Feedrate Control and Spindle Motion

7.4 Positioning spindles (position-controlled axis operation) (SPOS, M19 and SPOSA)

Fundamentals

7-16 Programming Manual, 10.2004 Edition, 6FC5 298-7AB00-0BP1

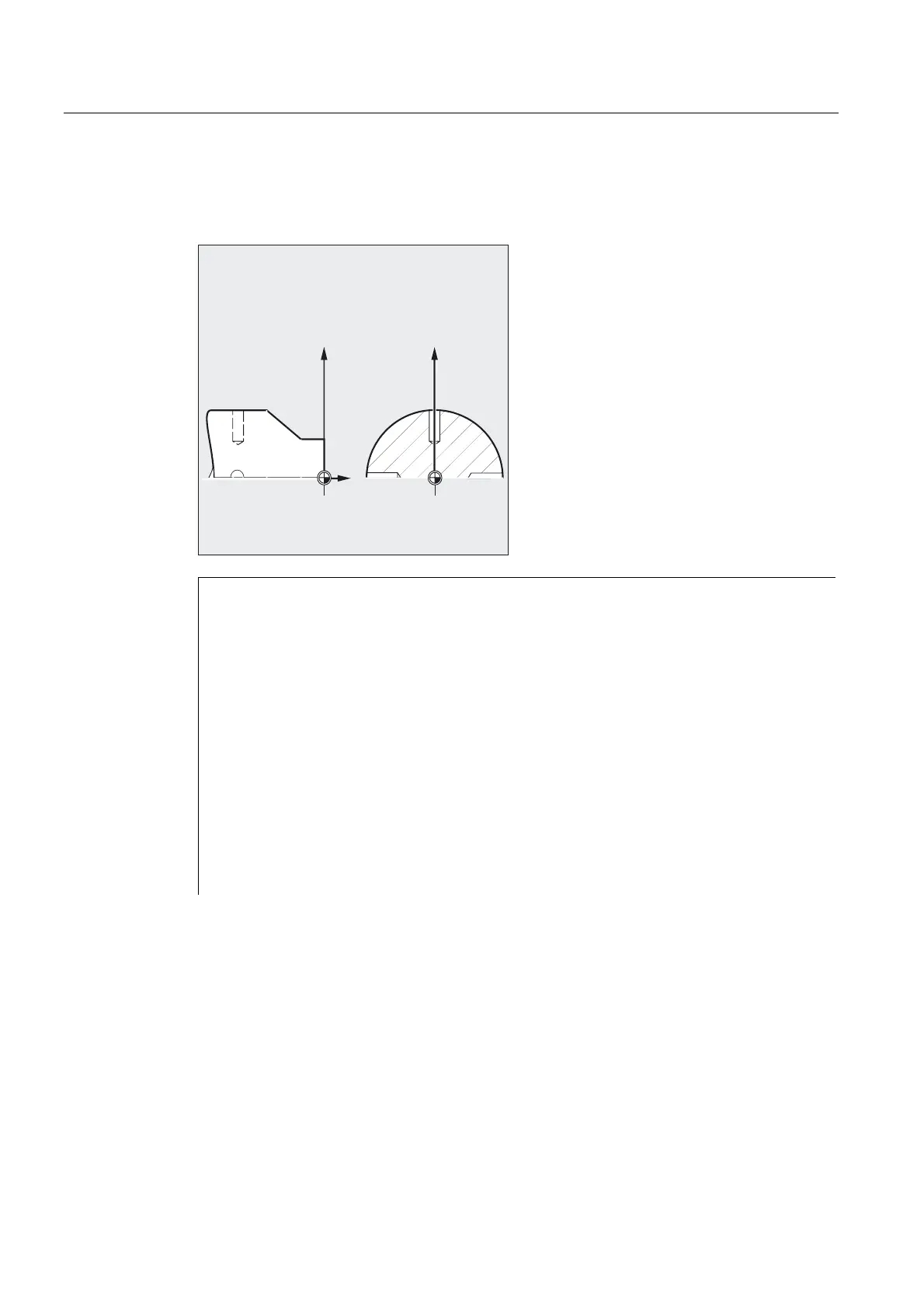

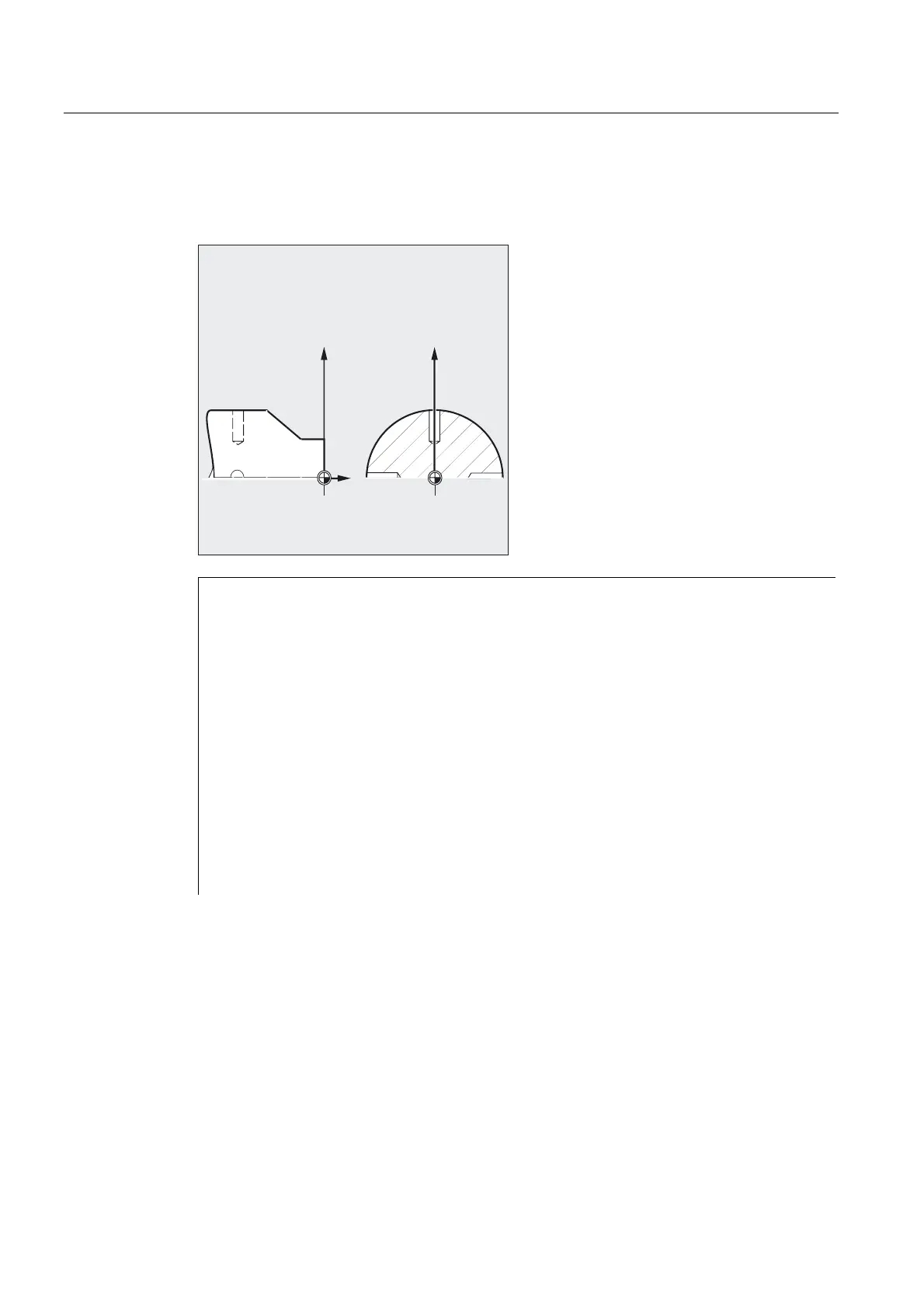

Example of drilling cross holes in turned part

Cross holes are to be drilled in this turned part. The running drive spindle (master spindle) is

stopped at zero degrees and then successively turned through 90°, stopped and so on.

=

; ;

....

N110 S2=1000 M2=3 ;Switch on cross drilling attachment

N120 SPOSA=DC(0)

;Position main spindle directly at 0°,

;the program will advance to the next block immediately

N125 G0 X34 Z-35 ;Switch on the drill while the spindle is being positioned

N130 WAITS ;Wait until the main spindle reaches its position

N135 G1 G94 X10 F250 ;Feedrate in mm/min (G96 is suitable only for the multi-

edge turning

;tool and synchronous spindle, but not for

;power tools on the cross slide)

N140G0 X34

N145 SPOS=IC(90)

;The spindle is positioned through 90° with read halt in a

;positive direction

N150 G1 X10

N155 G0 X34

N160 SPOS=AC(180)

;The spindle is positioned at 180° with respect to the

;spindle zero point

N165 G1 X10

N170 G0 X34

N175 SPOS=IC(90) ;The spindle turns in

;a positive direction through 90° from the absolute 180°

position, ending up in the

;absolute 270° position.

N180 G1 X10

N185 G0 X50

...

Loading...

Loading...