Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 65

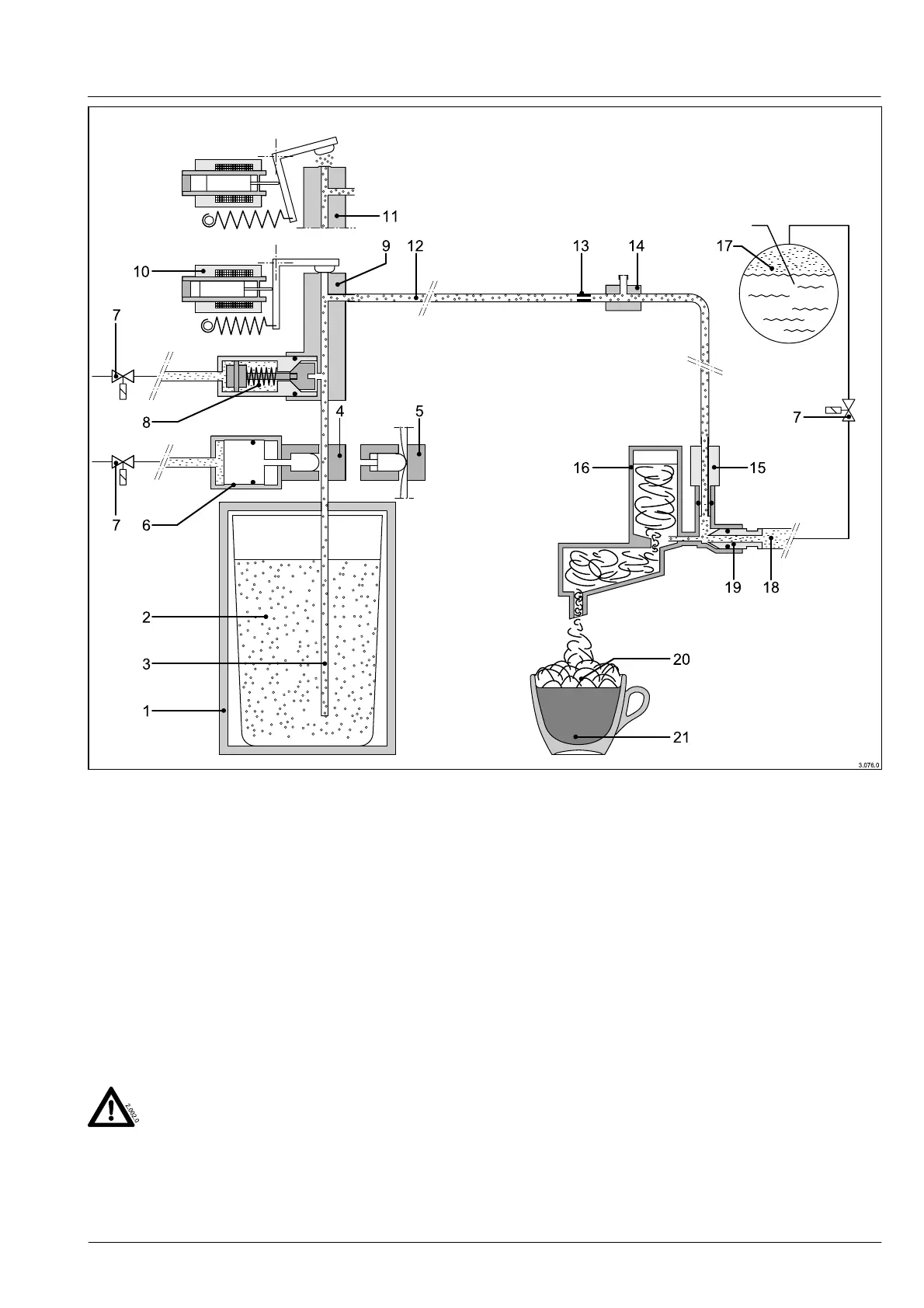

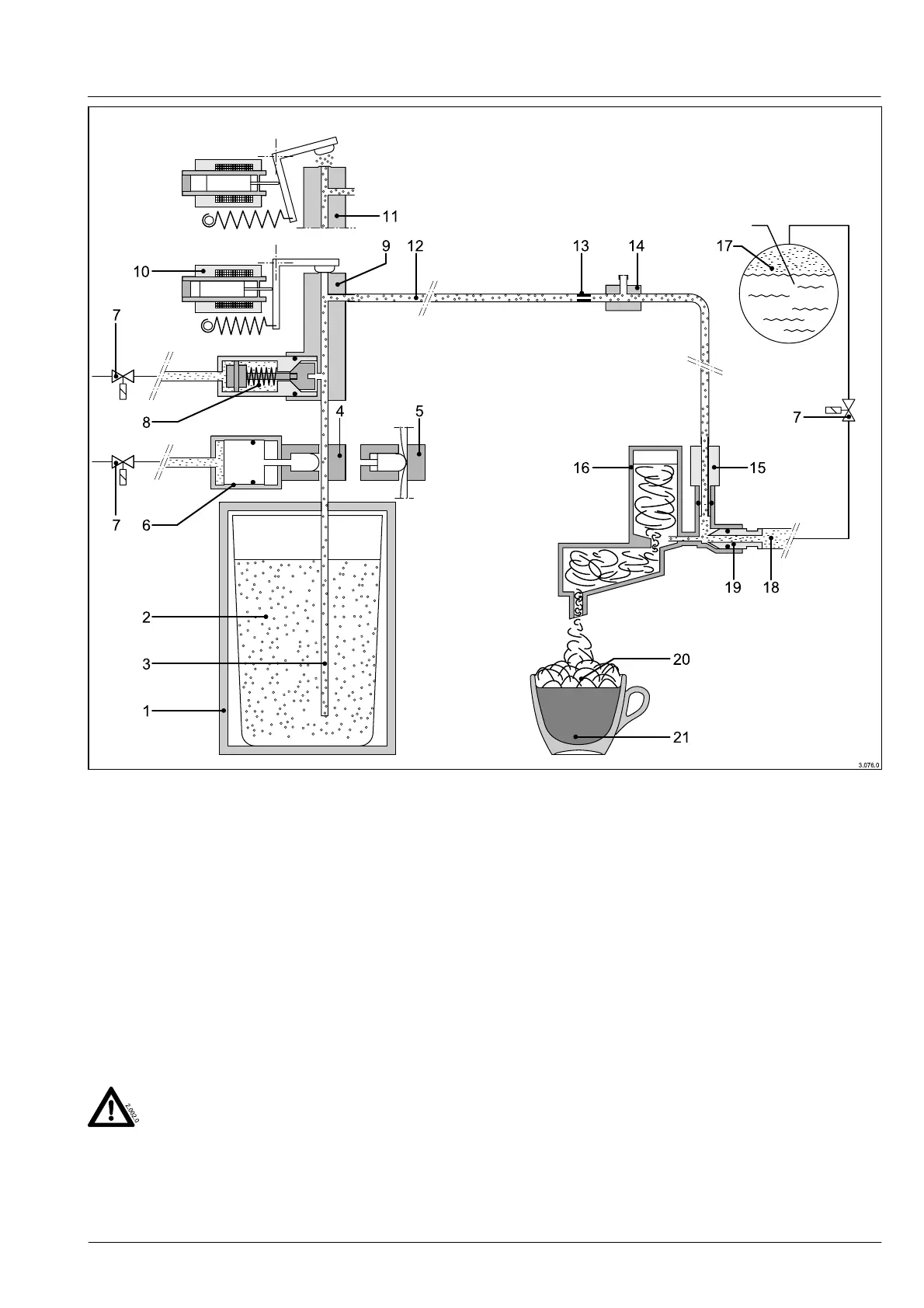

An illustration of the principle of preparing milk or milk foam.

The two systems are basically designed in the same way. For

foam preparation there is an additional aeration valve in the

refrigerator-foamer head connecting pipe.

1 Cooling area of the refrigerator

2 Milk / milk container

3 Suction tube

4 Squeeze housing

5 Suction line squeeze action

6 Water cylinder (squeeze cylinder)

7 Solenoid valve

8 Non-return valve

9 Ventilation valve

10 Dynamic coil magnet

11 Ventilation valve open

12 Milk pipe refrigerator to foamer head

13 Baffle

14 Air valve

15 Nipple

16 Foamer head

17 Steam generator

18 Steam pipe

19 Injector nozzle

20 Milk foam

21 Coffee (cappuccino)

Safety regulations for transporting, erecting and operat-

ing the refrigerator.

MATERIAL DAMAGE

The refrigerator cooling system functions

only when the appliance is standing upright.

In any other position the refrigerant may not

be drawn up by the compressor and the ap-

pliance could then be damaged.

For this reason the refrigerator must always be oper-

ated in an upright position.

During transport it must be laid down only on the

right hand side, and forwards (viewed from the front).

Having been transported in a tilted position, it must

be allowed to stand upright for at least six (6) hours

before it is allowed to operate (i.e. before it is

switched on).

The heat from the cooling unit must be vented off. If

cooling is insufficient the cooling efficiency inside

the cabinet reduces, and the cool ingredients are in-

sufficiently cooled.

Loading...

Loading...