Reference Manual

00809-0100-4809, Rev DA

Appendix B: Product Certifications

September 2015

226

Product Certifications

IA ATEX FISCO

Certificate: Baseefa08ATEX0129X

Standards: EN60079-0:2012, EN60079-11:2012

Markings: II 1 G Ex ia IIC T4 Ga (-60 °C

T

a

+60 °C)

Special Conditions for Safe Use (X):

1. If the equipment is fitted with an optional 90 V transient

suppressor, it is incapable of withstanding the 500 V

isolation from earth test and this must be taken into

account during installation.

2. The enclosure may be made of aluminum alloy and

given a protective polyurethane paint finish; however

care should be taken to protect it from impact and

abrasion when located in Zone 0.

N1 ATEX Type n

Certificate: Baseefa08ATEX0130X

Standards: EN60079-0:2012, EN60079-15:2010

Markings II 3G Ex nA IIC T4 Gc (-40 °C

T

a

+70 °C)

Special Condition for Safe Use (X):

1. If the equipment is fitted with an optional 90 V transient

suppressor, it is incapable of withstanding the 500 V

electrical strength test as defined in clause 6.5.1 of by

EN 60079-15:2010. This must be taken into account

during installation.

ND ATEX Dust

Certificate: Baseefa08ATEX0182X

Standards: EN60079-0:2012, EN60079-31:2009

Markings: II 1 D Ex ta IIIC T95 °C T

500

105 °C Da

(-20 °C

T

a

+85 °C)

Special Condition for Safe Use (X):

1. If the equipment is fitted with an optional 90V transient

suppressor, it is incapable of withstanding the 500V

isolation from earth test and this must be taken into

account during installation.

International

E7 IECEx Flameproof

Certificate: IECExKEM08.0024X

Standards: IEC60079-0:2004, IEC60079-1:2007-04,

IEC60079-26:2006

Markings: Ex d IIC T6/T5 IP66, T6(-50 °C

T

a

+65 °C),

T5(-50 °C

T

a

+80 °C)

Special Conditions for Safe Use (X):

1. The device contains a thin wall diaphragm. Installation,

maintenance and use shall take into account the

environmental conditions to which the diaphragm will

be subjected. The manufacturer’s instructions for

maintenance shall be followed in detail to assure safety

during its expected lifetime.

2. The Ex d blanking elements, cable glands, and wiring

shall be suitable for a temperature of 90 °C.

3. In case of repair, contact the manufacturer for

information on the dimensions of the flameproof joints.

I7 IECEx Intrinsic Safety

Certificate: IECExBAS08.0045X

Standards: IEC60079-0:2011, IEC60079-11:2011

Markings: Ex ia IIC T4 Ga (-60 °C

T

a

+70 °C)

Special Conditions for Safe Use (X):

1. If the equipment is fitted with an optional 90 V transient

suppressor, it is incapable of withstanding the 500 V

isolation from earth test and this must be taken into

account during installation.

2. The enclosure may be made of aluminum alloy and

given a protective polyurethane paint finish; however

care should be taken to protect it from impact and

abrasion when located in Zone 0.

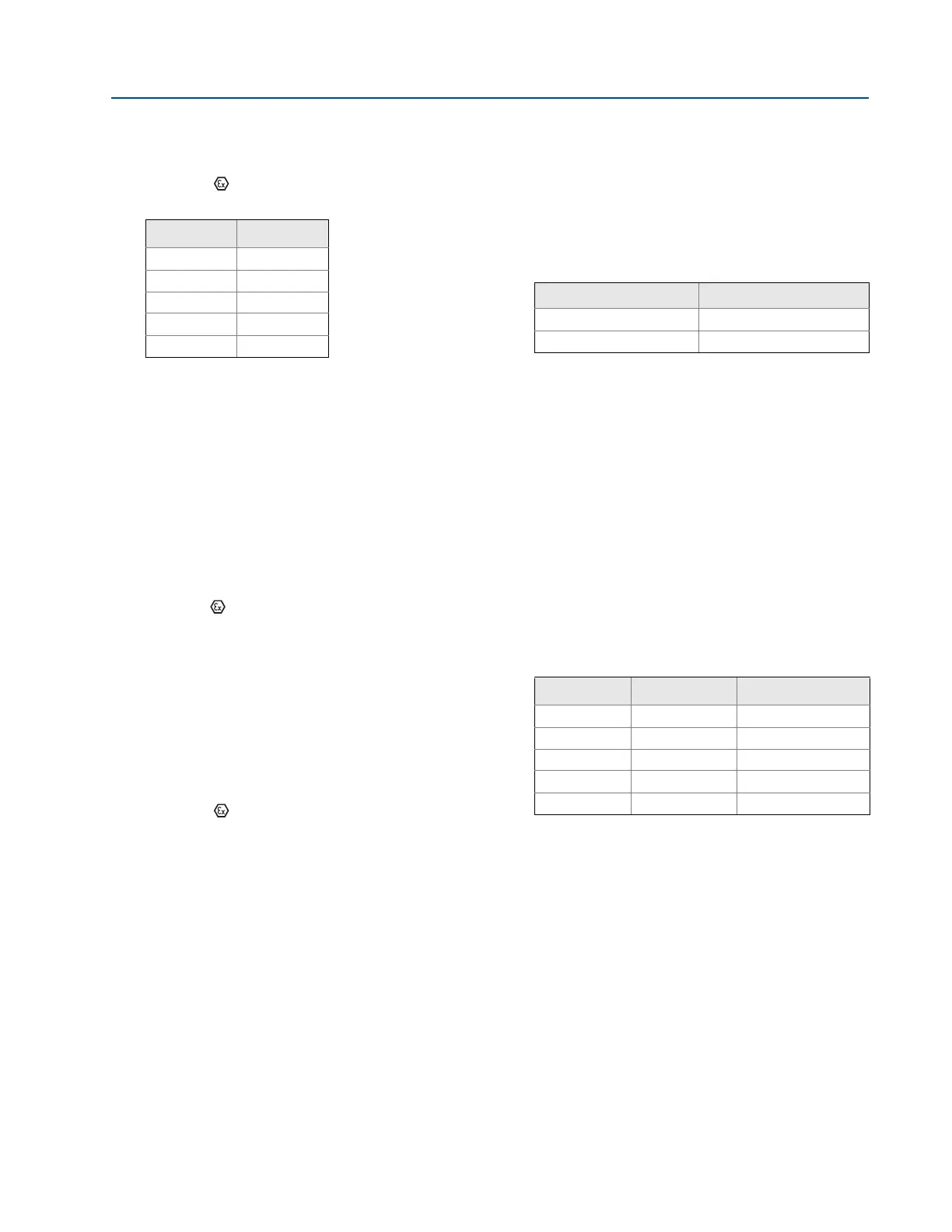

Table 12. Input Parameters

Parameters

FISCO

Voltage U

i

17.5 V

Current I

i

380 mA

Power P

i

5.32 W

Capacitance C

i

< 5 nF

Inductance L

i

< 10 F

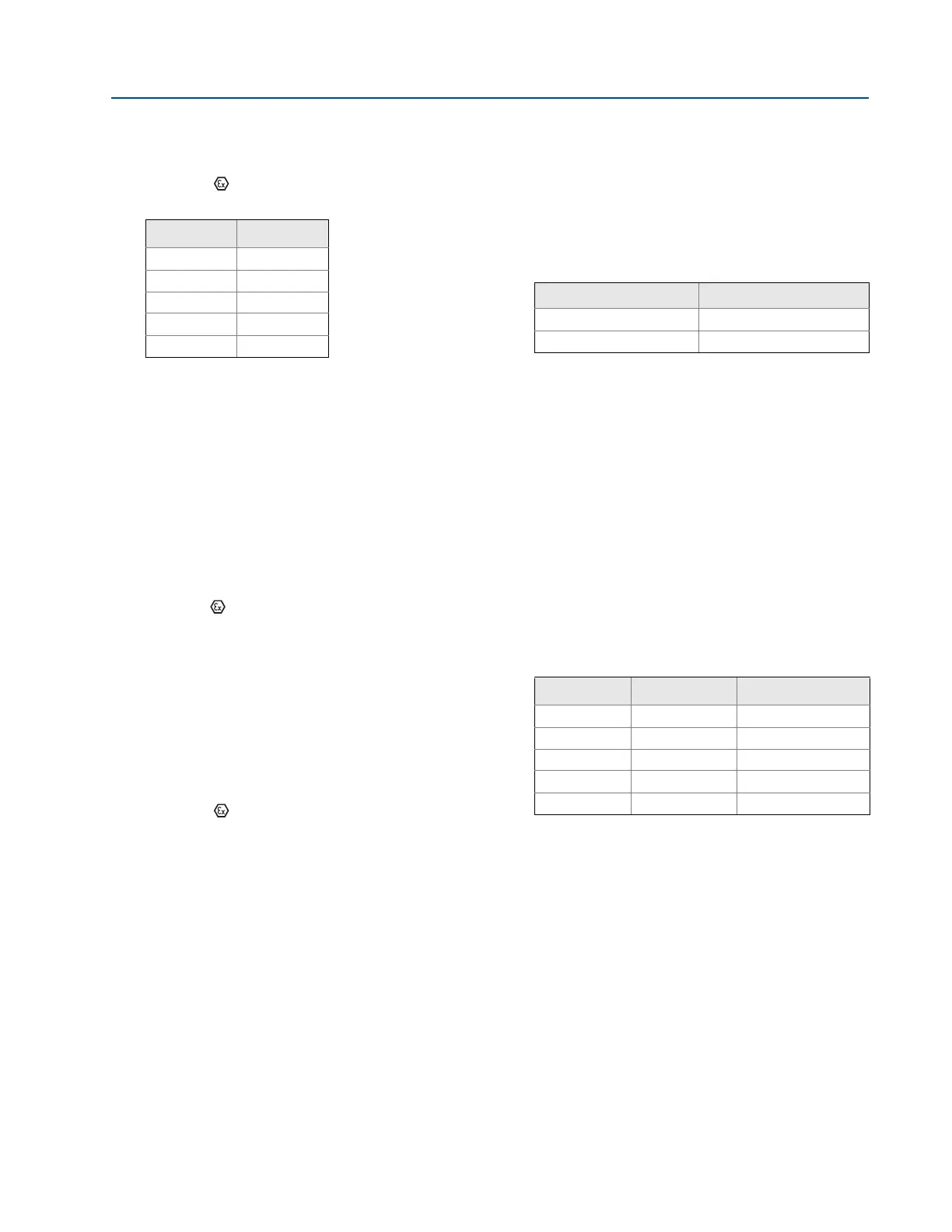

Table 13. Process Temperature

Temperature class Process temperature

T6 -50 °C to +65 °C

T5 -50 °C to +80 °C

Table 14. Input Parameters

Parameters

HART Fieldbus/PROFIBUS

Voltage U

i

30 V 30 V

Current I

i

200 mA 300 mA

Power P

i

1 W 1.3 W

Capacitance C

i

0.012 F 0 F

Inductance L

i

0 mH 0 mH

Loading...

Loading...