MX-M316N SIMULATION 6 – 25

25-2

Purpose

Setting

Function (Purpose)

Used to make the initial setting of toner

density when replacing developer. (Auto-

matic adjustment)

Section

Image process (Photoconductor/Develop-

ing)

Operation/Procedure

Toner cartridges must be installed to execute this setting (Toner

density control reference value setting)

Because of the structure of this machine, if SIM25-2 is executed

without the toner cartridges installed, the waste toner transport pipe

of the process UN may be locked.

1) Press [EXECUTE] key.

The developing motor rotates and the toner density sensor makes

sampling of the toner density, displaying the detected level.

After stopping the developing motor, it is set as the reference toner

density control level.

CAUTION: When the above operation is interrupted on the way, the

reference toner concentration level is not set. Also when

error code of EE-EL or EE-EU is displayed, the refer-

ence toner density level is not set normally.

CAUTION: Do not execute this simulation except when new devel-

oper is supplied. If it is executed in other cases, under-

toner or overtone may occur, causing a trouble.

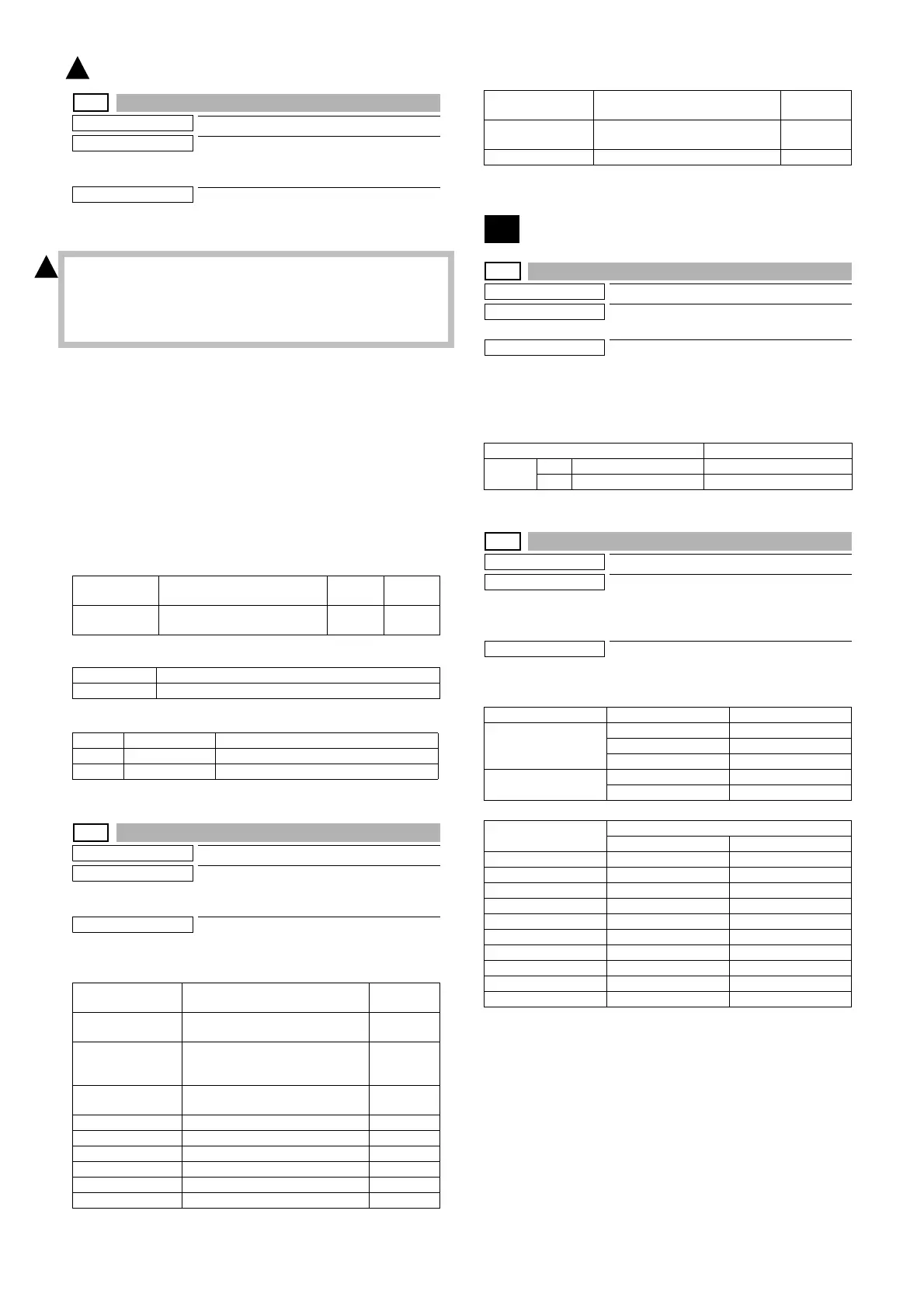

Display during execution of the simulation

Error content

25-4

Purpose

Adjustment/Setting/Operation data check

Function (Purpose)

Used to display the operation data of the

toner correction quantity. (Not used in the

market.)

Section

Process

Operation/Procedure

The operation data of the toner supply quantity are displayed.

26

26-1

Purpose

Setting

Function (Purpose)

Used to set Yes/No of installation of the Job

separator.

Section

Paper exit

Operation/Procedure

1) Enter the set value with 10-key.

2) Press [OK] key. (The set value is saved.)

This setting is required to use the Job separator.

26-2

Purpose

Setting

Function (Purpose)

Used to set the paper size of the paper feed

tray. (When the paper size is changed, this

simulation must be executed to change the

paper size in software.)

Section

Paper feed

Operation/Procedure

Select a paper size and a weight system to be changed.

Item/Display Content

Display

range

Default

value

AT DEVE ADJ Automatic development

adjustment value

1 - 255 128

Item/Display Content

TCS Toner sensor output value

Display Error name Error content

EE-EL EL abnormality Sensor output level less than 78

EE-EU EU abnormality Sensor output level over 178

Item/Display Content

Display

range

TONER DEN_LT Current toner density sensor output

value (final value)

1 - 255

TONER DEN_ST Current toner density reference

value display (the value including all

the correction values)

1 - 255

AUTO DEVE Automatic development adjustment

value

1 - 255

ALL All correction reference value 1 - 255

LIFE Life correction value -128 - 127

ENV Environment correction value -128 - 127

DUPLEX Duplex correction value -128 - 127

PRINT RATE Print ratio correction value -128 - 127

AREA Area correction value -128 - 127

AUTO DEVE AREA Area in the auto development

adjustment

-128 - 127

CURRENT AREA Current area -128 - 127

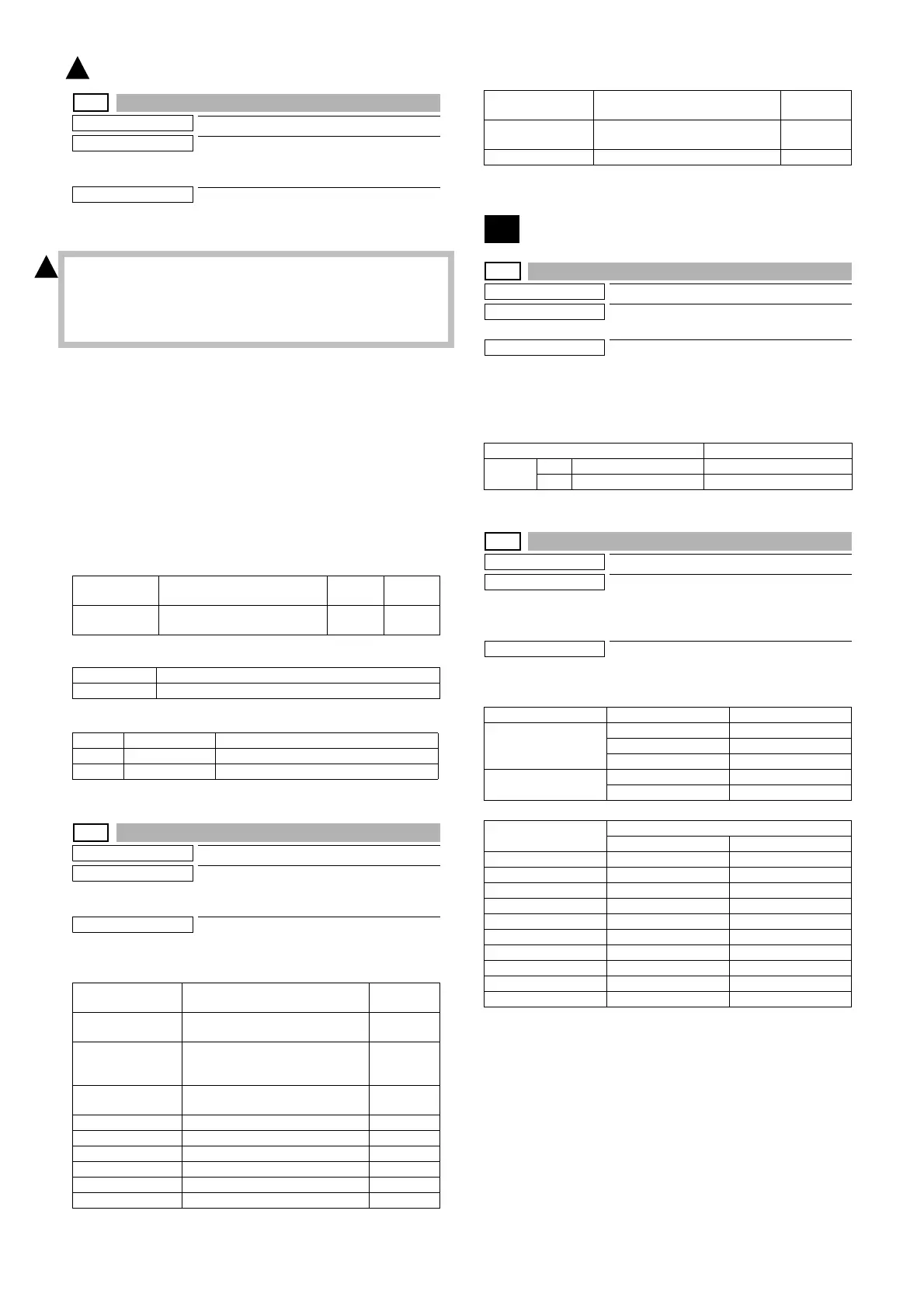

Item/Display Content

A 0 YES Job separator provided

1 NO Job separator not provided

Item Setting value Content

LEGAL SET 0 8.5 x 14

1 8.5 x 13.4

2 8.5 x 13.5

G/LBS SET 0 GRAM

1LBS

Destination

Setting value

LEGAL SET G/LBS SET

U.S.A 8.5 x 14 LBS

CANADA 8.5 x 14 LBS

INCH 8.5 x 14 LBS

JAPAN 8.5 x 14 GRAM

AB_B 8.5 x 14 GRAM

EUROPE 8.5 x 14 GRAM

U.K. 8.5 x 14 GRAM

AUS. 8.5 x 14 GRAM

AB_A 8.5 x 14 GRAM

CHINA 8.5 x 14 GRAM

Item/Display Content

Display

range

1

: ‘15/Aug.

1

Loading...

Loading...