Chapter 2 General notes for service technicians

SMSO-2-02.02- 15.07.03 25

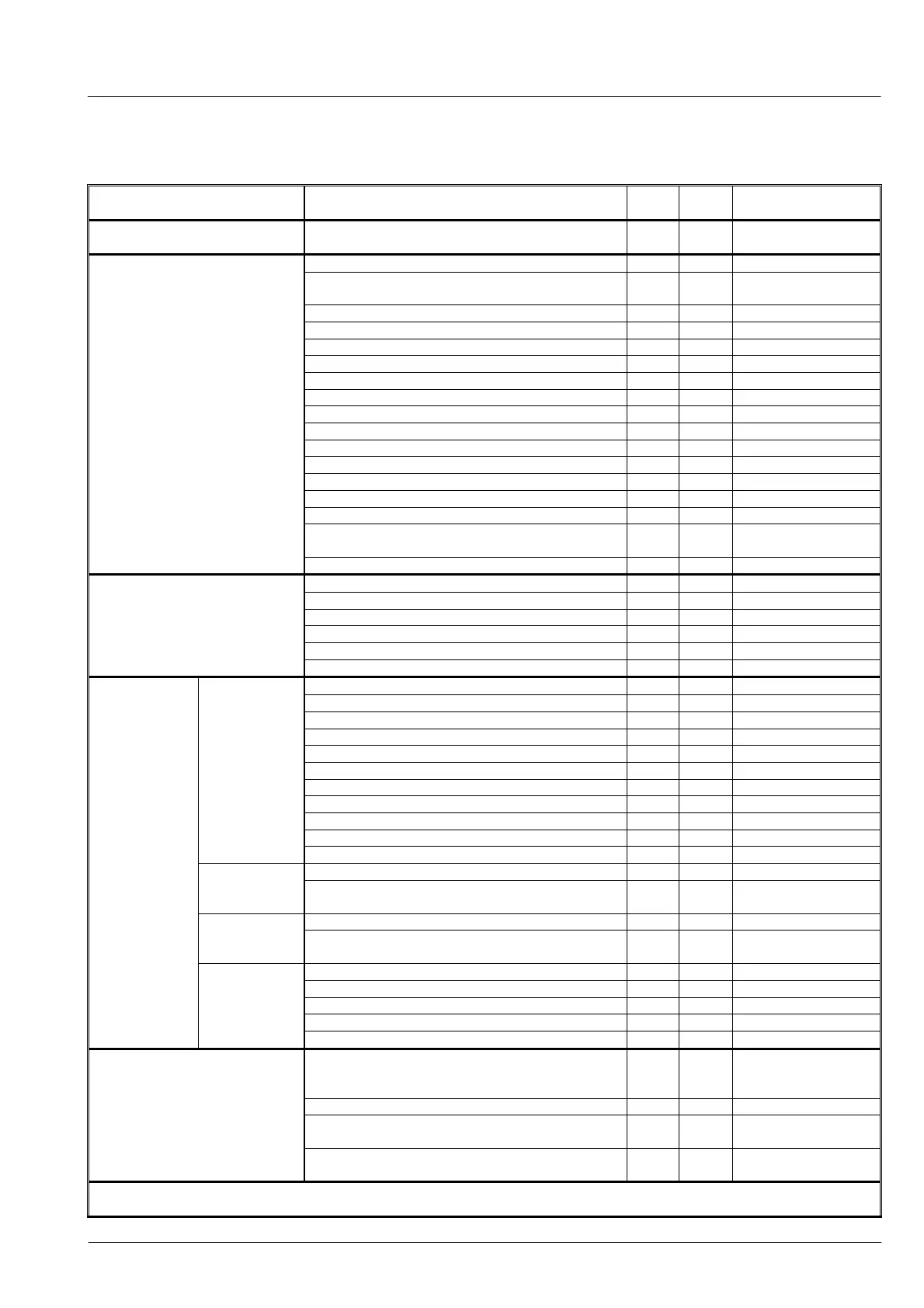

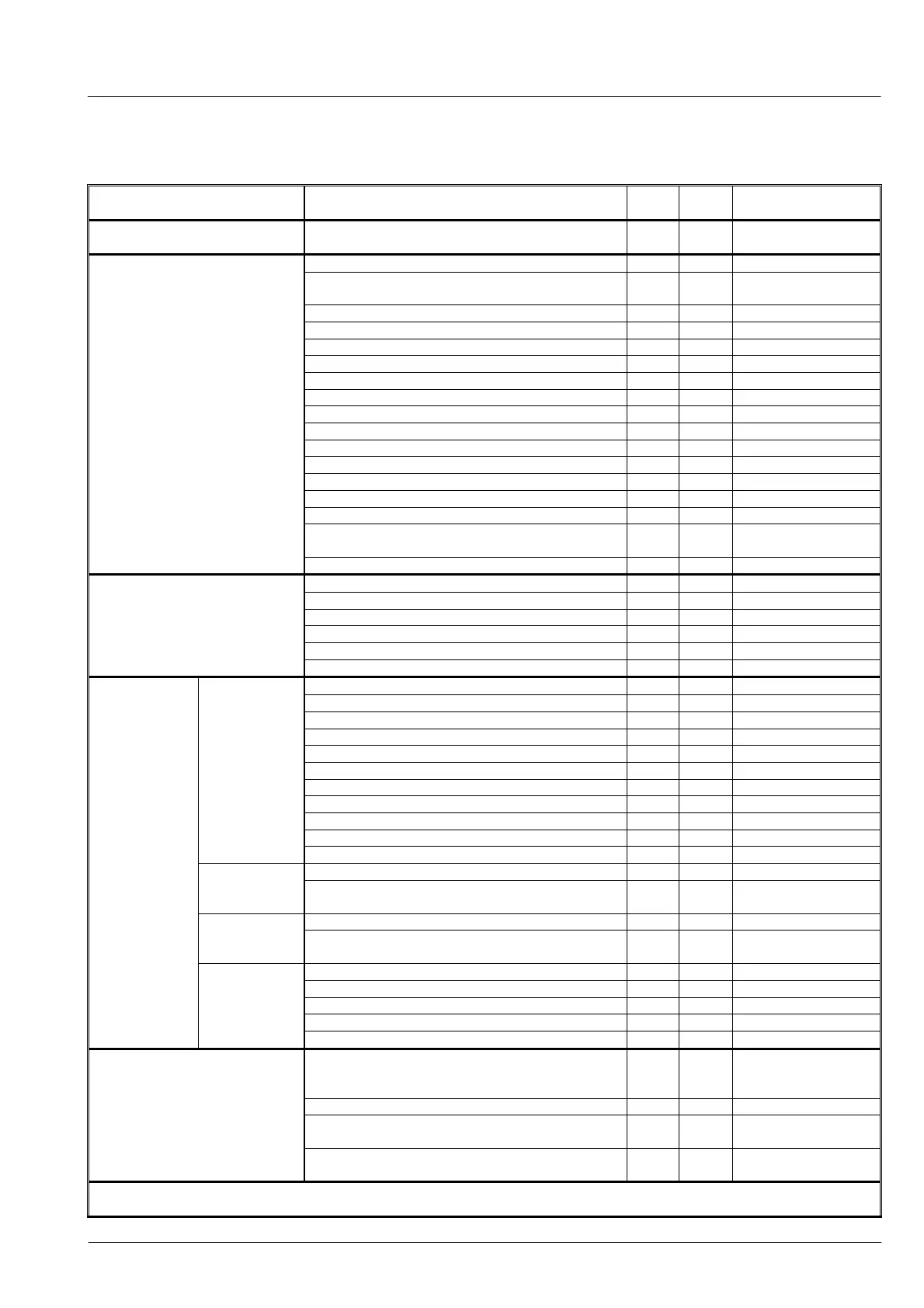

Systematic machine check

The check should be made consistently according to the following list

Check

Description Yes No Statement

Measure(s) to take

Service documents

Sight of: service documents and inspection re-

ports

Bean container

Cup plate and casing on left-hand and right-hand

sides

Control panel / display

Ventilators

Card reader, coin locking device

Outlet trolley, function brake rubber

Hot water / steam outlet

Front cover

Drip tray (residues)

Grounds container / container area

Consistency / moisture content of grounds

Refrigerator / door closure / temperature setting

Quick cup warmer

Environment (standing surface / trolley etc.)

Main switch / mains cable / mains input

Water connection / connection tube / condition of

filter

External visual check of

cleanliness and mechanical

defects

Waste water pipe / waste water container

Local pressure: Manometer

Heating up; temperature on display unit; time

Safety valves: Function?

Check pump pressure?

Display messages

Switch on from cold:

Noise emissions

Grinder: Noise emission

Size of coffee grain

Grinding time

Rotary-vane type pump: Noise emission

Manometer: Brewing pressure

Brewing unit: Noise emission

Outlet: Speed / uniformity

Foam: Colour and consistency

Quantity of product dispensed

Quality of product: Temperature (subjective)

• Coffee

Quality of product: Taste (subjective)

Manometer: System pressure

• Tea

(alternative/

additionally

Quality of product: Temperature (subjective)

Quality of product

• Steam

(alternative/ad

ditionally

Steam nozzle: Speed and quantity of outflow

Refrigerator / foamer head Noise emission

Quality of product: Consistency and volume

Quality of product: Temperature

Outlet: Speed / uniformity

Test: Product

serving

(servings) and

assessment

of:

• Milk/milk

foam/

(alternative/

additionally)

Rinsing process Quantity and outlet time

Check meter readings and enter into service

documentation. Decide which components need

to be replaced immediately.

Programming/accessories

Check settings relating to the likely fault

Check water consumption meter and any related

settings (blend parameters)

Check/replace/supply accessories (powder brush,

O-rings etc.)

NOTE: A minimum of the visual check must be carried out on machines where the faults are such that they can no

longer be operated.

Loading...

Loading...