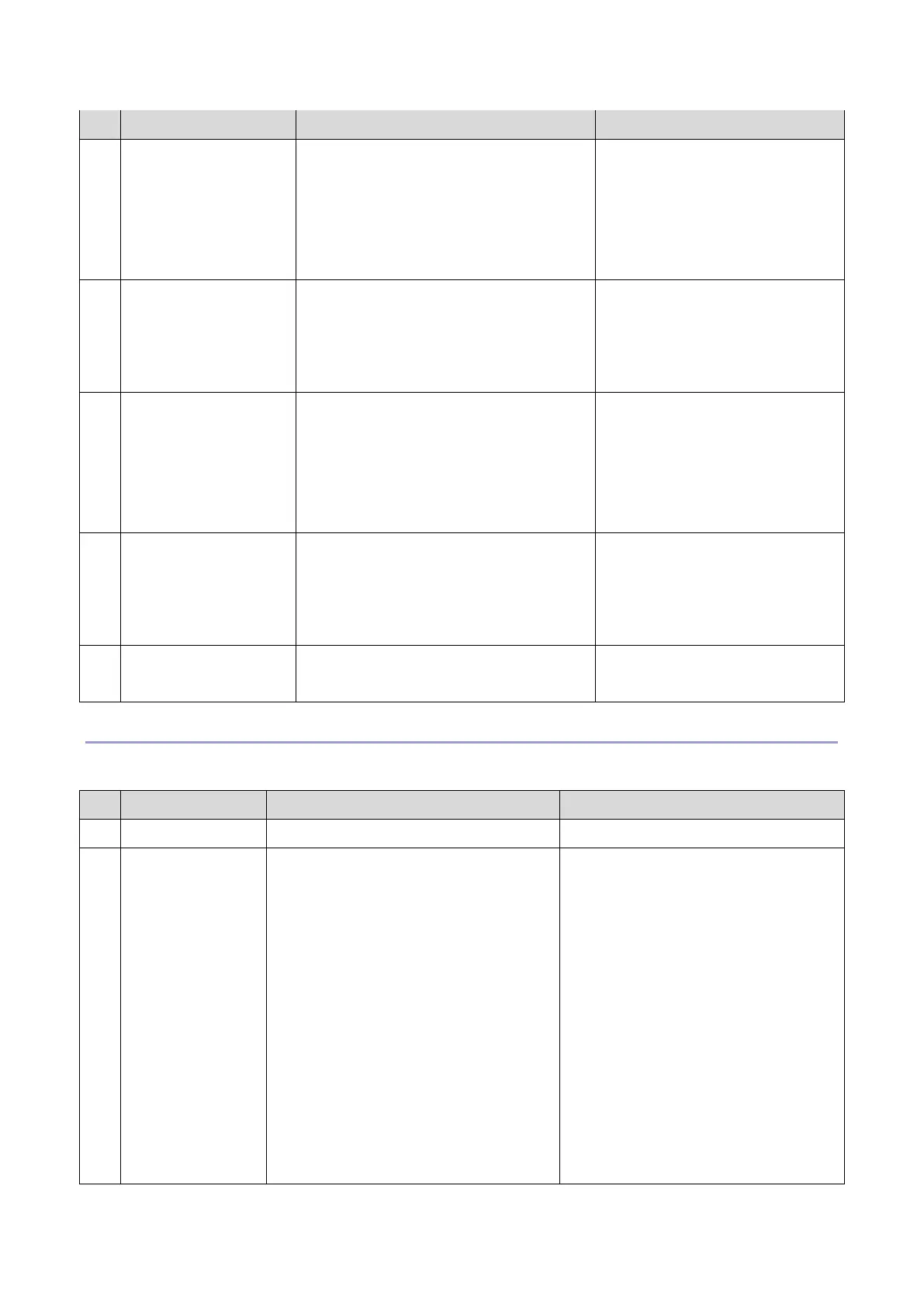

Process Control Error Conditions

501

No. Result Description Possible Causes/Action

Minimum Gamma < 0.15 too low.

• Hardware defective.

1. Same as 53

2. Replace the toner supply

pump unit.

57 Vk error: Maximum Vk is out of range.

150 < Vk

• ID sensor pattern density is

too low.

• Hardware defective.

Same as 53

58 Vk error: Minimum Vk is out of range.

Vk < –150

• ID sensor pattern density is

too high.

• Background dirty

• Hardware defective

Same as 53

59 Sampling data error

during gamma

correction

Not enough data can be sampled during

the gamma correction.

• ID sensor pattern density is

too high or low.

• Hardware defective

Same as 53

99 Unexpected error Process control fails.

• Power Failure

Check the power source.

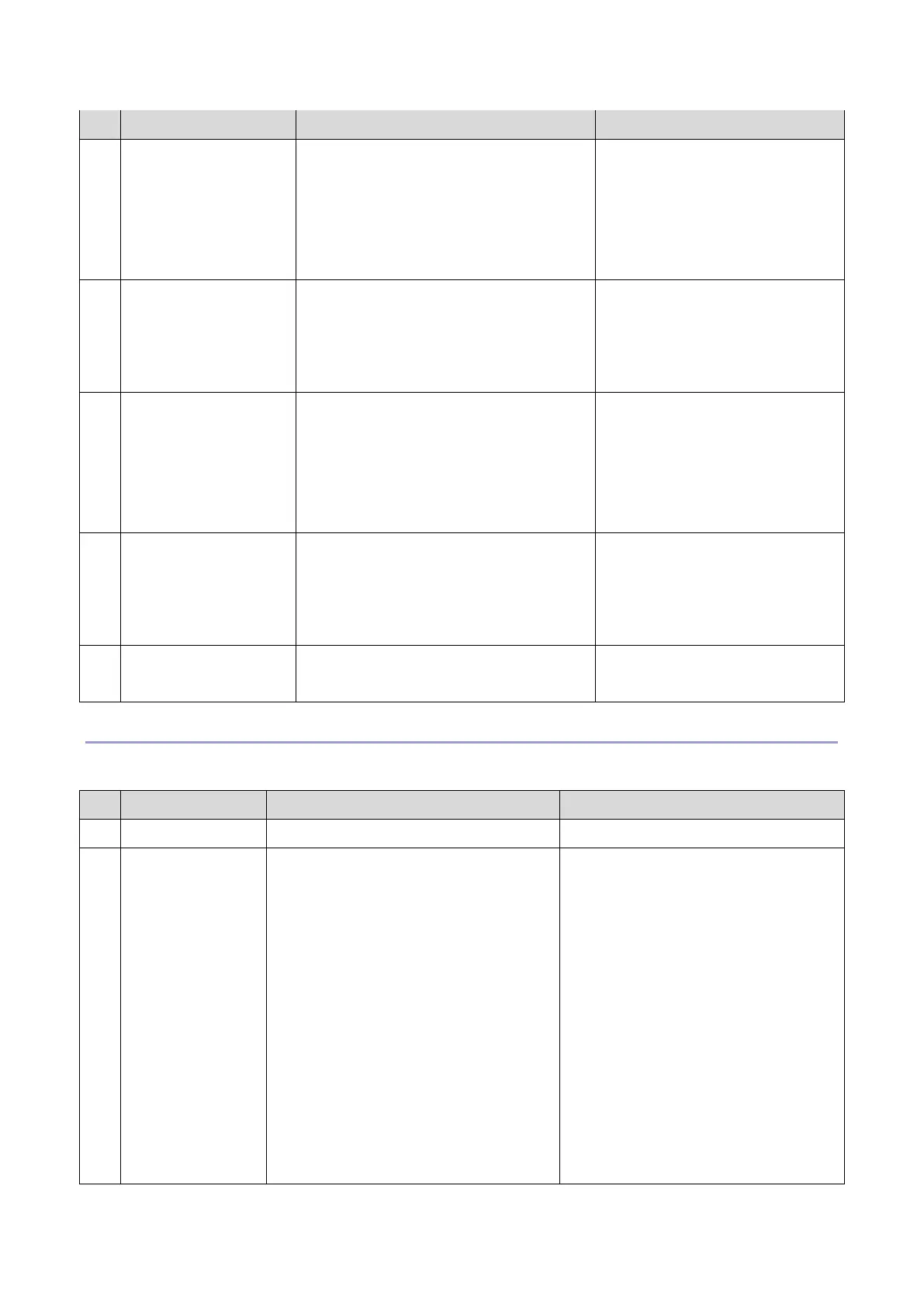

Vsg Adjustment Result

SP3-323-001 to -010 (Vsg Adjustment Result)

No. Result Description Possible Causes/Action

1 O.K Vsg adjustment is correctly done. -

2 ID sensor

adjustment error

Vsg cannot be adjusted within 4.0 ±0.5V.

• Dirty ID sensor (toner, dust, or

foreign material)

• Dirty transfer belt

• Scratched image transfer belt

• Defective ID sensor

• Poor connection

• Defective BICU

1. Clean the ID sensor.

2. Check the belt cleaning. Clean or

replace the transfer belt.

3. Replace the image transfer belt.

4. Replace the ID sensor.

Loading...

Loading...