Programming Motion Commands

4.15 Thread cutting with constant lead (G33)

Fundamentals

4-54 Programming Manual, 10.2004 Edition, 6FC5 298-7AB00-0BP1

Note

If no starting point offset is specified, the "starting angle for thread" defined in the setting

data is used.

4.15.1 Programmable run-in and run-out paths (DITS, DITE)

Function

The commands DITS (Displacement Thread Start) and DITE (Displacement Thread End)

can be used to define the path ramp for acceleration and deceleration, in order to modify the

feedrate if the tool run-in and run-out paths are too short:

• Run-in path too short:

The band at the thread run-in provides insufficient space for the tool start ramp - a shorter

ramp must therefore be defined with DITS.

• Run-out path too short

The band at the thread run-out provides insufficient space for the tool deceleration ramp,

giving rise to danger of collision between the workpiece and the tool edge.

A shorter tool deceleration ramp can be defined with DITE; however, a collision can still

occur.

Remedy: Program a shorter thread, reduce the spindle speed.

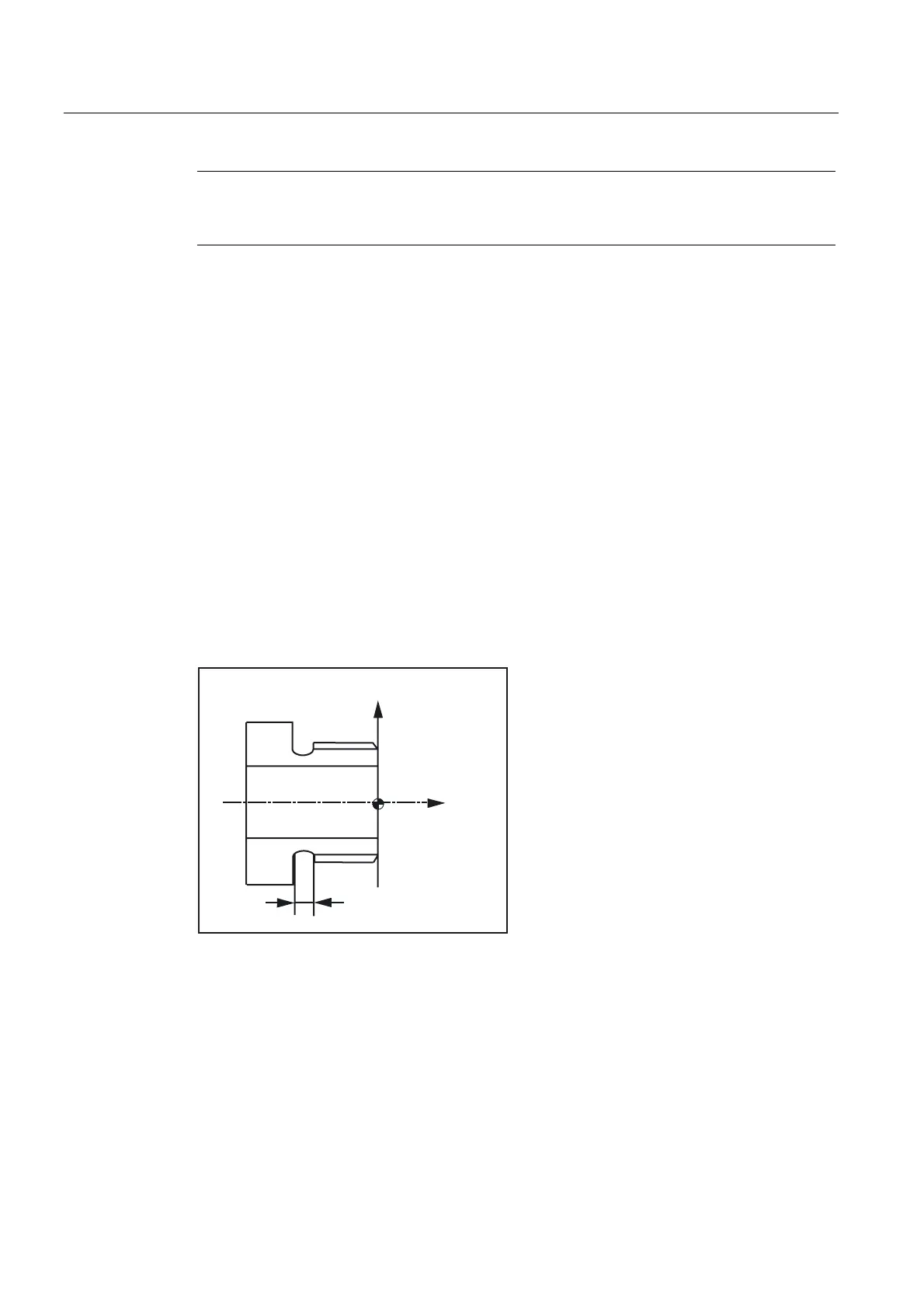

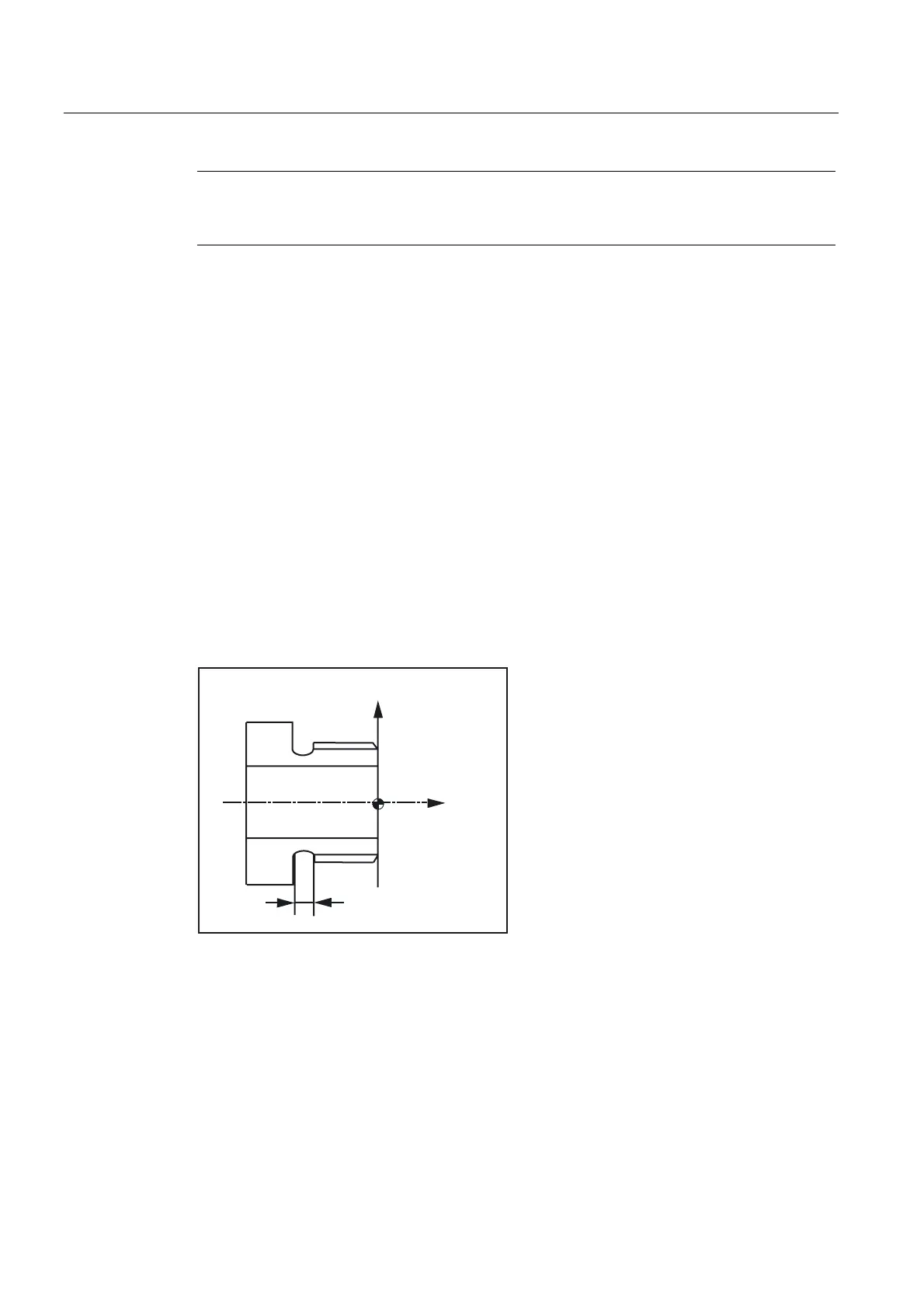

5XQLQUXQRXWSDWK

GHSHQGLQJRQGLUHFWLRQRI

PDFKLQLQJ

;

=

Programming

DITS=value

DITE=value

Loading...

Loading...