Effectivity 914 Series

Edition 1 / Rev. 3

76-00-00

page 59

October 01/2010

d04780

BRP-Powertrain

Maintenance Manual

06750

Motor / Engine type:

___________

Motor / Engine serial no.:

___________

TCU Serien-Nr.

TCU serial no.

____________

TCU Teile Nr.

TCU part no.:

____________

TCU Programmversion

TCU Program-Version:

Sichtkontrolle:

Visual check:

____________

Prüfdongle, Serien-Nr.:

Check dongle, serialno.:

____________

Prüfung mit:

Check with:

Vergaser 2/4, Serien-Nr.:

carburetor 2/4, serial no.:

____________

ROTAX Testkoffer am Motor

ROTAX testcase on engine

Unterschrift Prüfer / Signature Tester

:

_____________

Datum

/

Date:

________

Bemerkungen / Remarks

: ______________________________

__________________________________________________

__________________________________________________

__________________________________________________

__________________________________________________

TSN:

______

TSO: ______

Lampenkontrolle / lamp control

Lampen

leuchten beim Einschalten:

lamps

flash during switch on:

gelbe Lampe rote Lampe

yellow lamp red lamp

Anreicherungsventilkontrolle / solenoid control

Solenoid

schaltet bei :

solenoid

operates at :

1250 mbar

(966 470)

Over Boost-Kontrolle /

over-boost-control

rote Lampe

leuchtet bei :

red lamp

flashes at :

O.K.

Airboxdruck >1550 mbar

airbox pressure >1550mbar

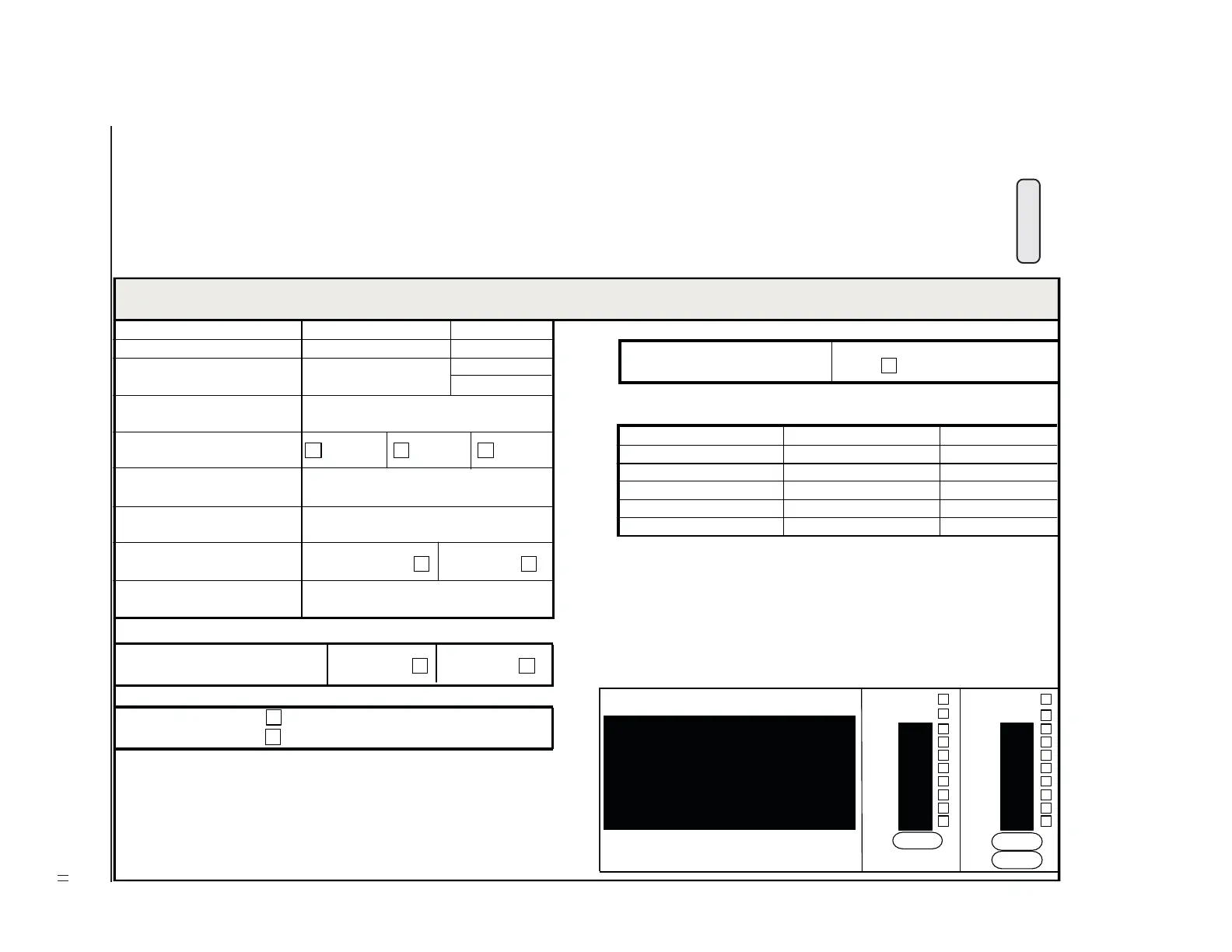

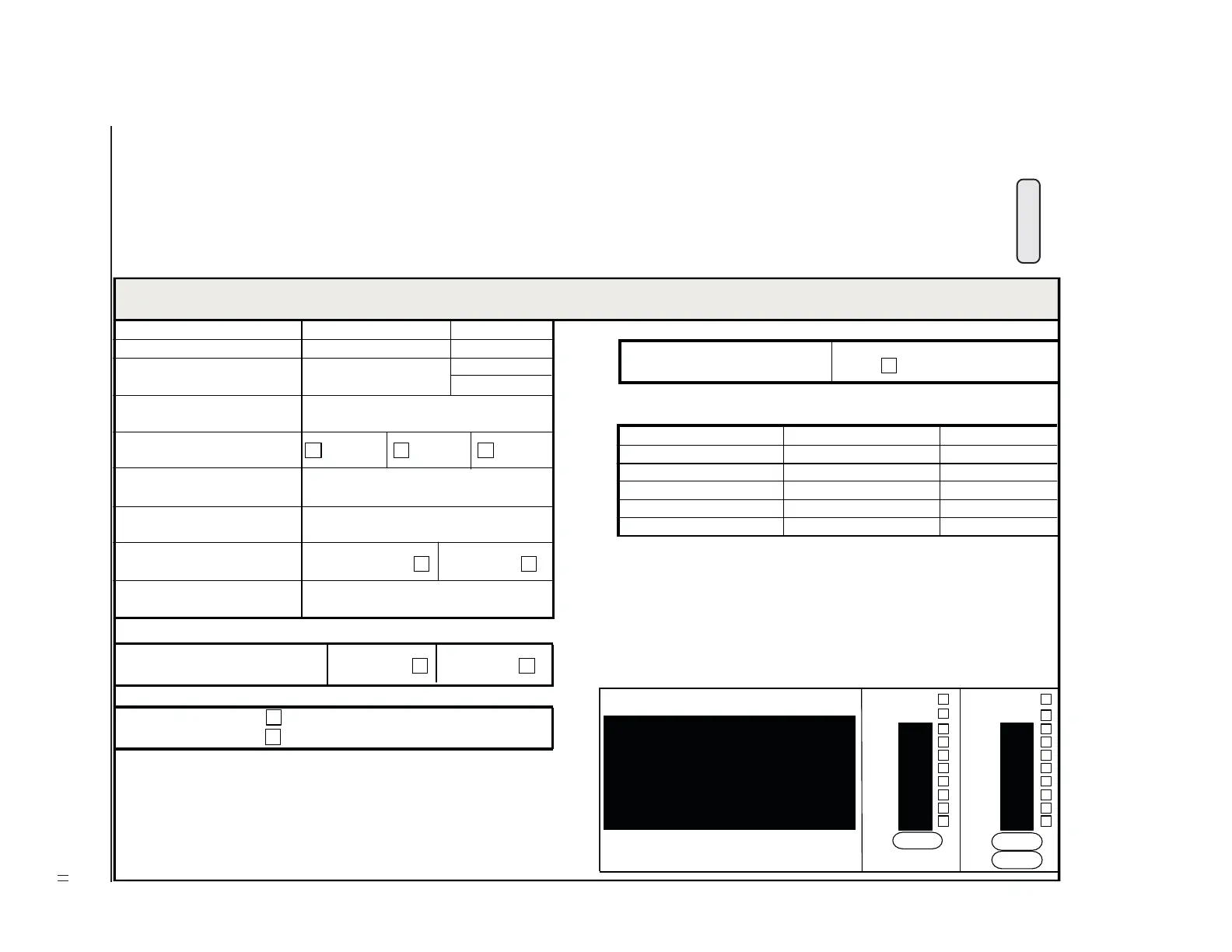

Prüfprotokoll für Turboladerregler / Inspection protocol for turbo charger control unit

Plausibiltäts-Kontrolle /

plausibility-control

(MONITOR-Oberfläche / MONITOR-menu)

LOAD

1)

(idle) : 0È %

(Sollwert/target value)

_________

%

LOAD

1)

(full) : 115 %

(Sollwert/target value)

_________

%

ambient pressure

2)

:

_________

mbar

airbox pressure

2)

:

_________ mbar

airbox temperature

3)

:

_________ °C

servoposition (idle)

4)

:

100 %

±

3 (Sollwert/target value)

_________

%

1)

lineare Kennlinienverlauf /Linear values of load

2)

+/- 10 mbar Differenz der beiden Werte (vgl. Tagesdruck) /

+/- 10 mbar difference between the two values (compare actual pressure of the day)

3)

die Temperatur sollte in etwa der Umgebungstemperatur entsprechen /

temperature should be equal to ambient temperature

4)

Servoposition bei IDLE = 100% Servoposition = Waste-Gate geschlossen /

Servoposition at IDLE = 100% servoposition = Waste-Gate closed

Kalibrier-Kontrolle /

calibration-control

966470 966473

966741

TSN:

______

TSO: ______

1260 mbar

(966 473 / 966 741)

Airboxdruck

Airbox pressure

10

1003

60

710

12219

250

6720

-37

60

900

60

710

12219

250

6720

-37

TLR 4.3

TLR 4.5

TLR 4.6

TLR 4.3 TLR 4.5 TLR 4.6

Servo OFFSET ....................................................................

Servo RANGE ....................................................................

Throttle OFFSET ..................................................................

Throttle RANGE ..................................................................

Airbox pressure sensor calibration parameter A ................

Airbox pressure sensor calibration parameter B ................

Ambient pressure sensor calibration parameter A ..............

Ambient pressure sensor calibration parameter B ............

966471

Mit neuem Umgebungsdrucksensor / With new ambient pressure sensor

+60 mbar (+/- 10 mbar) Differenz der beiden Werte (vgl. Tagesdruck) /

+60 mbar difference between the two values(+/- 10 mbar)

Fig. 76-53

4) Form Sheets

Loading...

Loading...