Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 3

C74

C74

Section 2

Basic Coordinate System (BCS):

The Basic C

oordinate System works between the Machine Coordinate

System and

the Workpiece Coodinate System. If the value of the Basic

Coordinate System is changed, the

n the Workpiece Coordinate System

will move respectively.

The Basic C

oordinate System is activated with G500. When G500 is pro-

grammed th

e modally active (G54) will be deactivated.

With G54 active a move

ment can be programmed with respect to the BCS

by using the blockwise

G code G53.

Wokpiece Coordinate Sy

stem (WCS):

The workpiece coordinat

e system is the offset between the BCS and the

origin of the

component.

When the BCS system

has no value, then the WCS is the offset to the

MCS s

ystem.

7 Zero offse

ts are therefore available to the operator/programmer.

G500 - Basic Zero Offset

G54 - 1st. Zero Offset

G55 - 2nd. Zero Offset

G56 - 3rd. Zero Offset

G57 - 4th. Zero Offset

G58 - 5th. Zero Offset

G59 - 6th. Zero Offset

Example:

Programme

d

G0 G153 X0

Y0 Z0

Typically the following po

sition will be reached, dependant upon the machi-

ne builder.

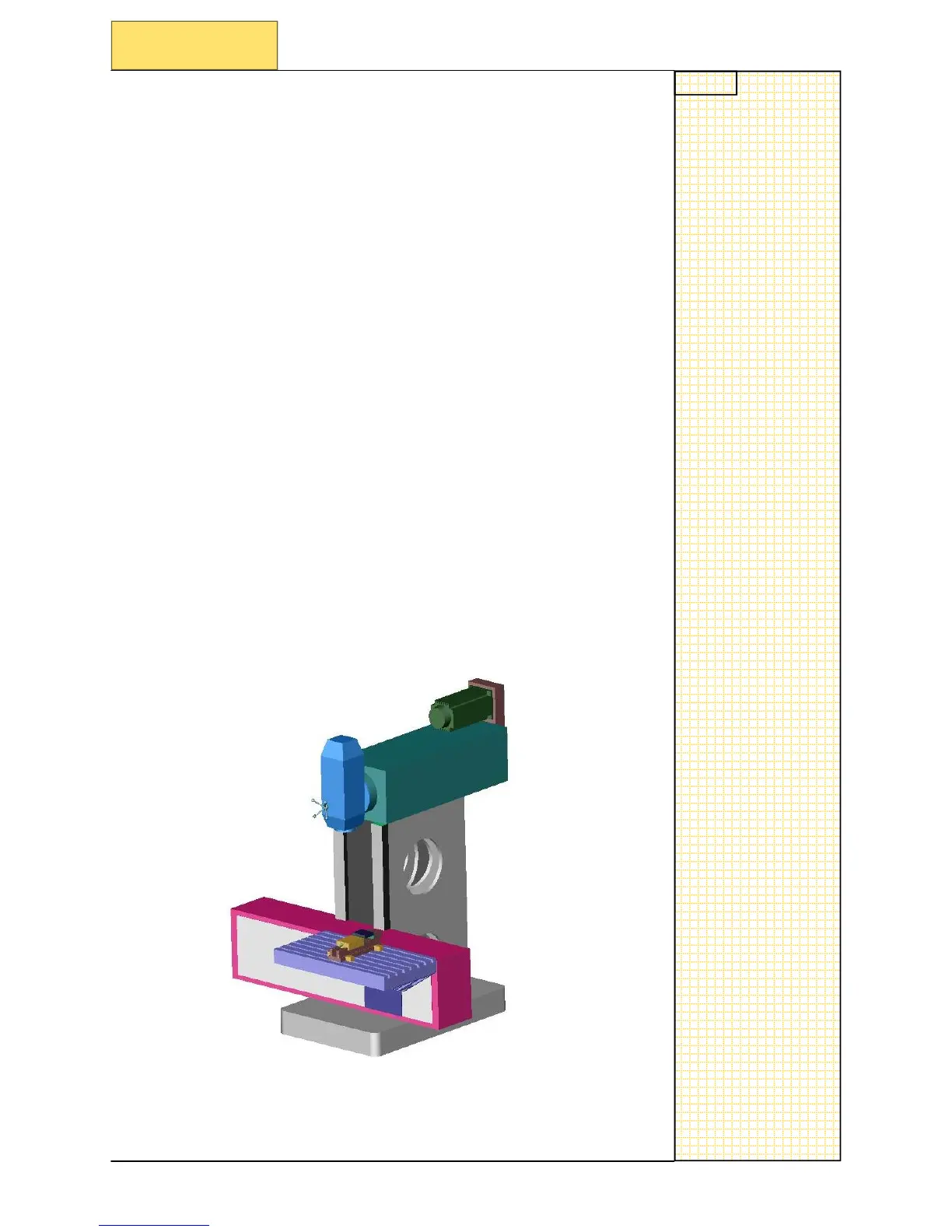

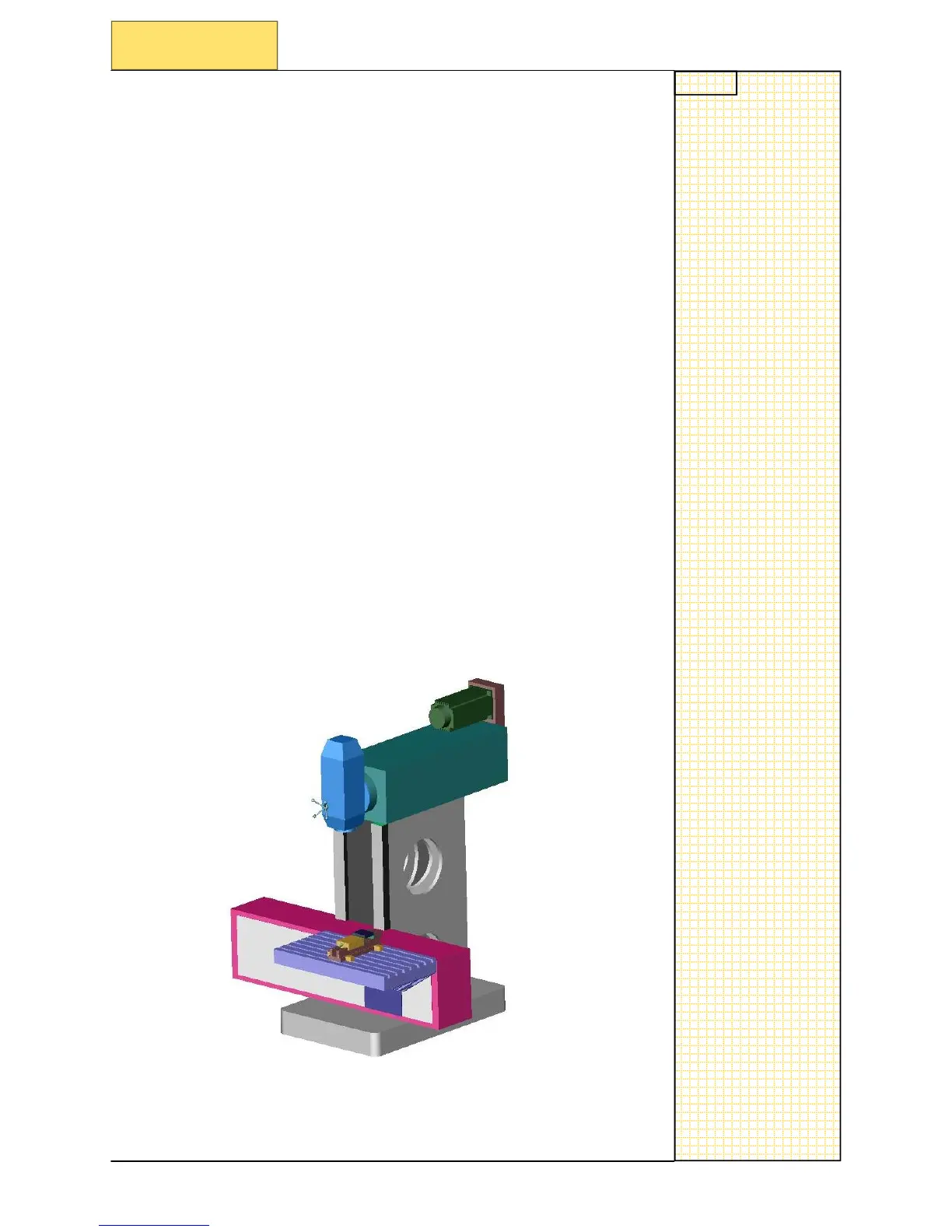

Overview of the coordinate system

Loading...

Loading...