cles in STOCK REMOVAL mode

5

© Siemens AG, 2002. All rights reserved

5-102 SINUMERIK 840D/810D Operator's Guide ManualTurn (BAM) – 08.02 Edition

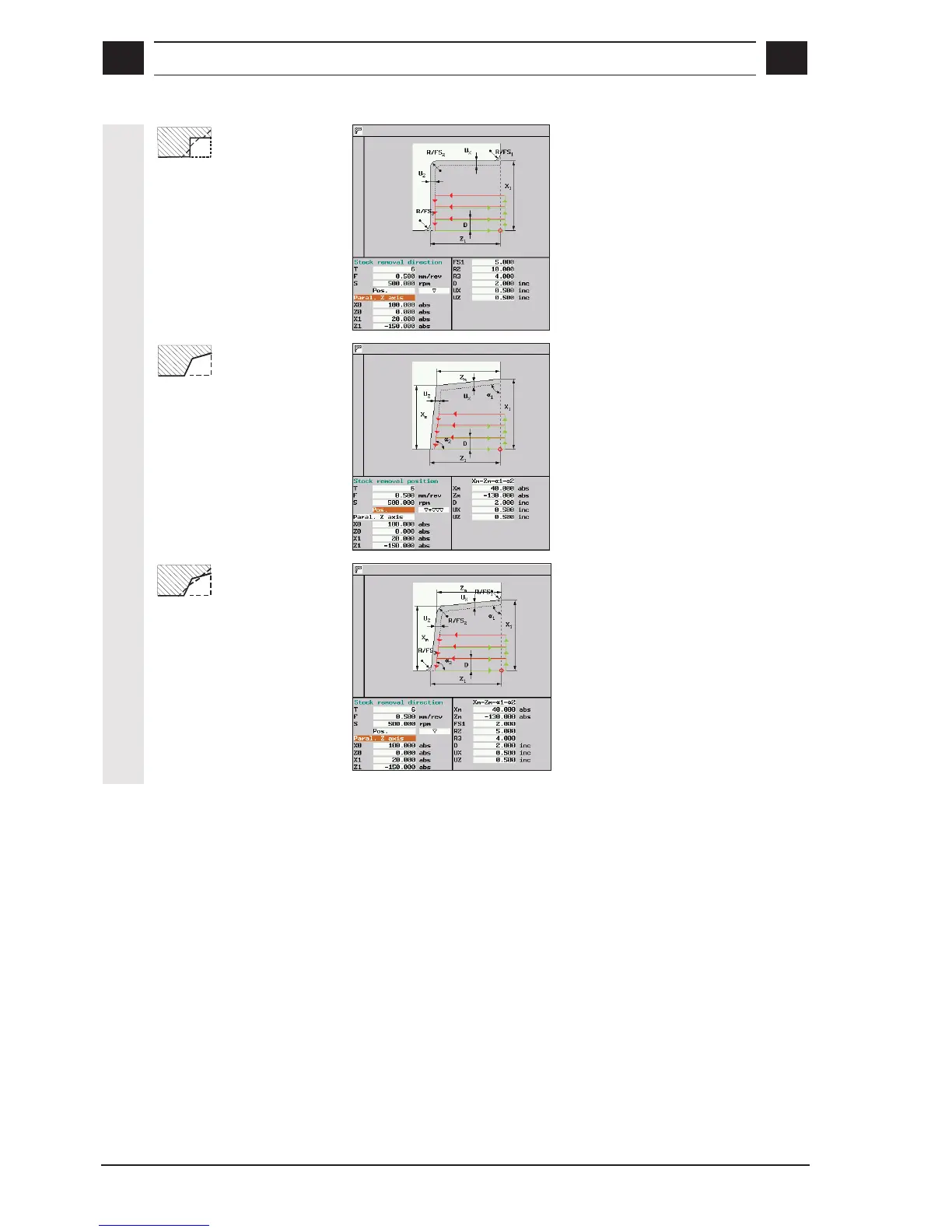

Stock removal cycle straight with

radii and chamfers

Stock removal cycle with conicals

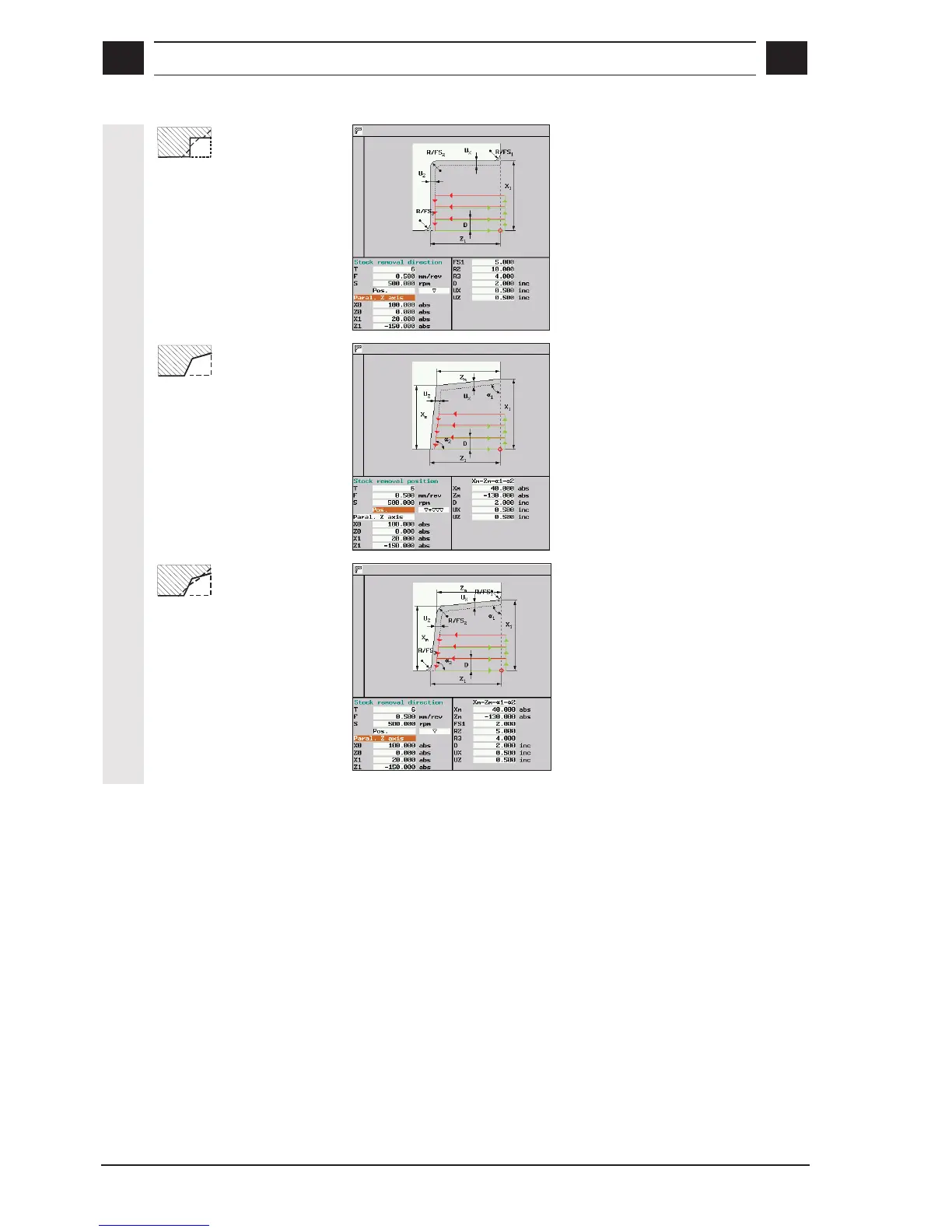

Stock removal cycle with conicals,

radii and chamfers

Loading...

Loading...