MX3500N SIMULATION 7 – 13

3-3

Purpose

Operation test/check

Function (Purpose)

Used to check the operation of the load in

the finisher and the control circuit.

Section

Finisher

Item

Operation

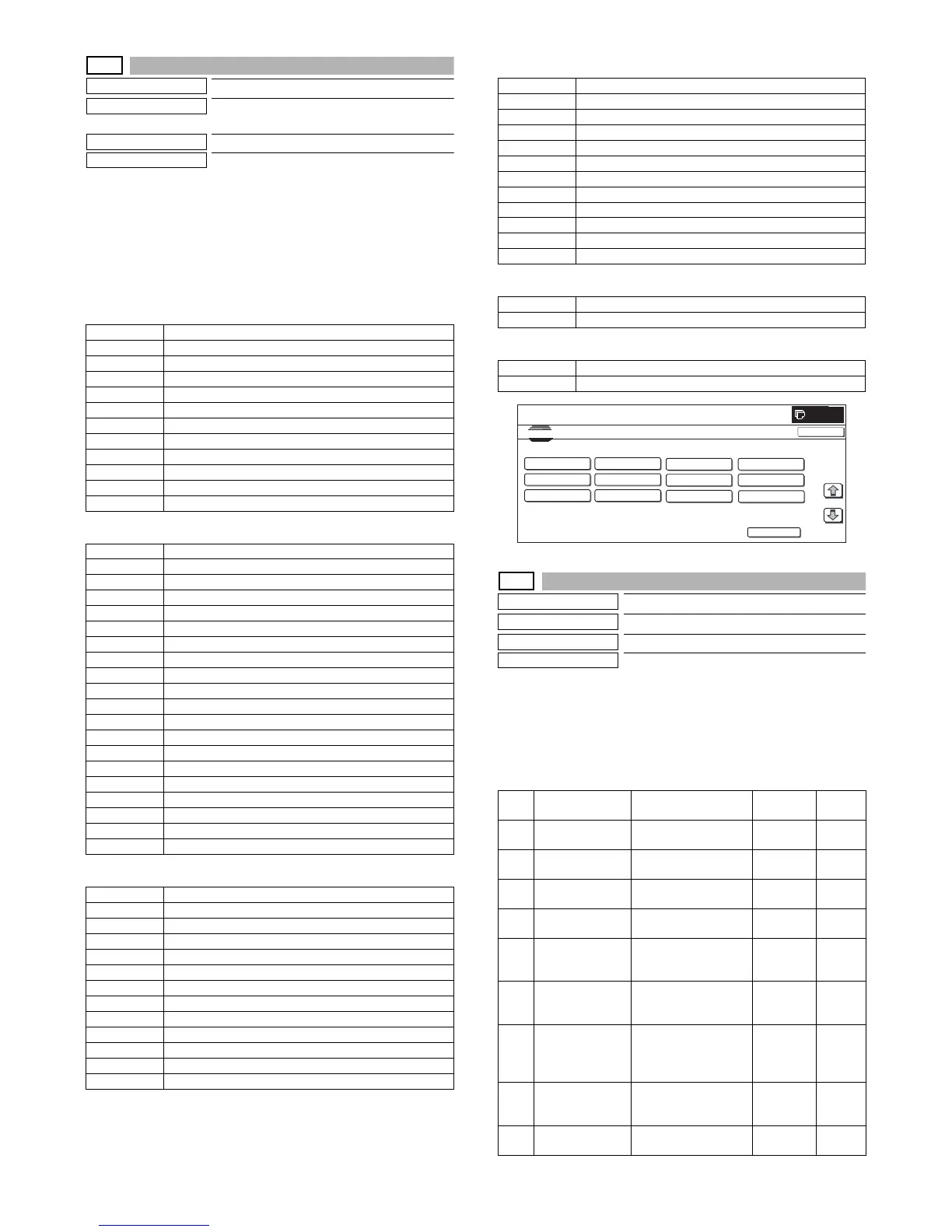

Operation/Procedure

1) Select the item to be checked with the buttons on the touch

panel.

2) Press [EXECUTE] button.

The selected load operation is performed.

When [EXECUTE] button is pressed, the operation is termi-

nated.

<When the 1K saddle finisher (MX-FNX2) is installed>

<When the 4K finisher is installed>

<When the inner finisher (MX-FNX1) is installed>

<When the 4K saddle finisher/saddle section>

<External punch unit (AR-PN1A/B/C/D)>

<Inner punch unit (MX-PNX1A/B/C/D)>

3-10

Purpose

Adjustment

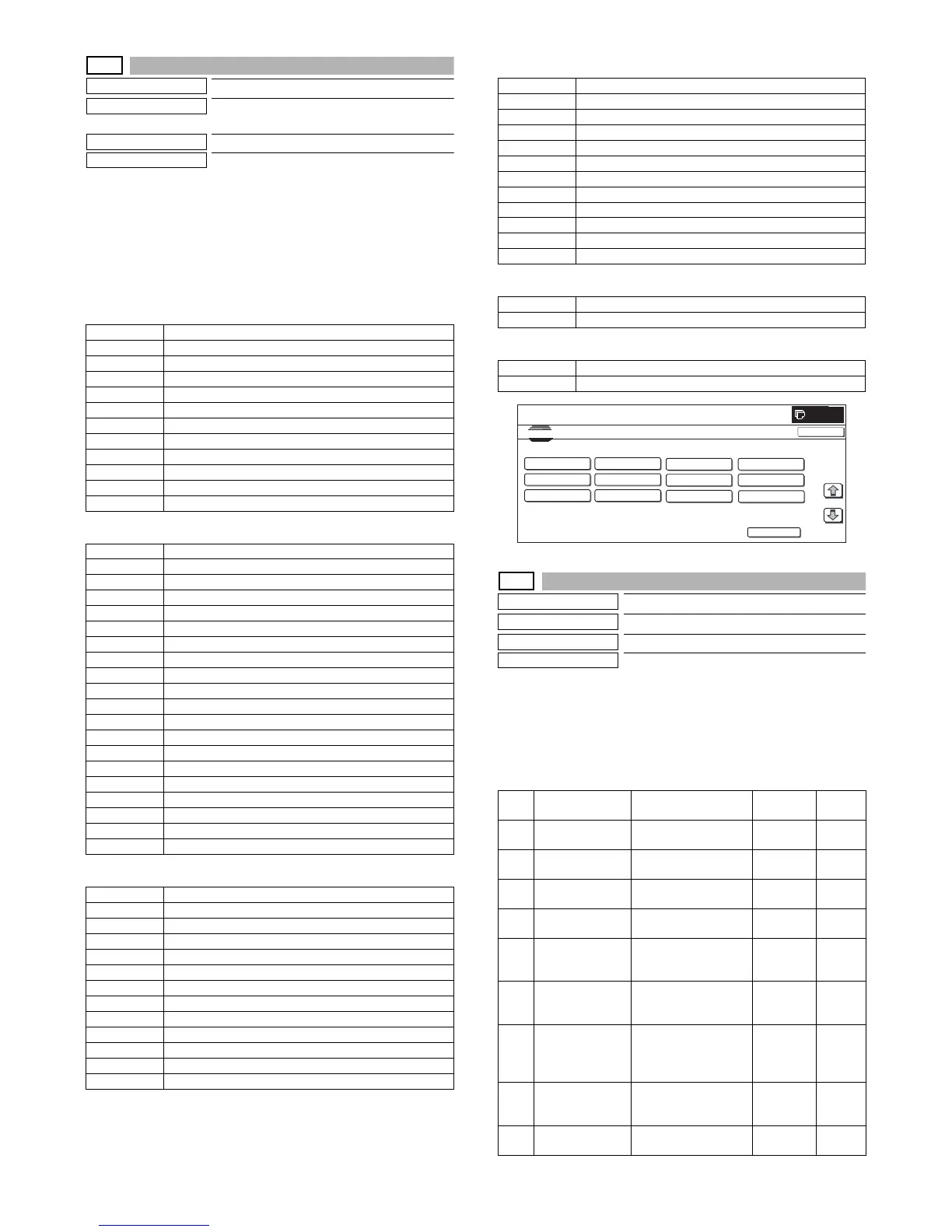

Function (Purpose)

Used to adjust the finisher.

Section

Finisher

Item

Operation

Operation/Procedure

1) Select the item according to the adjustment content with [↑] [↓]

buttons.

2) Enter the adjustment value with 10-key.

3) Press [OK] button. (The set value is saved.)

<Saddle finisher (MX-FNX2)>

FINRPS Entry port reverse path solenoid

FJPM Interface transport motor

FJFM Interface transport fan motor

FFM Transport motor

FPM Paddle motor

FAM Bundle paper exit motor

FFJM Alignment motor front

FRJM Alignment motor rear

FSM Staple shift motor

FFSM Staple motor

FLM Lift motor

FFC Folding clutch

FINRPS Entry port reverse path solenoid

FJPM Interface transport motor

FJFM Interface transport fan motor

FFM Entry port transport motor

FAM Bundle paper exit motor

FFJM Alignment motor front

FRJM Alignment motor rear

FSM Staple shift motor

FTLM1 Tray 1 lift motor

FTLM2 Tray 2 lift motor

FFSM Staple motor

FSWM Shift motor

FASM Rear edge assist motor

FPPM Paper positioning motor

FINRRS Inlet port roller separation solenoid

FBRRS Buffer roller separation solenoid

FFDRRS Paper exit roller separation solenoid

FBES Buffer rear edge holding solenoid

FSHC Shutter open/close clutch

FAORC Bundle exit lower roller clutch

FINRPS Entry port reverse path solenoid

FSLS Paper surface detection solenoid

FPDS Paddle solenoid

FBRS Belt separation solenoid

FRM Resist motor

FSWM Oscillation motor

FAM Bundle paper exit motor

FFJM Alignment motor front

FRJM Alignment motor rear

FSM Staple shift motor

FFSM Staple motor

FTLM Tray lift motor

FFANM Fan motor

FSIFM Saddle entry port transport motor

FSFM Saddle transport motor

FSFOM Paper folding motor

FSGM Guide motor

FSJM Saddle alignment motor

FSFSTM Stitch motor: Front

FSRSTM Stitch motor: Rear

FSLGM Paper holding motor

FSFS Saddle flapper solenoid

FS1DFS Paper deflection plate 1 solenoid

FS2DFS Paper deflection plate 2 solenoid

FSFCS Transport plate contact solenoid

FPNM Punch motor

FPSM Punch horizontal resist motor

FPNM Punch motor

FPSM Punch horizontal resist motor

Item Display Item Set range

Default

value

ASADDLE

POSITOIN

Saddle binding

position adjustment

0 to 400 200

BFOLDING

POSITION

Saddle folding

position adjustment

0 to 400 200

C FRONT ADJUST Alignment position

adjustment (front)

0 to 20 10

D REAR ADJUST Alignment position

adjustment (rear)

0 to 20 10

E STAPLE REAR Staple binding position

adjustment (one

position at the rear)

0 to 200 100

F STAPLE FRONT Staple binding position

adjustment (one

position in front)

0 to 200 100

G STAPLE BOTH Staple binding position

adjustment (two

positions at the

center)

0 to 200 100

H STAPLE PITCH Staple binding position

adjustment (two

positions in pitch)

0 to 100 50

I PUNCH

CENTER

Punch center

adjustment

47 to 53 50

0

SIMULATION

NO.03

03

TEST

FIN LOAD CHECK

EXECUTE

FINRPS

FJPM

FJFM

FFM

FPM

FAM

FFJM

FRJM

FSM

FFSM

FLM

FF

Loading...

Loading...