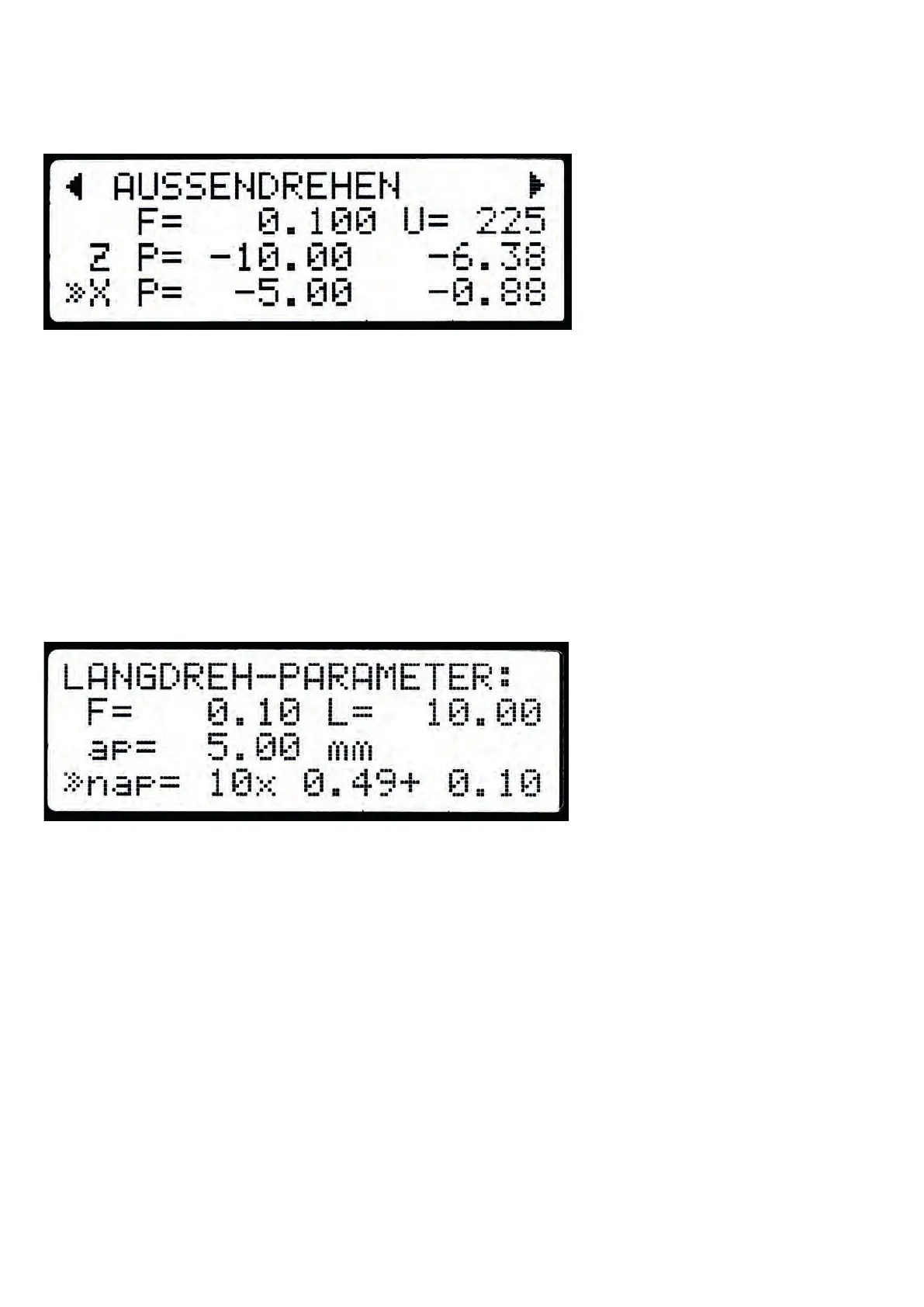

External turning in several passes Example:

Selected are ZP= -10 and XP = -5

It should therefore remove 5mm of material, over a length of 10mm.

After starting the spindle and pressing START, the control rst calculates the number of passes

required. The set values for Maximum roughing thickness (X Ap roughing) and Finishing thick-

ness (X Ap nishing) are used. This means that n passes are run with maximum roughing thick-

ness, the last pass with nishing thickness. In principle, the last pass always takes place with

nishing feed! The set value of the roughing thickness is not exceeded.

> In this example, X Ap Rough is set to 0.5mm and X Ap Finish is set to 0.1mm.

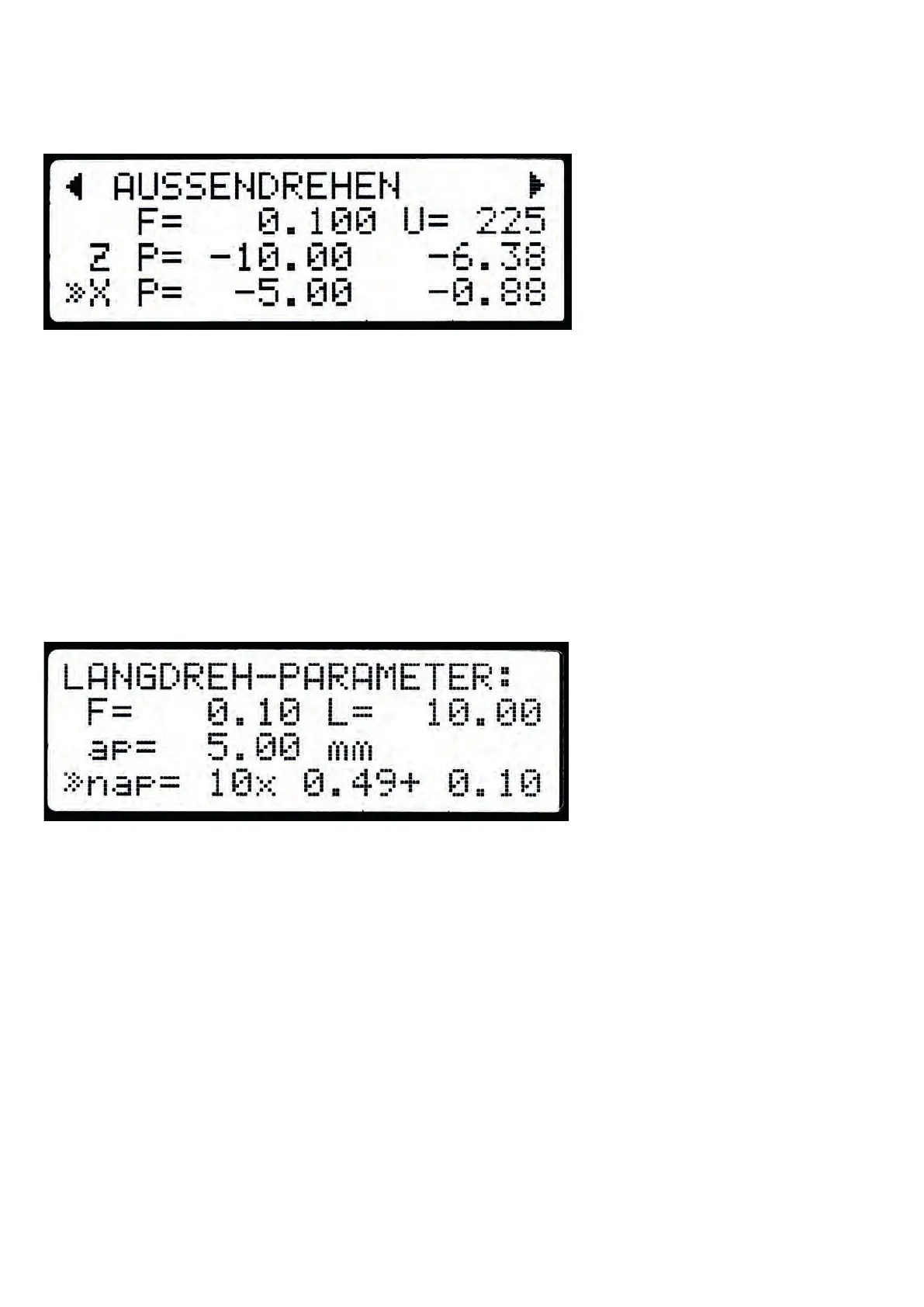

The display will then be as follows

What is displayed here?

F = 0,10 The feed in mm/revolution

L = 10,00 The length of the cut in Z-direction

ap = 5,00 The total decrease of material thickness in X-direction

nap = 10x 0,49 + 0,10 The number of roughing passes and the strength of the last

nishing pass. (nap = n x Ap)

So here 0.49mm are to be removed in 10 passes, the last pass is done with a nishing thickness

of 0.10 mm. In total this results in a value of ap=5.00 mm. The total number of passes is 11: 10x

roughing and 1x nishing.

Use the rotary knob to change the number of passes up or down, the cutting depths will be

recalculated on-the-y. This allows you to make changes quickly, but you must be careful

not to overload the machine or material with excessive cutting depths. You can also reduce

the number of passes to 1, then it will move directly to the end point, useful e.g. if you want

to move one last pass to the maximum depth. If you like the values, press START to start the

process. STOP cancels the process.

60

Loading...

Loading...