tables should be used. Depending on which nominal diameter has been set at the pipe part,

COMOS reads the actual dimension values from the table and writes them to the pipe part:

1.

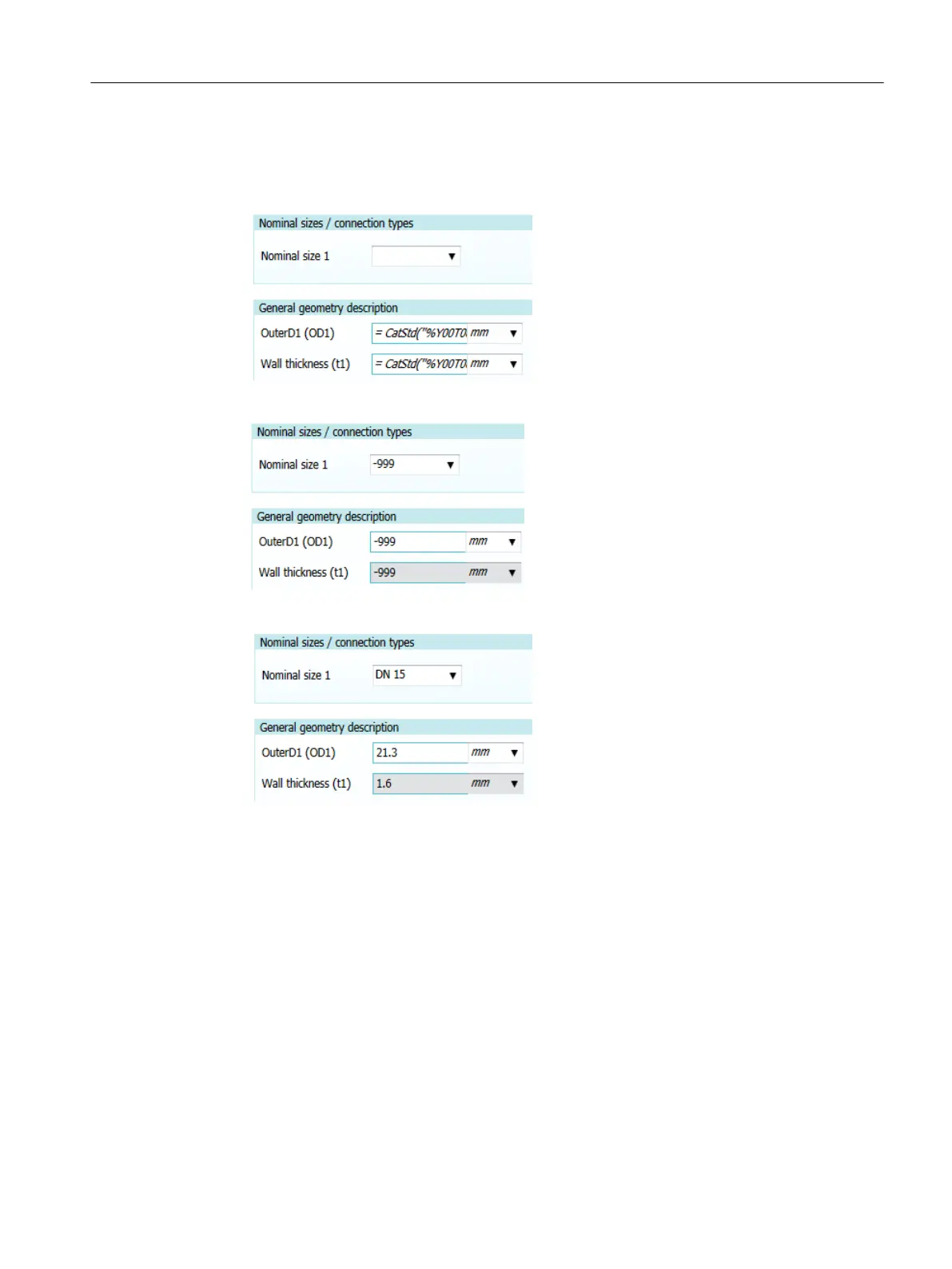

Geometry attributes at the base object:

2. Geometry attributes at the engineering object before the nominal diameter is set:

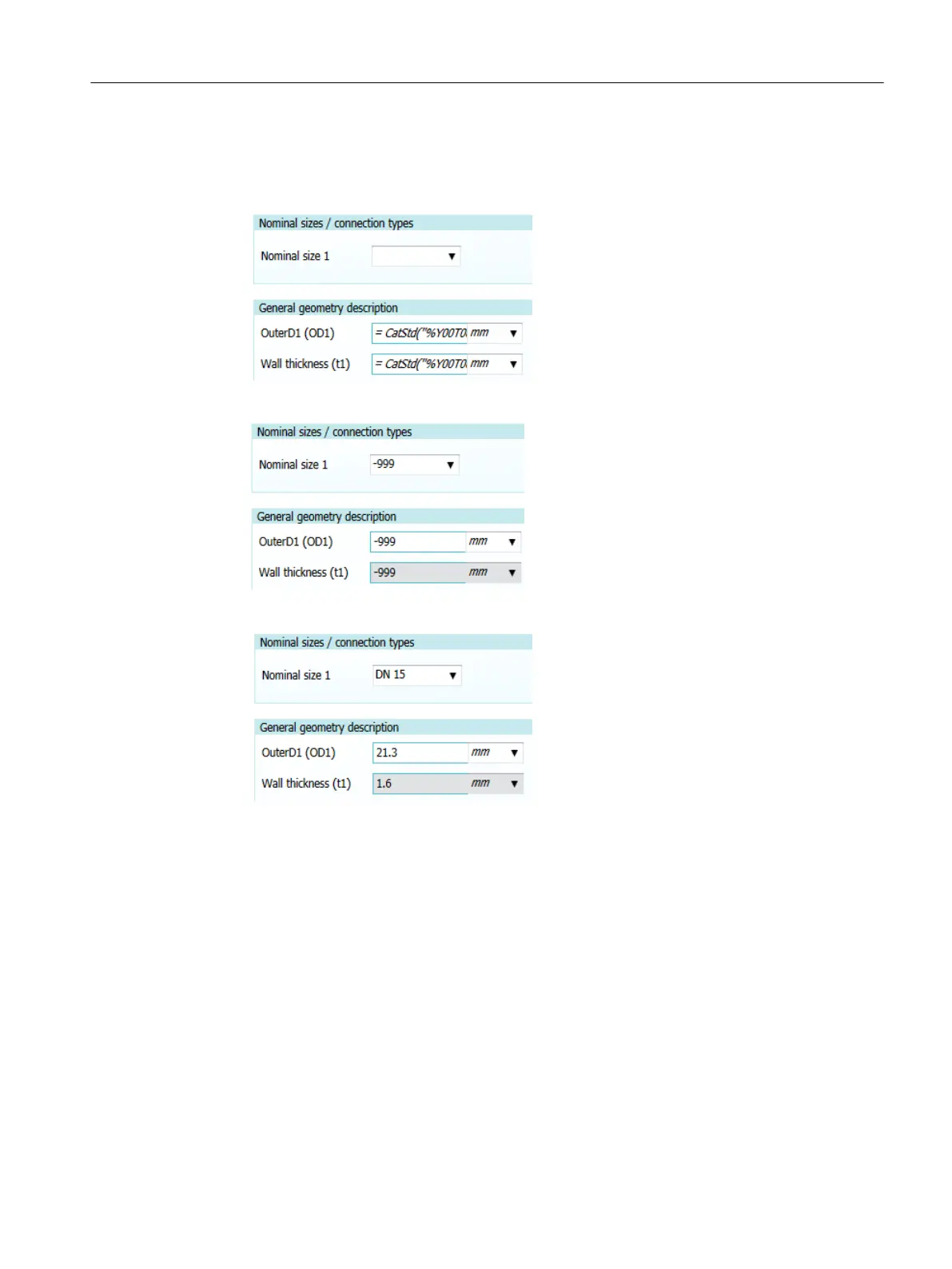

3. Geometry attributes at the engineering object after the nominal diameter is set:

Possible sources for dimensions

Depending

on the calculation formula that was entered, the dimensions are taken from one of

the following sources:

● Standard geometry tables

● Pipe part:

– The dimension comes from the local dimensions.

– The value of a different attribute is applied to the dimension.

– The dimension is calculated from different attribute values.

● Pipe part element

Preparing for creation and maintenance of pipe specs

3.5 Administering pipe part catalogs

PipeSpec Designer

Operating Manual, 09/2014, A5E32076948-AA 29

Loading...

Loading...