cles in STOCK REMOVAL mode

5

© Siemens AG, 2002. All rights reserved

5-108 SINUMERIK 840D/810D Operator's Guide ManualTurn (BAM) – 08.02 Edition

If the groove is wider than the active tool, then the width is cut in

several steps.

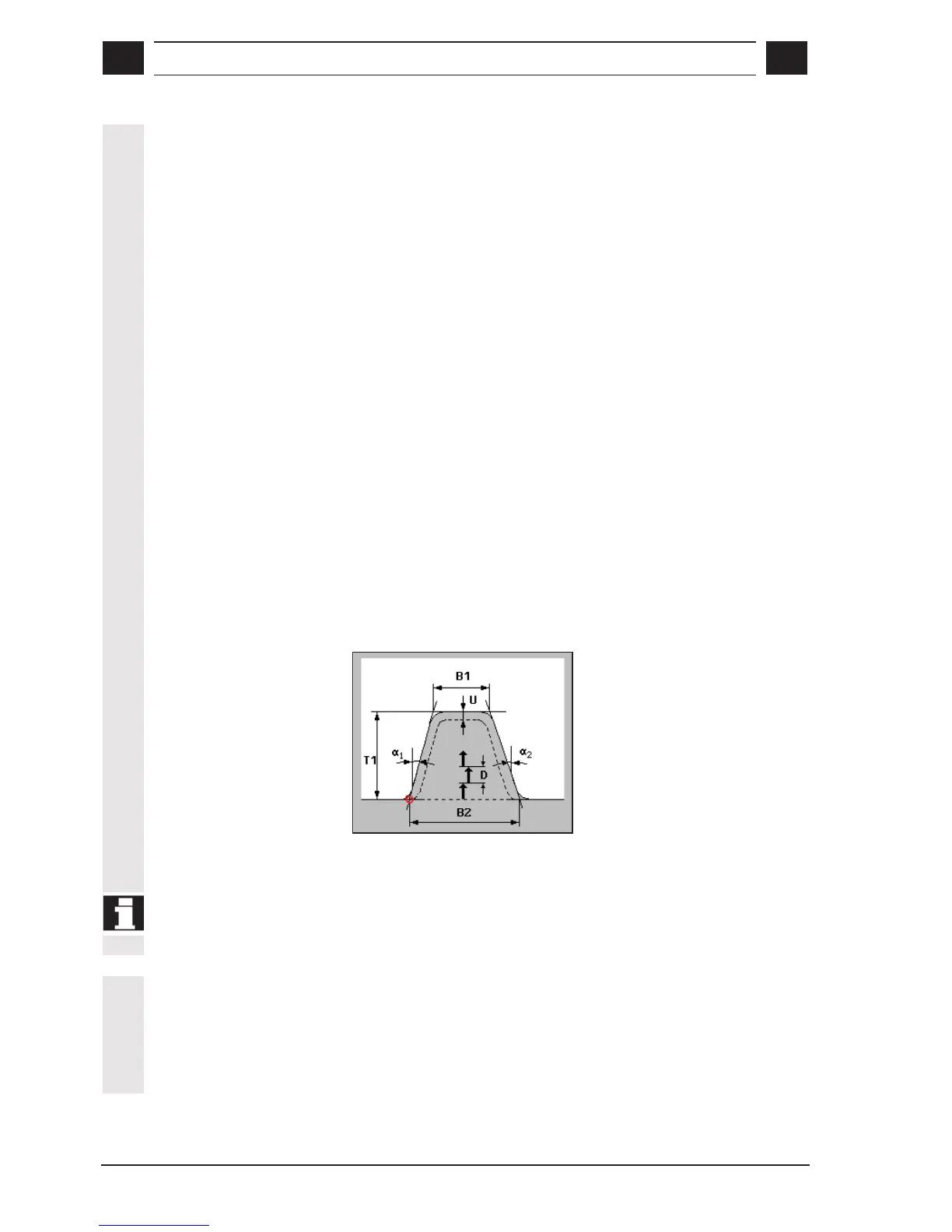

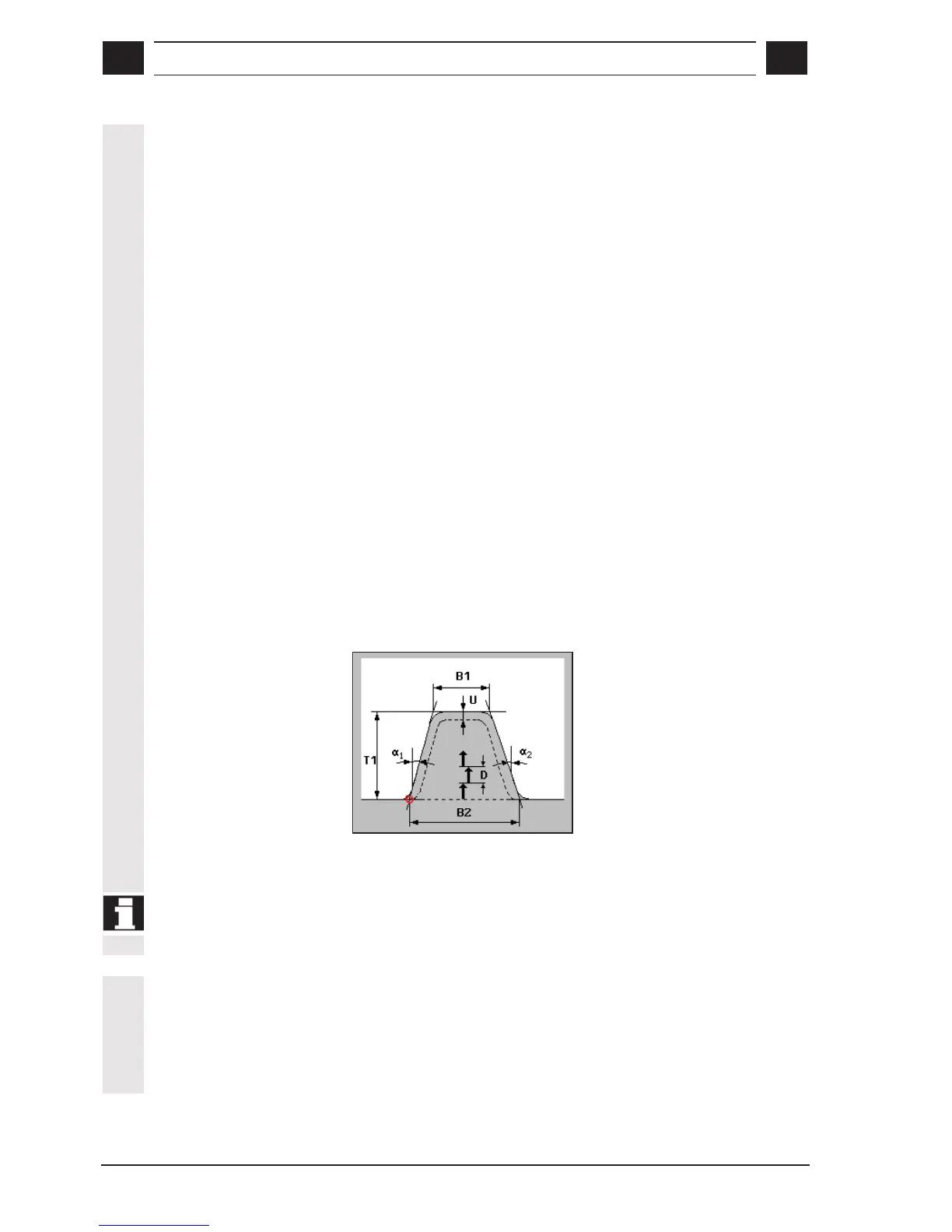

α

αα

α0

Angle of slope

The oblique angle in relation to the reference axis on which the groove

is to be machined is programmed with parameter

α

αα

α0. The angle can

be set to values of between –180° and +180°.

• Longitudinal groove: α

0

= 0° Þ parallel to Z axis

• Face groove: α

0

= 0° Þ parallel to X axis

• α

0

is positive when rotational direction of X axis Þ Z axis

α

αα

α1

,

α

αα

α2

Edge angle

Flank angles are separately entered so that asymmetrical grooves can

be described. The angles can be set to values of between 0 and

< 90°.

R

n

, FS

n

The groove form is modified through the input of radii/chamfers on the

edge or base (n = 1 ... 4).

D

Infeed depth 1st cut

D=0 : 1st cut is executed straight to the final depth T1.

D>0 : The 1st and 2nd cut are executed at the infeed depth

D on alternate sides, to ensure a better chip clearance

and prevent tool breakage.

All other cuts are executed straight to the final depth

T1.

The lateral infeed for the alternate-sided cutting is automatically

defined in the cycle.

Alternate-sided cutting is not possible when the tool can only reach the

groove base at one position.

U

Finishing allowance

You can specify a finishing dimension for the groove base and flanks.

The workpiece material is rough-cut down to this finishing allowance

during roughing. Finally, a cut is made along the final contour with the

same tool.

Loading...

Loading...