Chapter 3 Functional descriptions

66 SMSO-2-02.03- 15.07.03

Make sure that sufficient air can circulate around the

cooler and clean the cooling ribs periodically.

Iced up evaporators reduce cooling efficiency and

consume more power. Defrost the appliance once the

layer of ice exceeds 3 mm in thickness. To defrost,

switch the appliance off (set the controller to zero).

Never use a sharp object, such as a knife, to remove

the layer of ice mechanically.

When no longer required, the refrigerator must be

disposed of in accordance with local waste disposal

regulations.

The start-up relay becomes warm when the motor

starts. It must be allowed to cool down before restart-

ing. For this reason do not switch the refrigerator on

and off at frequent intervals.

Pipe system

The processes for serving milk and milk foam differ from one

another. For this reason the entire milk pipe system and dos-

ing system from the milk container or from the steam valve to

the foamer head in the coffee outlet is designed as a dual

system. From the outside the systems are differentiated by the

colours of the tubes:

blue: milk

white: milk foam

Valve system

A special valve system ensures that on one hand no water

reaches the milk container while the pipe is being rinsed, and

on the other hand, that during the serving of the product the

pipes are fully siphoned out before they are rinsed. This re-

quires two valves: The pinch valve closes the suction pipe to

the milk container during the rinsing process. When the milk

serving has finished the ventilation valve opens the suction

pipe directly after the pinch valve. In this way the milk pipe to

the foamer head is always siphoned off completely before the

next product is served or before a rinse procedure. In this way

no milk is lost during the rinse procedure.

The pinch valve is activated with a (water) hydraulic cylinder,

the ventilation valve is driven electro-magnetically.

The solenoid valves for the rinse process and to control the

pinch valve cylinder are fitted to the rear of the refrigerator.

Rinse systems

For hygiene reasons the milk pipes are automatically rinsed

with water a certain time after the last milk serving. This is

intended to prevent colonies of bacteria from forming in the

pipe systems.

There are two different rinsing systems and the length of time

within which a rinse operation is carried out differs accord-

ingly.

Cold water rinse

This rinsing system was incorporated as standard until April

2002. Because only cold water is used to rinse, a brief pipe

rinse operation is carried out automatically approximately 2

minutes after the last milk serving.

Hot water rinse (hotflush)

This rinsing system has been incorporated as standard since

April 2002. Because the rinsing operation is much more effi-

cient, the time from the last milk serving until the automatic

rinse operation can be extended to up to 30 minutes. During

an operating period, if milk is served regularly, there is barely

a need to carry out the rinse operation, which reduces hot

water consumption and also machine availability.

Foamer head

The foamer head is the most important element in the produc-

tion of milk products. It acts simultaneously as the means of

conveyance for the milk, and as the element that heats and

foams the milk. The driving force here is the steam that flows

through one of the two pipes from the steam generator to the

foamer head, depending on the product selected.

It has a nozzle in each of the steam pipes in the foamer head,

which produces an under-pressure in its surrounding area as

the steam flows out, and thus sucks up milk from the milk

container in the refrigerator. The steam heats up this milk and

it flows through the outlet base of the foamer head into the

cup.

Hot milk / milk foam

The regulation process for the quantity of milk flowing to the

foamer head specifies whether hot milk or milk foam is pro-

duced. In principle the flow of milk is reduced in order to pro-

duce milk foam. There are two elements in the milk foam pipe

to regulate the flow of milk. On one hand it is a baffle, and on

the other an expander (ventilation valve), by means of which a

very precise measure of air is mixed into the milk pipe.

Level sensor (optional feature)

The level of milk in the refrigerator is monitored without con-

tact by means of an ultrasound level sensor.

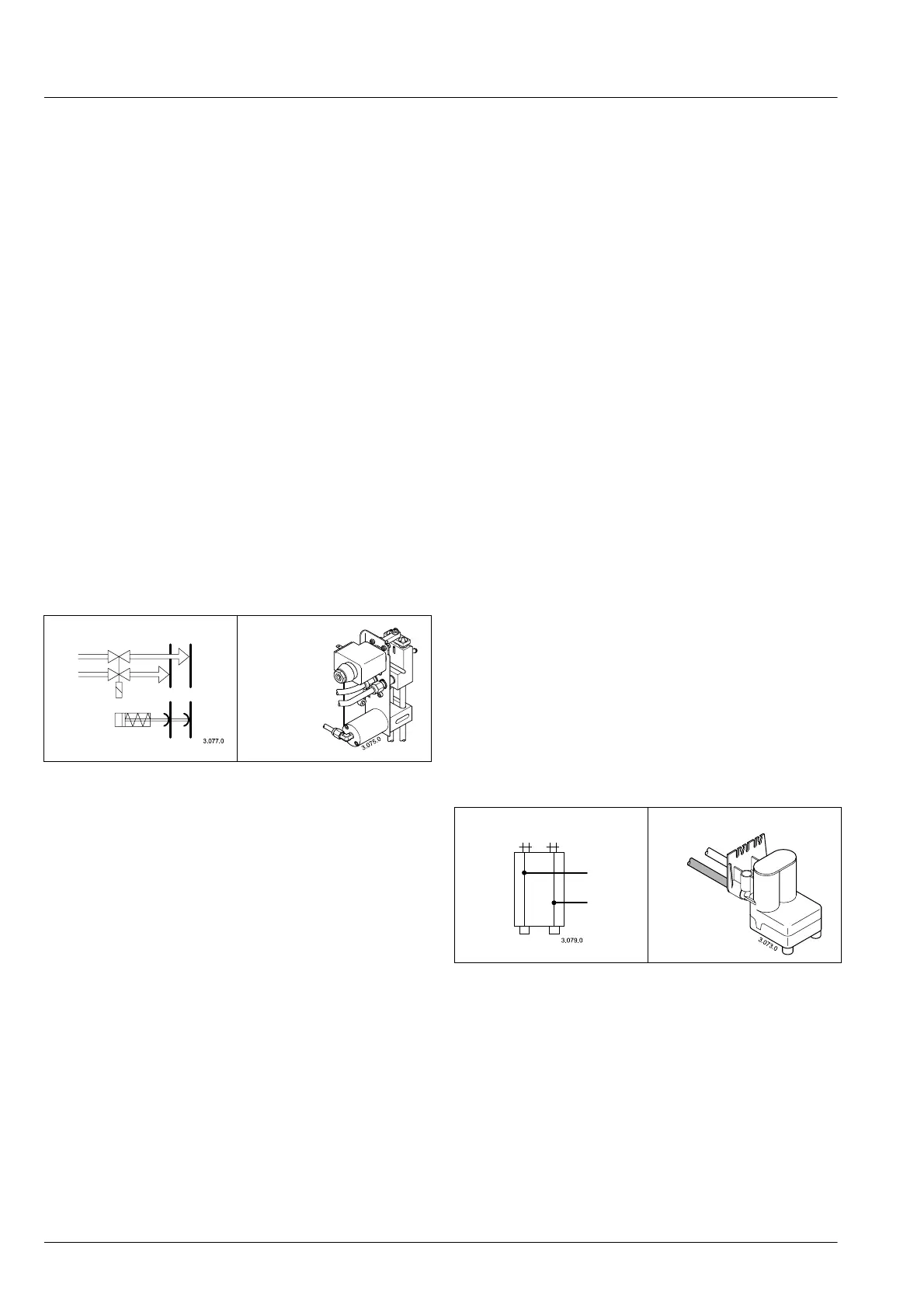

Drawing symbol

Illustration

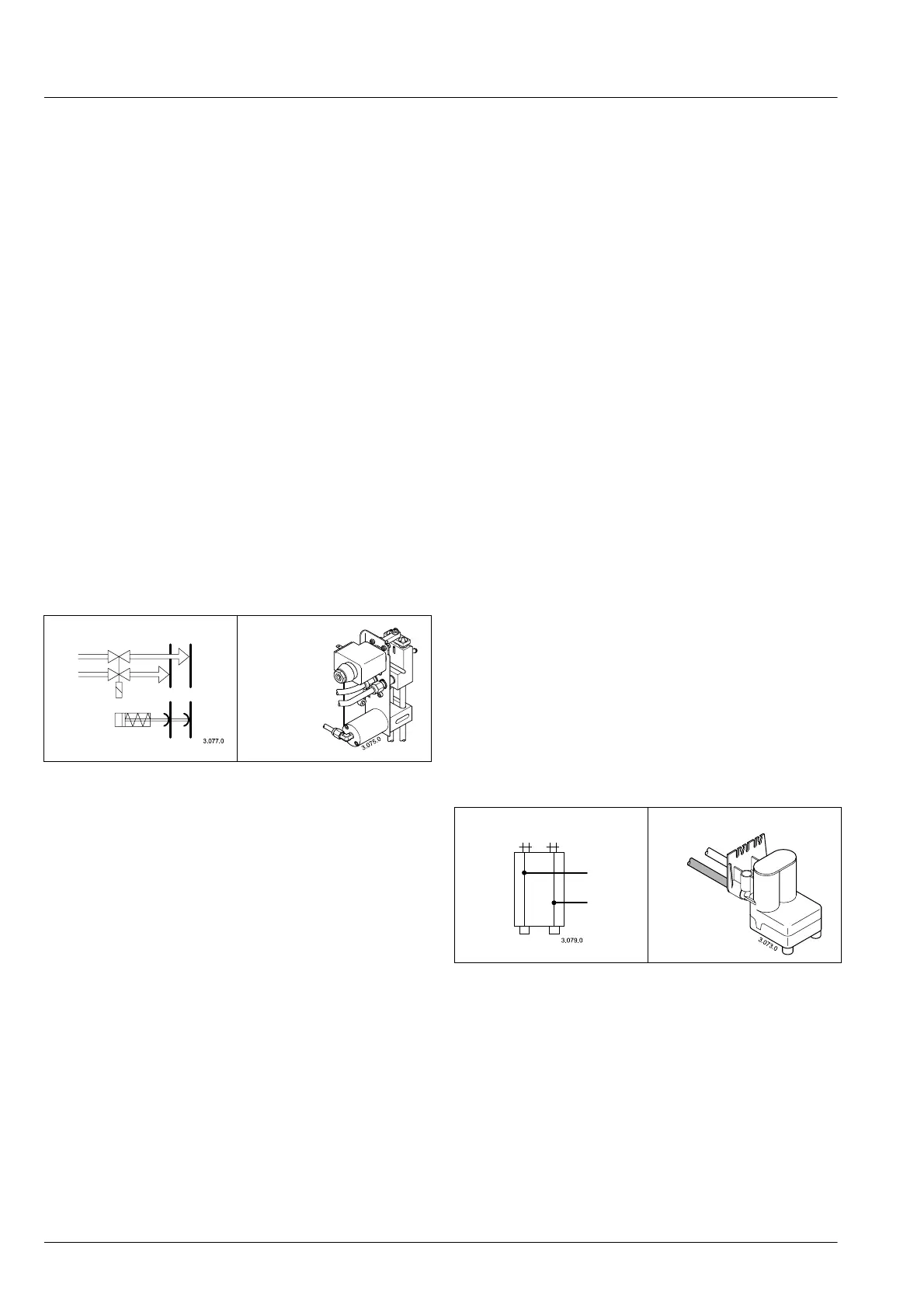

Drawing symbol

Illustration

Loading...

Loading...