76-00-00

page 46

May 01/2007

Effectivity 914 Series

Edition 1 / Rev. 0

d02626

BRP-Rotax

Maintenance Manual

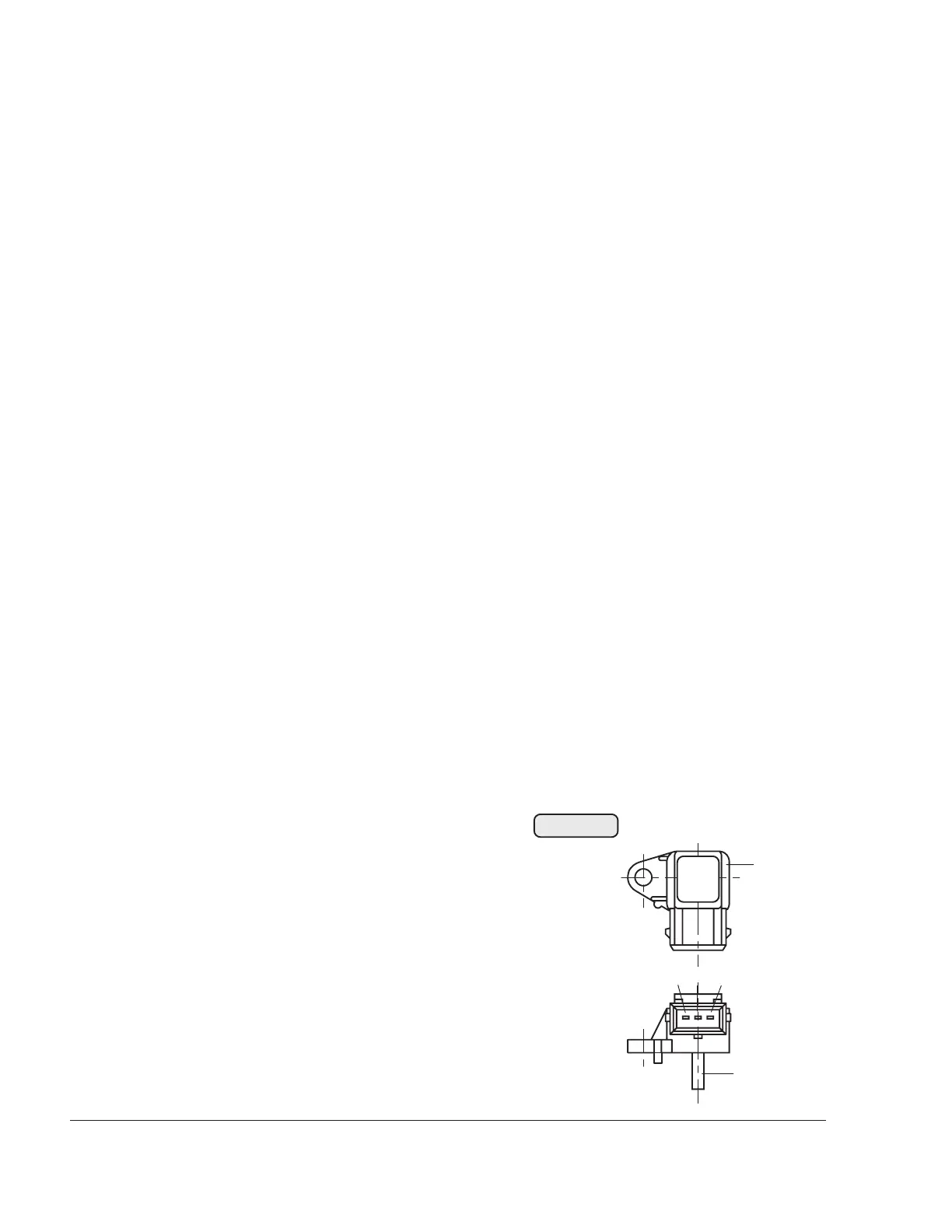

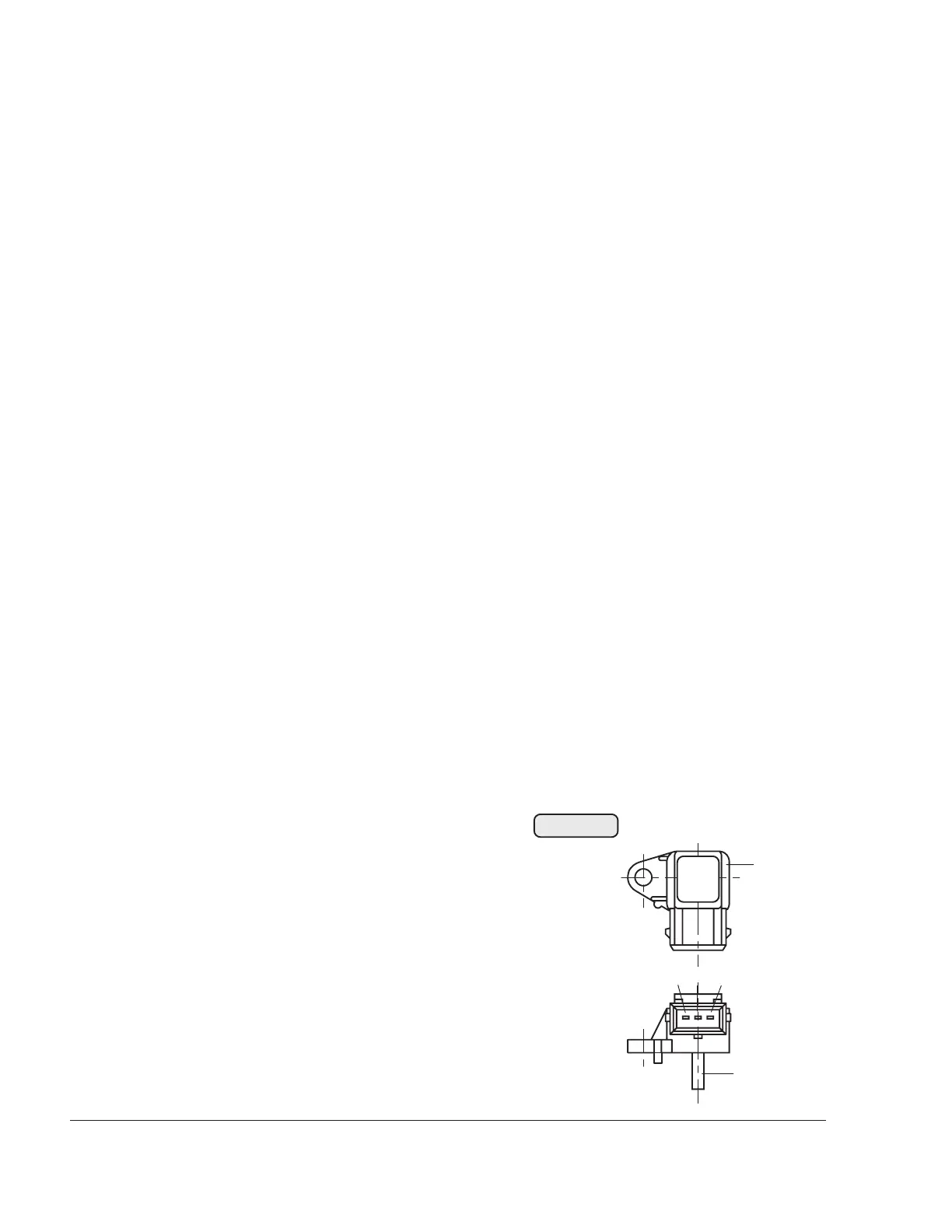

a) Airbox pressure sensor:

See Figs. 76-44 and 76-45.

On engines with an airbox of older configuration, the installa-

tion location of the airbox pressure sensor (2) depends on the

aircraft type and is limited by the length of the wiring harness.

On engines with an airbox of newer configuration, the airbox

pressure sensor (2) is integrated in the airbox. See SI-914-013

and SI-914-015, “Introduction of a new airbox“, latest issue.

■ CAUTION: The sensor is designed for a pressure range of

500 hPa to 2500 hPa and max. pressure must

not exceed 3500 hPa.

If the max. pressure is exceeded during the course of measur-

ing, the sensor must be replaced.

When taking the following readings, the plug connection to the

wiring harness must be disconnected and reestablished im-

mediately after completion of the checks. The same applies for

the air pressure hose.

The easiest way to check the function of the two pressure

sensors is to use the communication program. If this program

is not at your disposal, the following static checks can be

carried out.

- Inspect for physical damage.

- Static check for function of airbox pressure sensor:

Allocation of connections for

test set-up / legend to Fig. 76-44

(3) Measuring voltage output Ua

(4) Ground (øV)

(5) Voltage supply Us

min. + 3 V, max. + 15 V

(6) Pressure connection

00058

966 502

airbox

pressure

2

345

6

Fig. 76-44

Loading...

Loading...