5.19

5.2 DIAGNOSTIC TESTS

The function of these tests is to isolate faults at a lower level than major sub-assemblies.

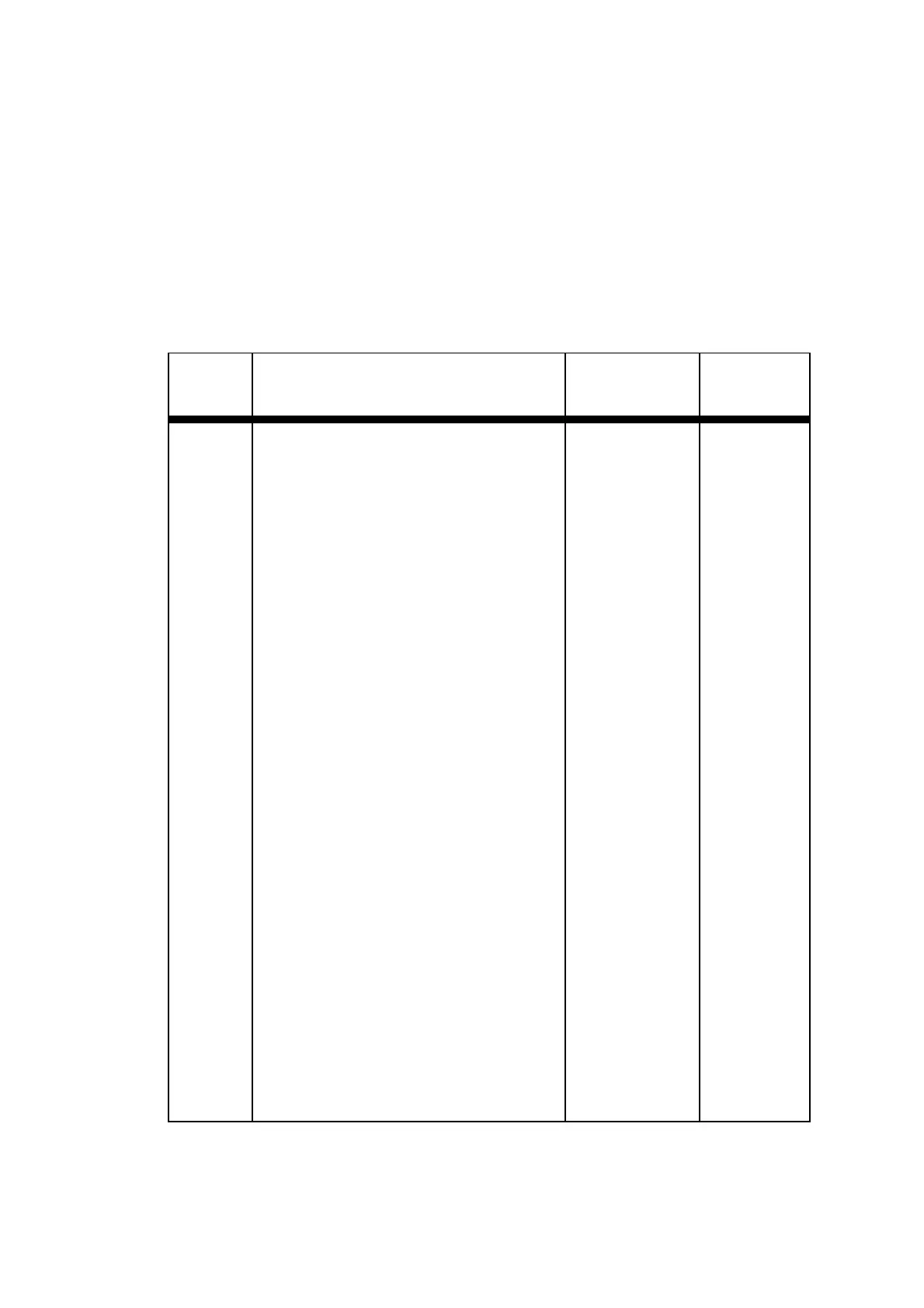

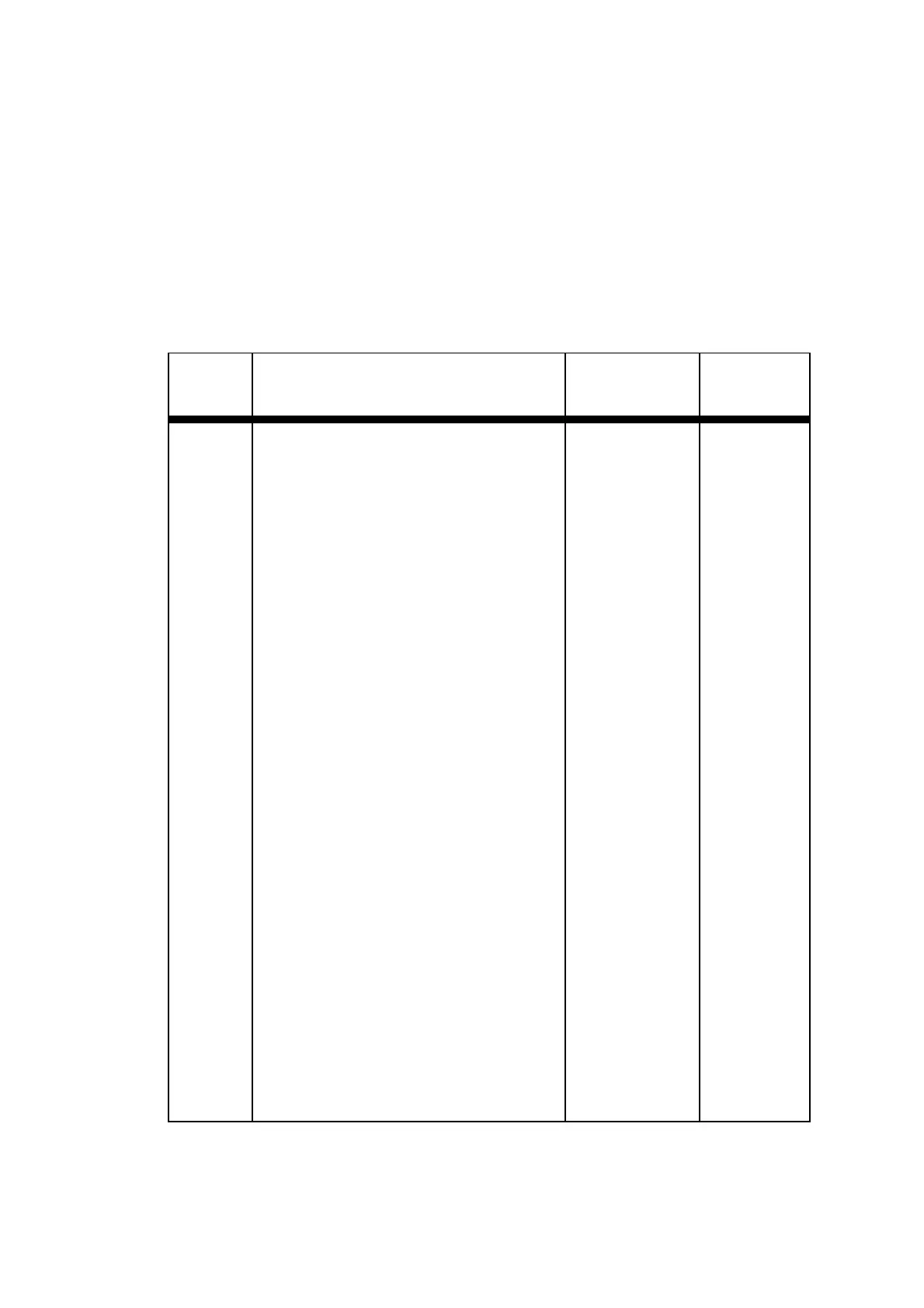

5.2.1 Oxygen Transducer

The following series of tests assumes that the transducer unit is connected to a close coupled

control/interface unit in which a 01100925B amplifier board is fitted. In systems in which the

transducer is separated from the control/interface unit, refer to circuit diagrams in Figures 2.9 or

2.10 (depending upon Transducer unit fitted) for connection details.

Step Procedure Normal

Indication

Corrective

Action

1

2

3

4

5

6

Remove LED wire from terminal

TB-D-5 on amplifier board.

Measure current from TB-D-5 to

TB-D-4.

Measure current in series TB-D-5

and wire removed from TB-D-5

Refit wire into TB-D-5

Pass nitrogen as a zero gas

through the transducer at a

sample flow rate of 100 to

200ml/min

Remove photo-electric cell wiring

at TB-D-1, 2 and 3, and measure

the output from the photo-electric

cells (Wire connected to TB-D-1 is

negative polarity). Adjust

mechanical zero (see Section 4.3)

to ensure that it is possible to

cause the reading to pass through

zero. Set to 0mV +/- 5mV

50mA+/-4mA

(70mA+/-3mA

upto Serial No.

925/546)

50mA+/-4mA

(70mA+/-3mA

upto Serial No.

925/546)

Replace

Amplifier

Board

01100925B

Replace

LED in

Transducer.

See Section

5.3.2.3.

Replace

photo-cell

LED, or,

oxygen

measuring

cell.

Loading...

Loading...