Other Problems

M0C3/M0C4/M0C5/M0C6/M0C7 6-28 SM

6.7 OTHER PROBLEMS

6.7.1 DARK LINES IN HALFTONE AREAS AT 75MM INTERVALS

Using the machine in a room where the humidity is too low may cause dark lines in halftone

areas at 75mm intervals. This is because low-humidity conditions tend to cause variations in

light sensitivity across the surface of the drum.

Selecting [On] for [Low Humidity Mode] under [System Settings] (User Tools) may help to

prevent these lines from appearing.

When the low humidity mode setting is enabled, the drum is rotated slightly every 15 minutes.

This keeps the light sensitivity constant across the entire surface of the drum.

6.7.2 RECYCLED OR THIN PAPER IS SEVERELY CURLED AFTER

PRINTING

If the delivered paper is curled, it cannot be stacked properly. In such a case, raise the paper

stopper on the output tray and remove the paper frequently.

Setting “1” or “2” for [Interval Setting] in the SP menu may help to control the face curl of paper.

(Default: 0 (OFF))

[Interval Setting] is enabled when using normal paper or recycled paper in A4 or LT size.

Four-line LCD panel: SP menu > [Engine Maintenance] > [Interval Setting]

Touch panel: SP menu > [Engine Service Setting]

> [In

terval Setting]

When setting “1” for [Interval setting], the printing speed becomes half after printing for 1

minute.

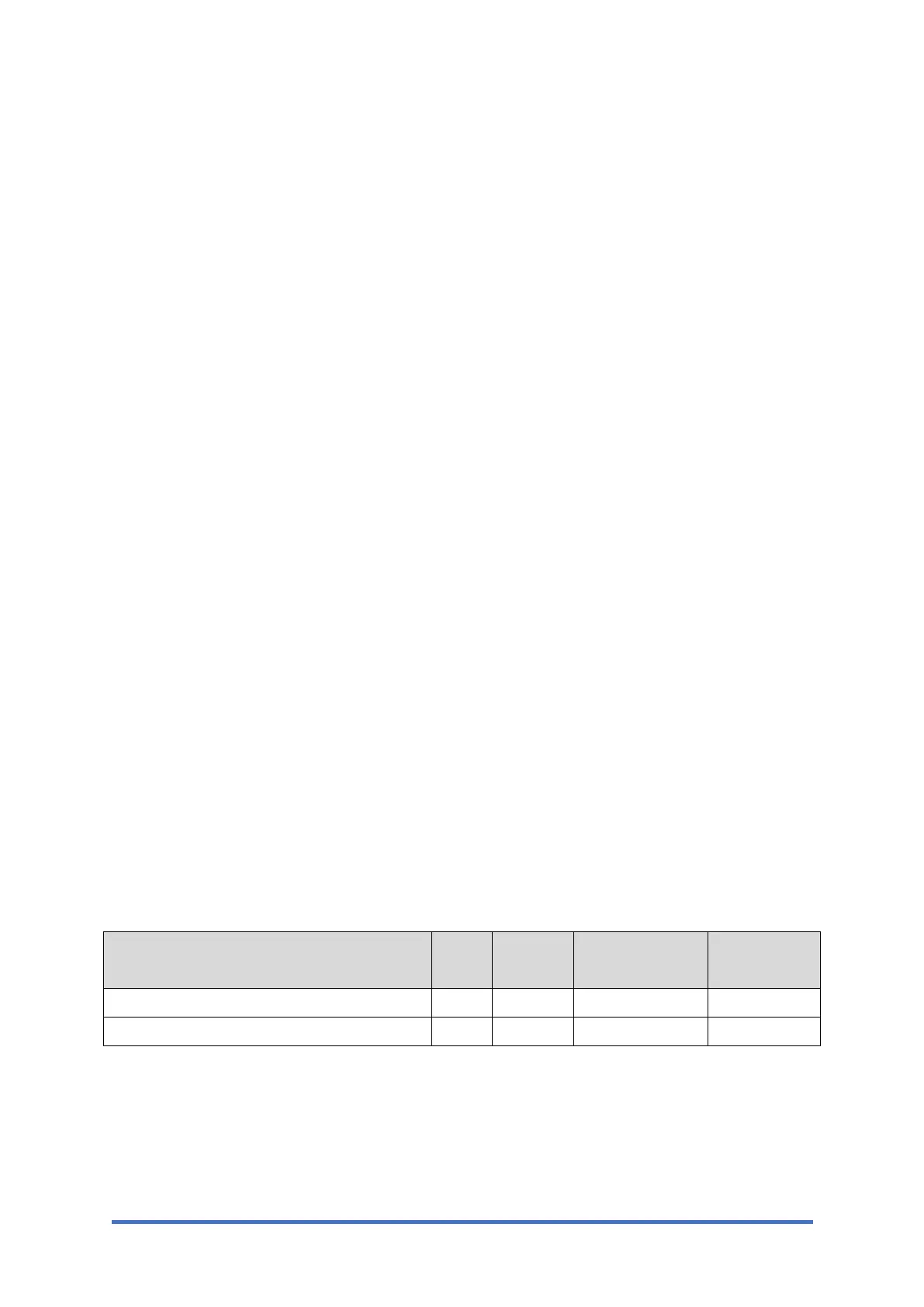

When setting “2” for [Interval setting], the printing speed becomes 13ppm. The intervals

between sheets are changed, and the service life of the parts is shortened as shown in the table

below.

PPM Interval

(mm)

Time for 1 job

(sec)

Service life

(K pages)

Normal 32 58 10.414 105

When setting “2” for [Interval Setting] 13 402 12.269 89

Loading...

Loading...