Robotiq Screwdriving Solution - Instruction Manual

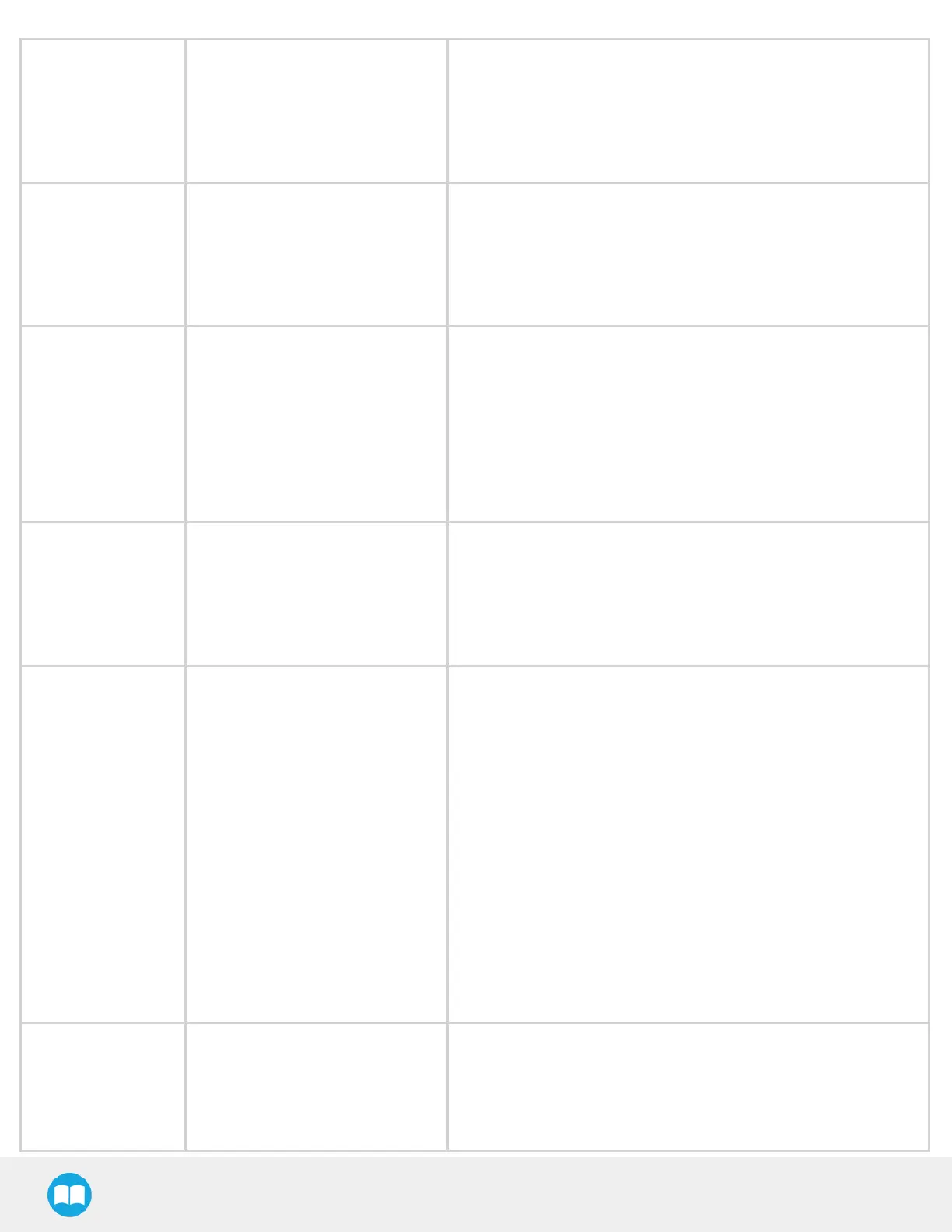

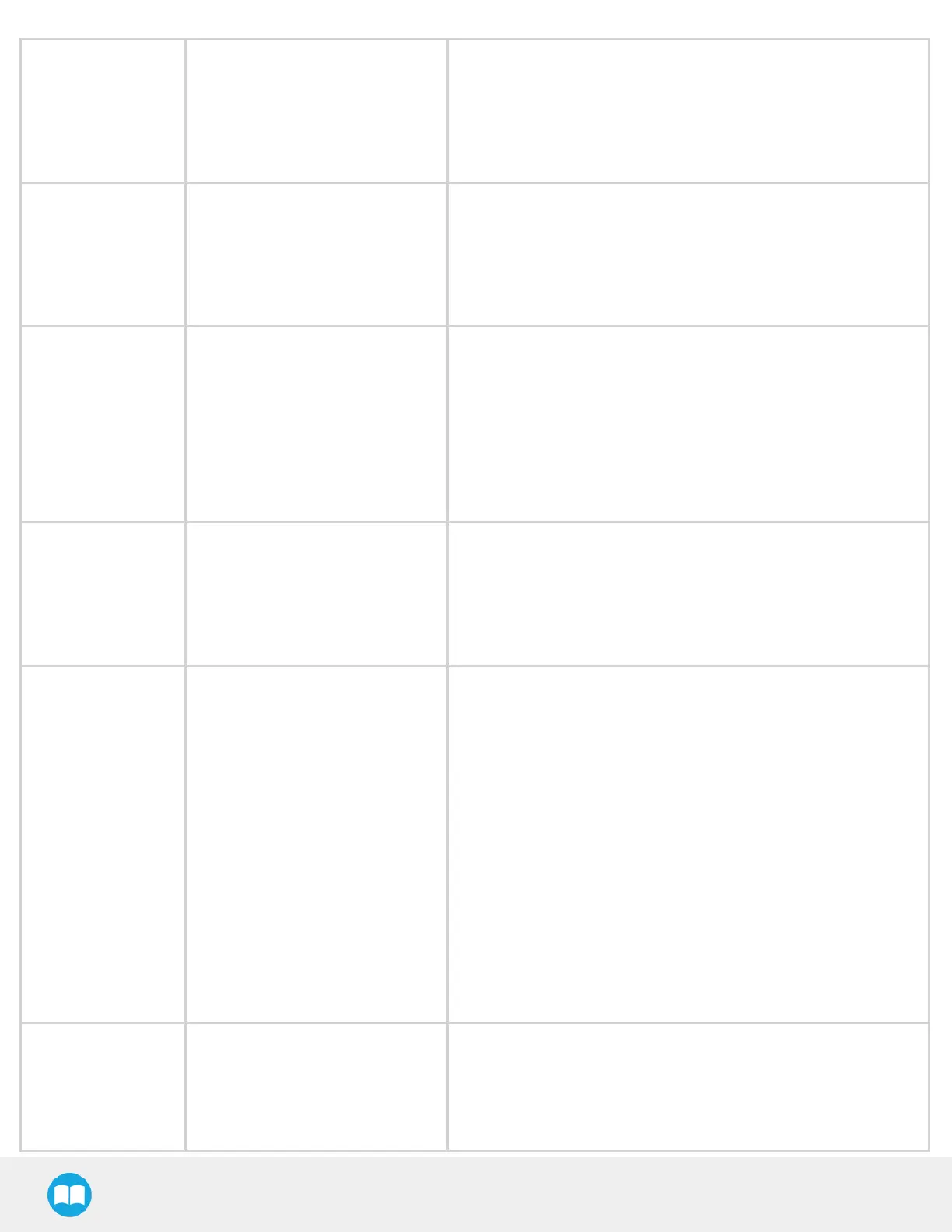

screw present

between the

singulator plates

2. Check for sensor error using the LED error codes(refer to

the ScrewFeeder Behavior section).

3. Validate if the singulator stops at the screw picking position

when the bottom sensor isobstructed. If so, screw head

height may be out of the device’s range.

Singulator does not

go to the screw

picking position or

to the rail position

The singulator moves but does

not complete the full movement

between the rail and the screw

picking position.

The LED indicator flashes red.

1. Check for blockages, and screwsthat might have fallen in

unwanted positions.

2. Check the head clearance adjustment. A loose head clear-

ance plate can cause the screw to tilt into the singulator

without fully engaging.

Screwscannot

board the rail

The screws are circulating

through the reclaiming wheel,

but are not traveling forward on

the rail.

1. Check the rail width adjustment; a rail gap that istoo nar-

row can prevent screwsfrom entering.Check for blockage; a

screw blocked on the rail can result in accumulation at the

reclaiming wheel unloading area, preventing screws from

moving forward.

2. Make sure the device islevel.

3. Make sure the screwsare within the required specifications.

Screwscannot

board the

reclaiming wheel

There are screwsin the chamber

but they are not going up the

reclaiming wheel.

1. Make sure the machine islevel.

2. Add screws in the Screw Feeder’schamber. Most of the

time, the difficulty for screws to go in the reclaiming wheel

results from an insufficient number of screws in the cham-

ber.

Screwscannot

move forward on

the rail or move

slowly

There are screwsgetting in the

rail and the reclaiming wheel is

operating normally, but the

screwsare not moving down the

rail, or are moving very slowly.

1. Check for blockage; a screw blocked on the rail can alter or

stop the vibration.

2. Make sure the machine islevel and resting on all four shoes

(rubber pads).

3. Review the Screw Feeder’sadjustments; an overtightened

rail, singulator plate or head clearance plate can prevent

the screwsfrom traveling appropriately.

4. Check that the chamber iscorrectly filled; too many screws

(over the max fill line) can prevent the rail from vibrating

properly.

5. Verify that the rail knob isclear from any interference, such

asa wall or a vertical surface; since this component vibrates

along with the rail, an external impediment can prevent the

screwsfrom moving forward.

Incorrect screws are

coming out of the

rail system

Incorrectly positioned screwsare

not sorted by the Screw Feeder

and are fed to the singulator.

1. Verify the Screw Feeder’sadjustments. A too low or too

high brush or head clearance plate can cause incorrectly

positioned screwsto travel to the singulator.

2. Verify that your screw iswithin the specified range.

90

Loading...

Loading...