Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 2

C74

C74

Section 2

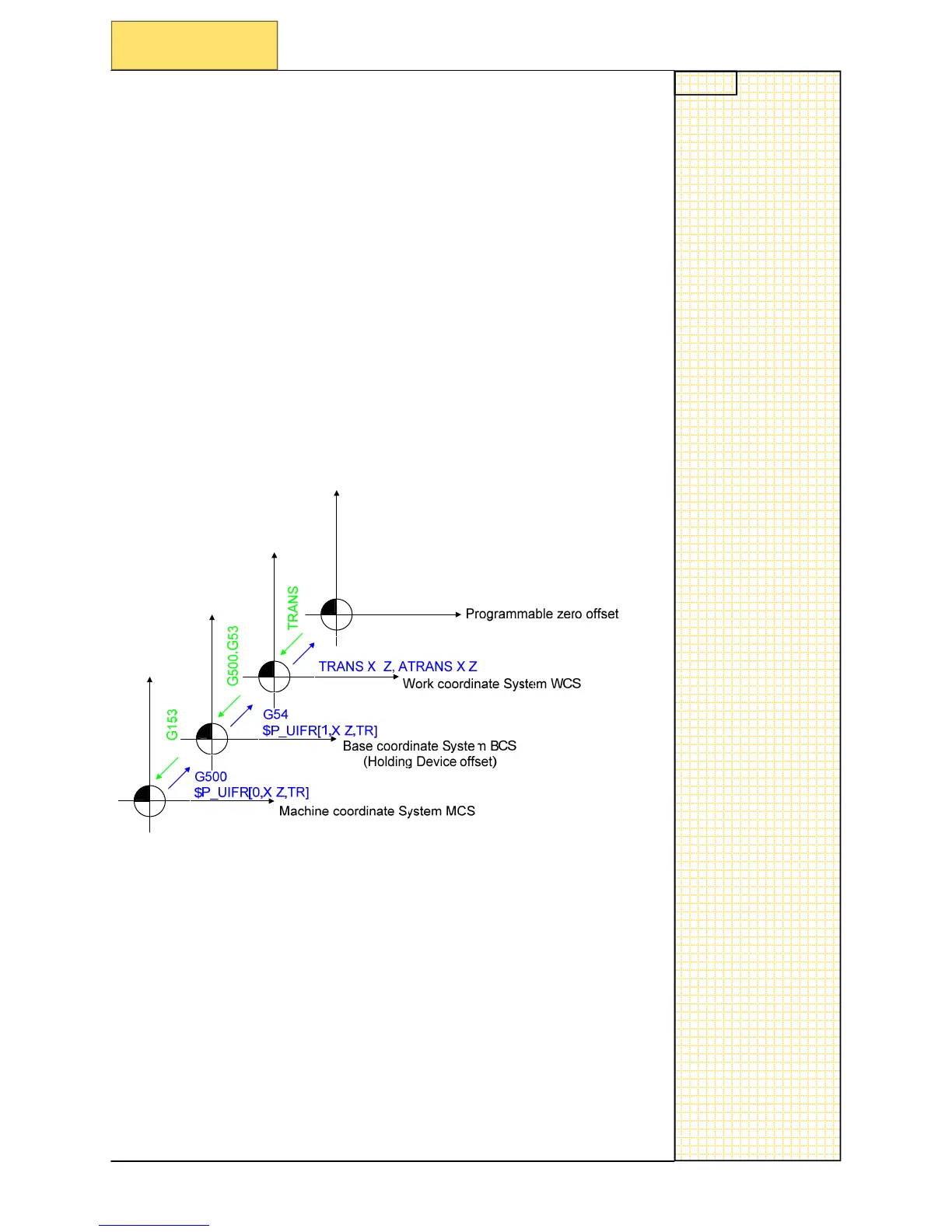

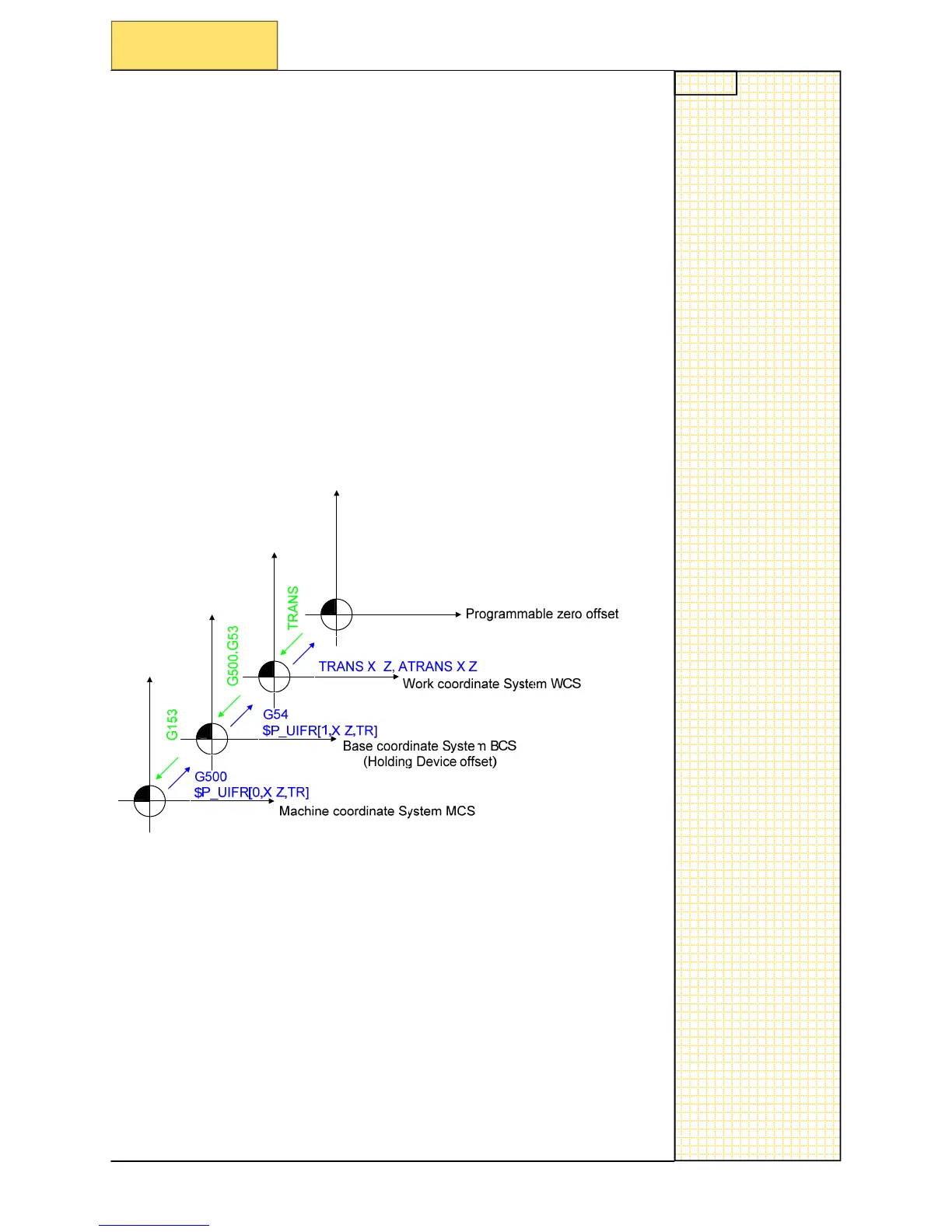

Overview of the coordinate system

The following diagram gives an overview of the offset possibilities of the

control:

Machine Coordinate Sy

stem (MCS):

The machine coordinate

system is determined by the manufacturerer of

the machine, the zero value is deter

mined at the 1st setup by the machine

tool builder

and should only be changed by experienced service personnel.

The G code G153 can be used blockwise to per

form a move in the MCS at

any time in the program.

NOTE: The

instruction G153 is only blockwise active

!

Description

of the single components:

Description of the zero offset:

The zero offset determines the difference between the Machine Coordina-

te System (MCS) and t

he Workpi

ece Coordinate System (WCS).

For programming, the dimensions are with reference to the

Workpiece

Coordinate System.

The exact position of th

e workpiece on the machine is not known at the

time of writing the workpiece progra

m.

The distance between the machine zero point and the workpiece zero

point must therefore be obtained.

This geometric difference is known a

s the zero offset.

2.1 Overview of the coordinate system

Loading...

Loading...