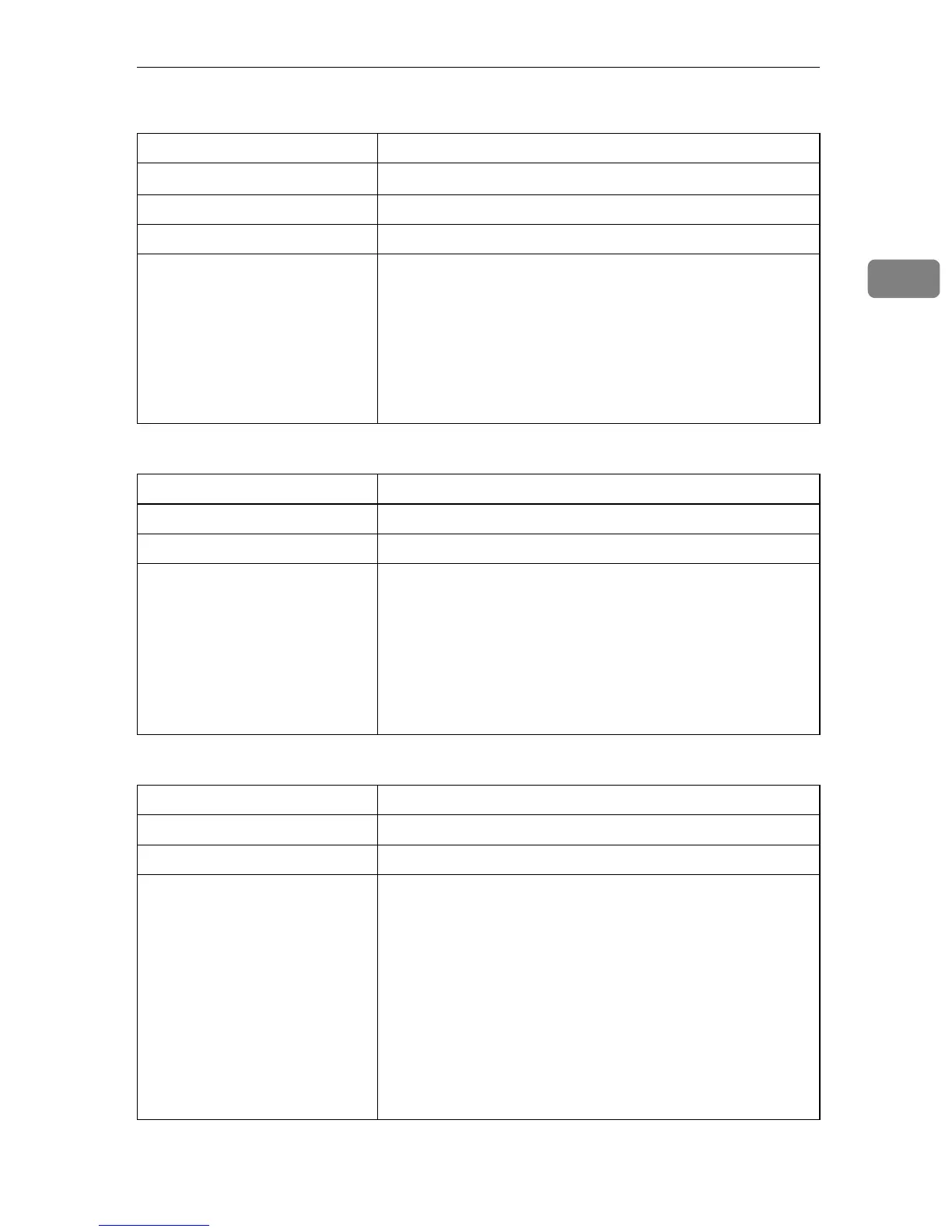

❖ Cardstock

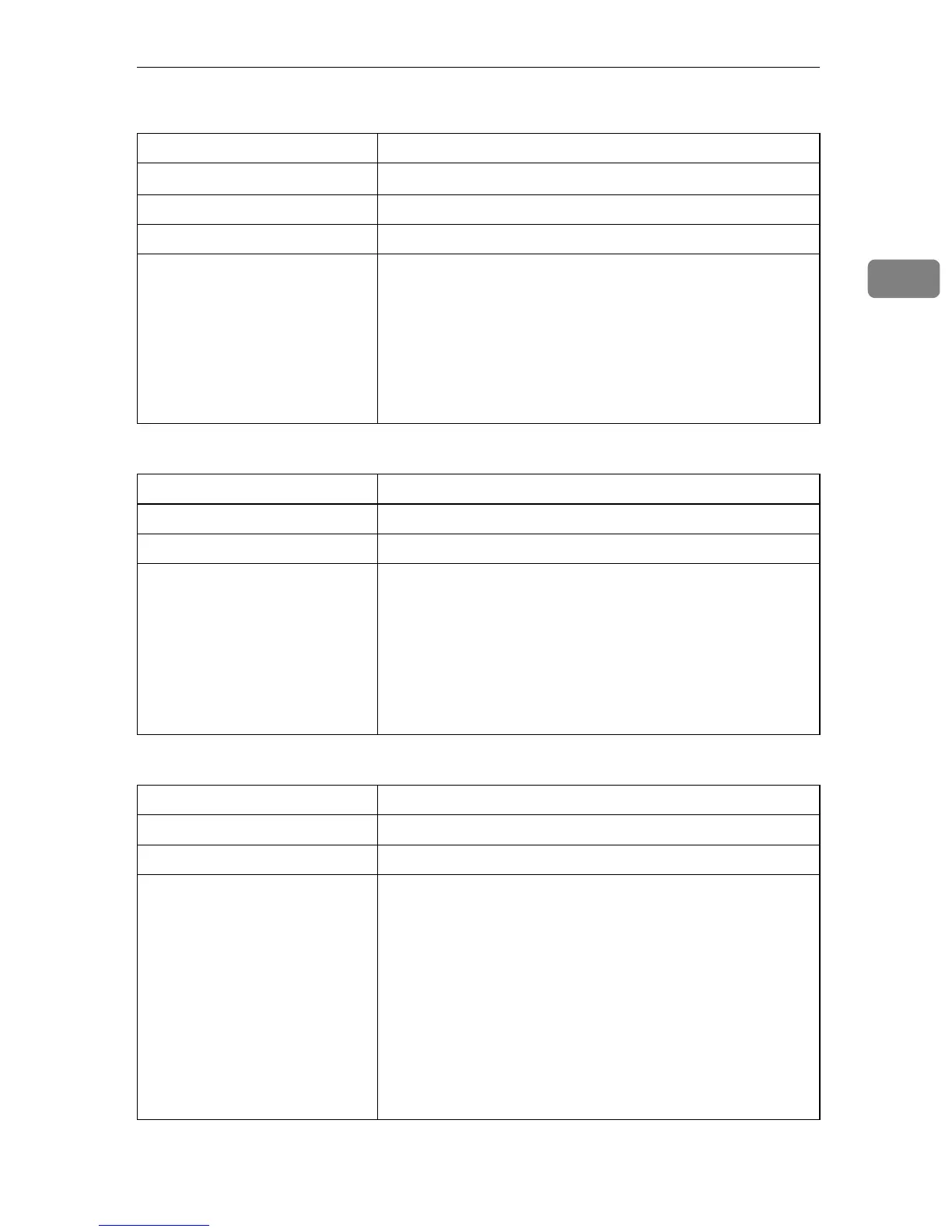

❖ Label paper

❖ OHP transparencies

Item Description

Paper thickness

105 to 160 g/m

2

(28.0 to 42.6 lb.)

Supported paper tray Tray 1 and bypass tray

Duplex supported size None

Notes • The number of sheets that can be printed in one minute is

approximately half that of plain paper.

• When using 135 g/m

2

(35.9 lb.) or heavier paper, prints

may be output with strong curls.

• When using 135 g/m

2

(35.9 lb.) or heavier paper, take

prints from the output tray frequently.

• Paper thicker than 160 g/m

2

cannot be printed onto.

Item Description

Supported paper tray Tray 1 and bypass tray

Duplex supported size None

Notes • The number of sheets that can be printed in one minute is

approximately half that of plain paper.

• Avoid using adhesive label paper on which glue is ex-

posed.

Glue may stick to the inner parts of the machine, which

can cause paper feed problems, deterioration in print

quality, or premature wear of the print cartridge's photo

conductor unit.

Item Description

Supported paper tray Bypass tray

Duplex supported size None

Notes • When loading OHP transparencies, take care not to load

them upside down. Doing so may cause a malfunction.

• It is recommended to place one sheet at a time.

• Make sure to fan OHP transparencies every time before

printing. Leaving OHP transparencies loaded in the by-

pass tray may cause them to stick together and result in a

misfeed.

• If multiple OHP transparencies are fed at the same time,

load them one by one.

• When printing on OHP transparencies, remove the trans-

parencies one by one as they are output.

Loading...

Loading...