Chapter 2 General notes for service technicians

26 SMSO-2-02.02- 15.07.03

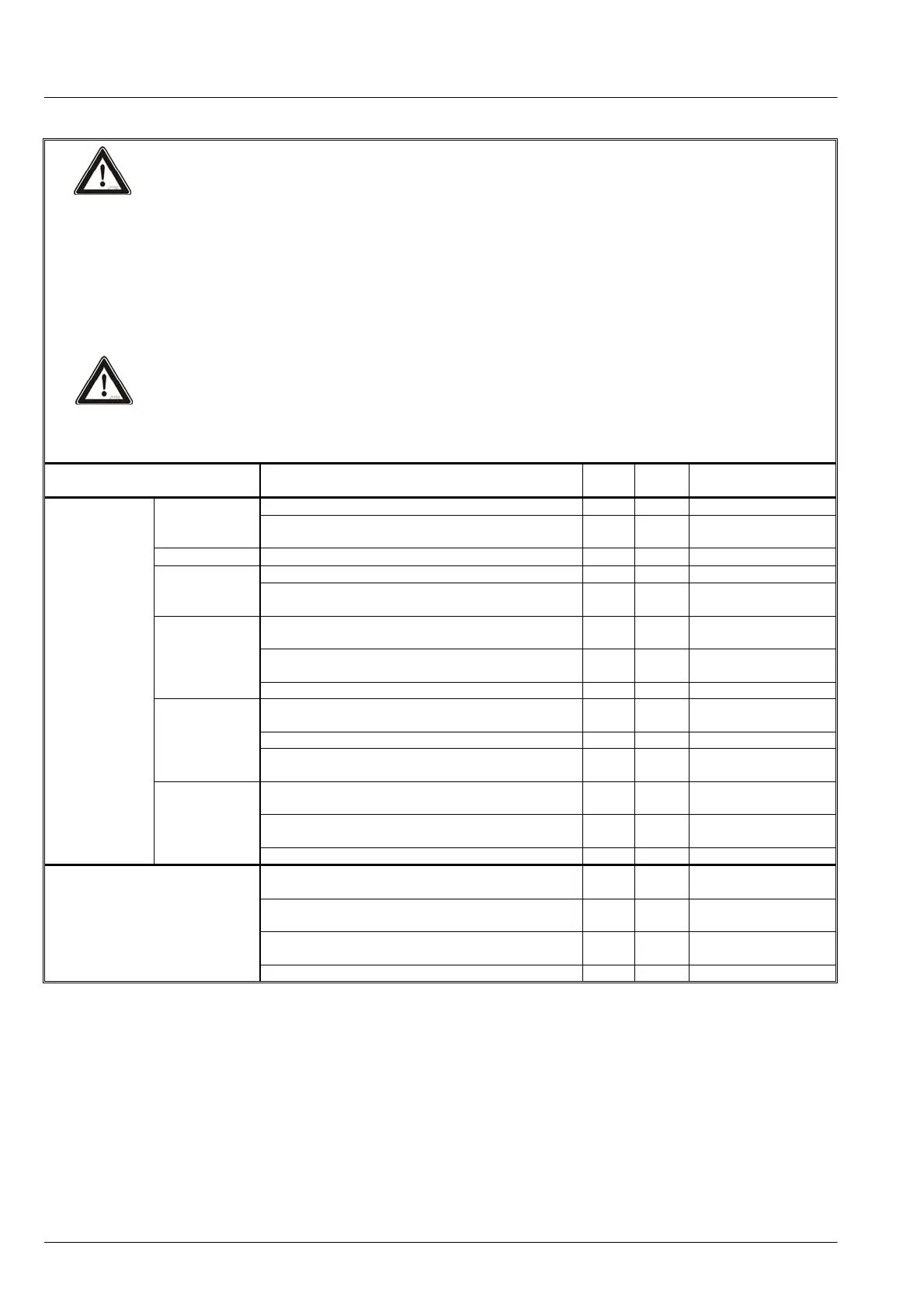

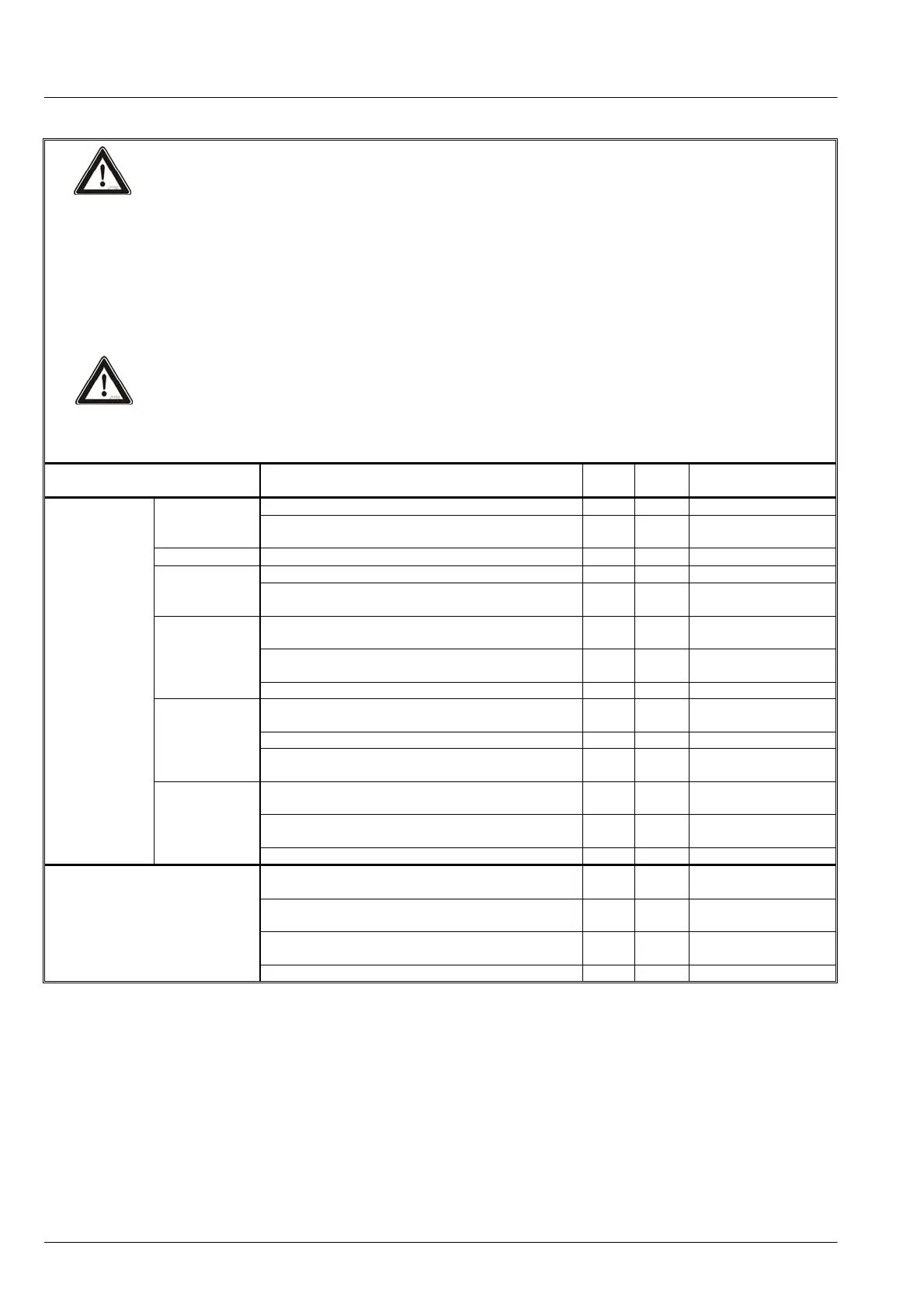

ELECTRIC SHOCK

The machine casing needs to be removed to carry out the subsequent work. It is possible that you

could come into contact with live parts. Such contact could be fatal!

Protect yourself from electric shock when carrying out work of this type by disconnecting the

appliance from the mains (by removing the fuses, pulling out the mains plug, etc).

For major testing and adjustment work it is essential that the machine has to be connected to the

mains and switched on while the casing is off. Such work must be undertaken only by trained and

authorised personnel.

Protect yourself from electric shock by taking appropriate measures, such as placing the ma-

chine in an insulated position, wearing voltage-protected gloves, and using appropriate tools

and test instruments.

BURNS AND SCALDING HAZARDS

Some components get very hot during operation, and are also under high pressure. The hot surfa-

ces can cause burns. The pressurised media (hot water, steam) can cause severe scalds if they sud-

denly and accidentally eject.

Never touch any component before you are quite sure that it is not hot.

Always depressurise the system before disconnecting any pipes and screw fittings by opening

the outlet valves and similar.

Check

Description Yes No Statement

Measure(s) to take

Leaked water on the framing floor

• Interior of

framing

Traces of water spray on the framing and other

components

• Brewing unit

(do not dismantle): Cracks on the housing,

Heat or burn marks on the pump, flowmeter

• Water

metering

system

Calcium residues or calcium fusions on pipes and

screw fittings

Calcium residues or calcium fusions on pipes and

screw fittings

Safety thermostat and heater connections: Heat

or burn marks

• Instant

heater

coffee/tea

Solenoid valves: oxidised connections

Heat or traces of burns on the plug or on the ca-

bles

State of the insulation.

• Booster

State of the booster brewing unit line: twisted or

bent?

Calcium residues or calcium fusions on pipes and

screw fittings

Safety thermostat and heater connections: Heat

or burn marks

Internal visual

check of

cleanliness

and mechani-

cal defects

Leaks and

effects of heat

• Steam

generator

Solenoid valves: oxidised connections

Ground conductor connections on housing and

EHS

Toroidal core transformer / stabiliser / PCBs: Heat

and burn marks, plug and cable defects

Cable loom /cabling: Insulation defects, burnt plug

casing or cable (odour!)

Electrical and electronic com-

ponents

Limit switch: oxidised connections,

Loading...

Loading...