7

08.97 Transformations

7.3 C

linder surface transformation: TRACYL

7

840D

NCU 571

840D

NCU 572

NCU 573

FM-NC

810D

840Di

Siemens AG 2000. All rights reserved

SINUMERIK 840D/840Di/810D/FM-NC Programming Guide Advanced (PGA)

−

04.00 Edition

7-243

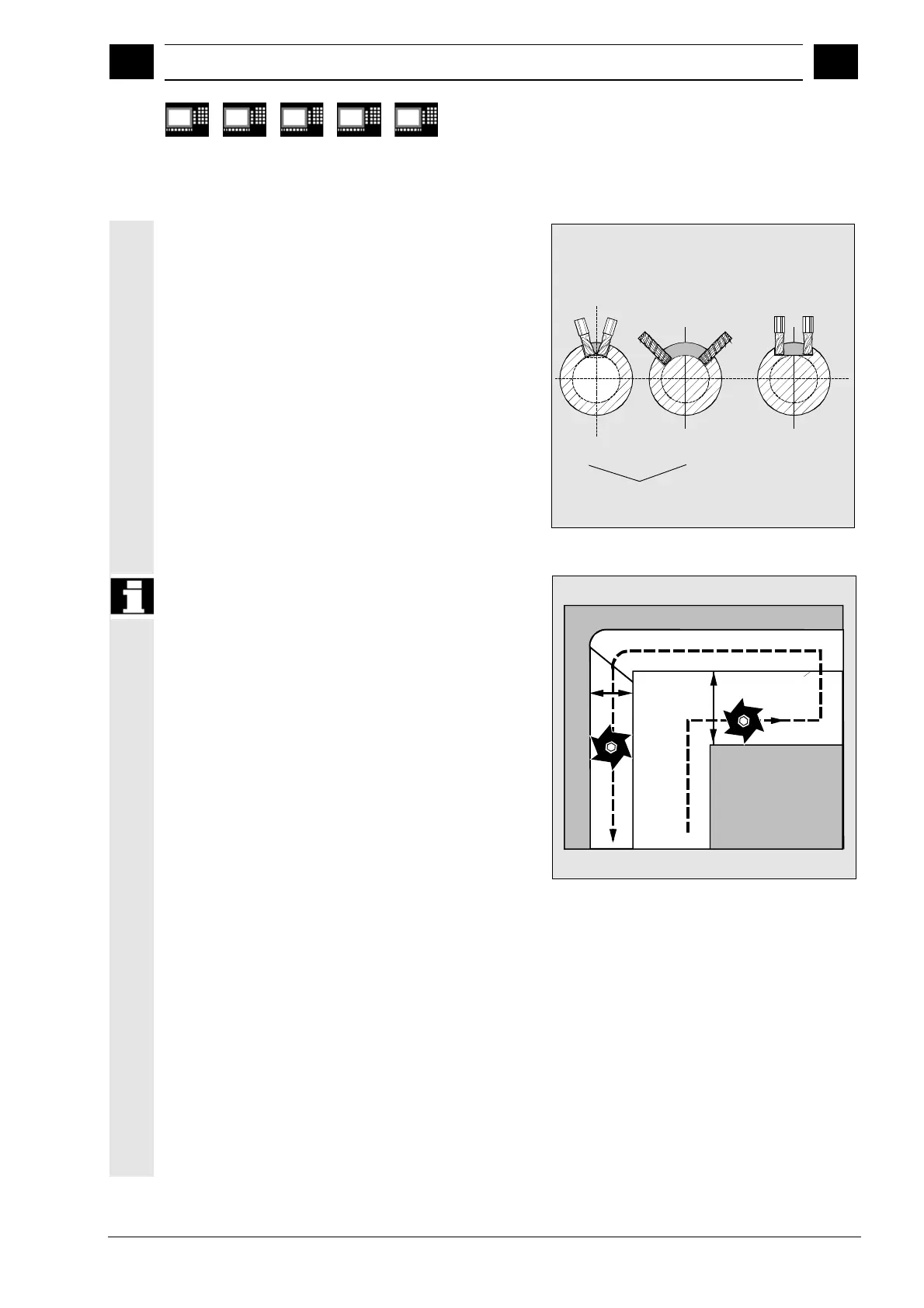

Groove cross section

With axis configuration 1, grooves along the rotary

axis are only limited in parallel if the groove width

matches the tool radius.

Grooves parallel to the circumference (transverse

grooves) are not parallel at the start and end.

Longitudinal

groove

Transverse

groove

Without groove wall

compensation in axis

configuration 2

Longitudinal groove

limited in parallel with

groove wall

compensation in

axis configuration 2

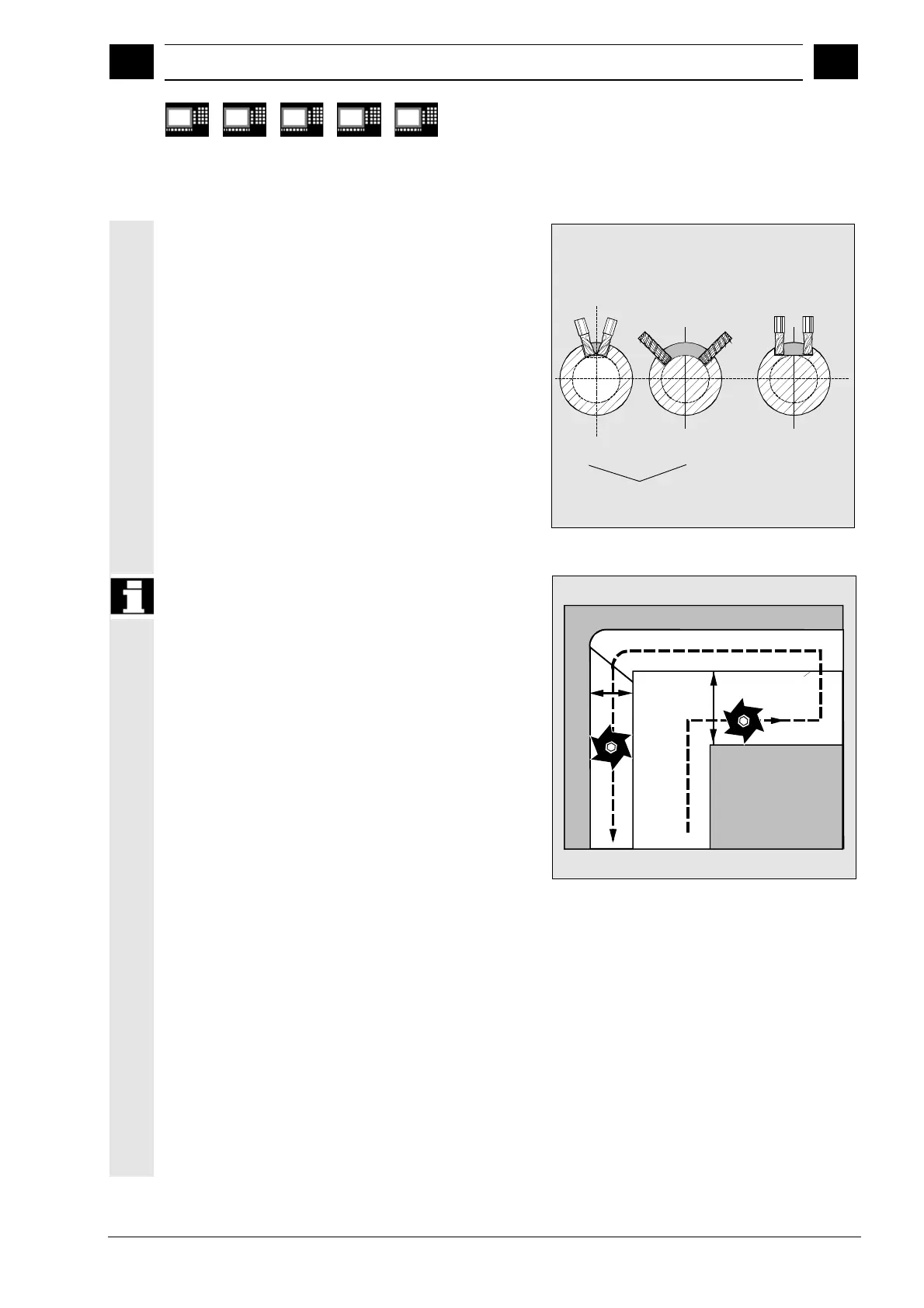

Offset contour normal OFFN

For milling grooves with TRACYL, the groove

•

center line is programmed in the part

•

program, the groove width via OFFN.

OFFN only becomes active when tool radius

compensation

is selected, to protect the side of the groove from

being damaged. Further, OFFN>=tool radius is

advisable to exclude any possible damage to the

opposite side of the groove.

A part program for milling a groove usually consists

of the following steps:

1. Select tool

2. Select TRACYL

3. Select suitable coordinate offset (FRAME)

4. Positioning

5. Programming OFFN

6. Select TRC

7. Approach block (enter TRC and approach side

of the groove)

8. Contour of groove center line

9. Deselect TRC

10. Retract block (exit TRC and retract from side of

groove)

11. Positioning

12. TRAF OOF

13. Select original coordinate offset (FRAME) again

OFFN

Programmed

contour

Loading...

Loading...