GM35 Operating Instructions

Probe Model

Planning guidelines

20 © SICK MAIHAK GmbH • Germany · All rights reserved 8009389/07-2006

3.2 Project planning checklist

Step-by-step planning

The following checklist is intended to help you carry out and check the necessary planning

activities on a step-by-step basis before the system is commissioned. For technical specifi-

cations and dimension drawings of the system components, see page 99 and the following

Chapter.

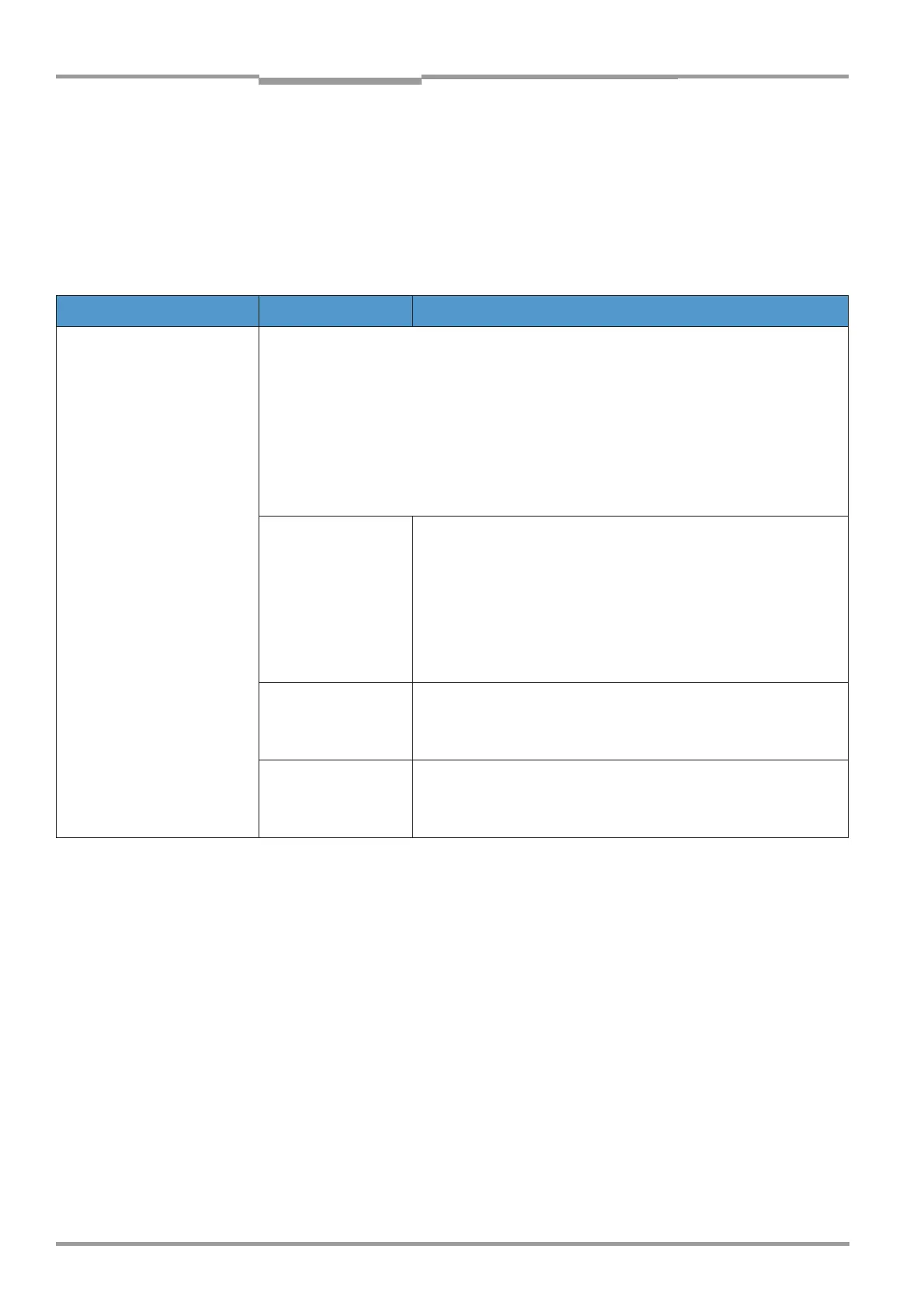

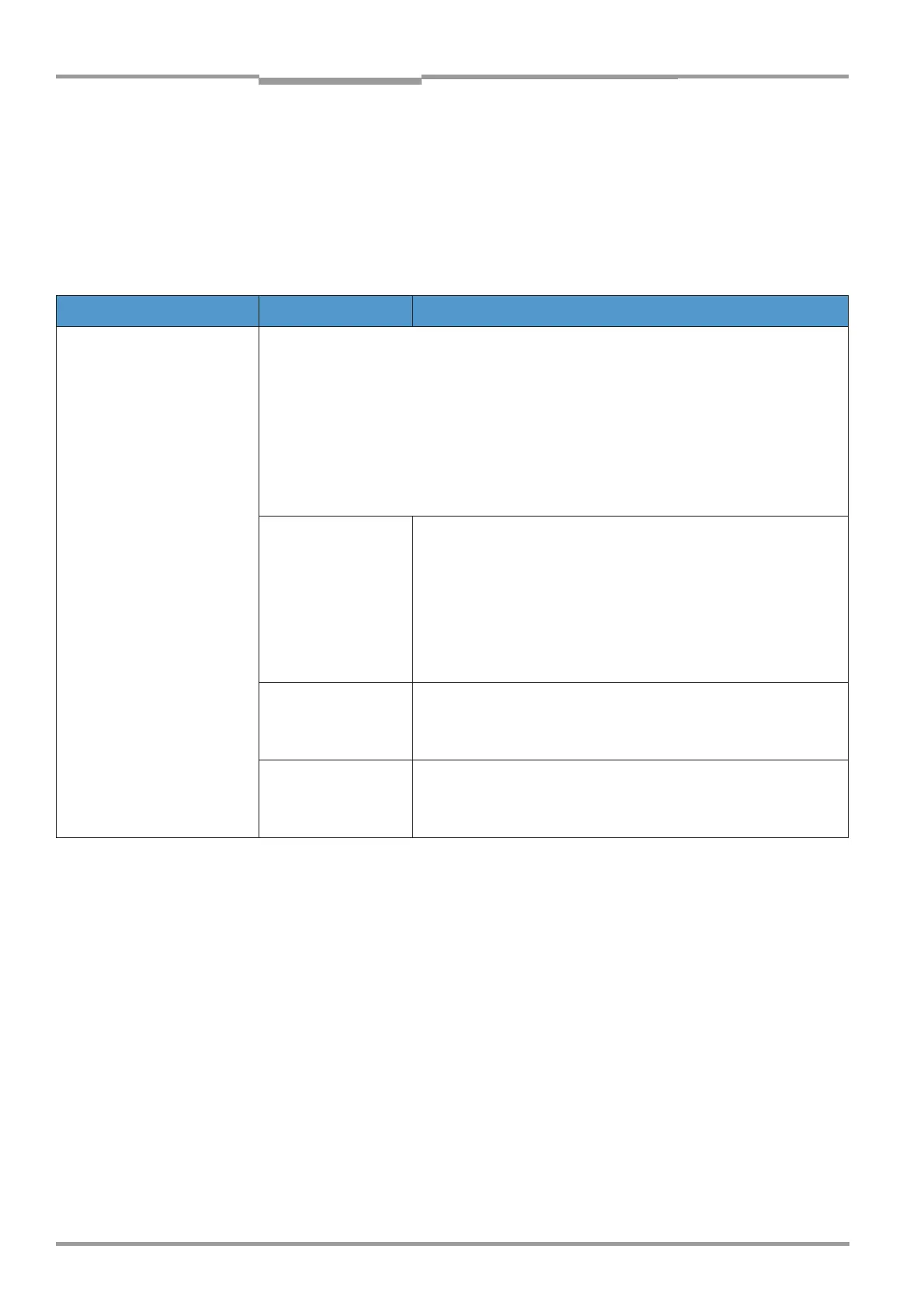

Topic Task Measures/considerations

Determine the measuring

point

Observe any country-specific

legal stipulations (e.g. VDI

3950).

■ Ensure that the inlet and outlet sections are unimpeded.

✓ round duct cross-Chapter: 3x duct diameter

✓ rectangular cross-Chapter:

hydraulic diameter

✓ If these specifications cannot be met: inlet Chapter> outlet Chapter,

e.g.

2

/

3

:

1

/

3

; concentration distribution should be as homogeneous as possible.

■ Emissions

measuring point

✓ Obtain official approval for emissions measuring point.

✓ Calibration apertures should be provided at a point that is easily

accessible

✓ Take measures to avoid cross-interference between the GM35

and the calibration probe. The calibration gland should be

located at a minimum distance of 0.5 m (1.6 ft) upstream of the

measuring device.

■ Operating

conditions

✓ Observe the technical specifications for the duct and ambient

conditions.

✓ Gast temperature above/below dew point (dry/wet)

■ Pressure

at the measuring

point

✓ A mounting location with underpressure in the duct is ideal.

✓ For duct pressures > 10 hPa (0.15 psi), please contact SICK

MAIHAK to select the correct purge air fan type.

D

4F (cross-section)

U (circumference)

----------------------------------------------=

Loading...

Loading...