Special functions

9.1 Auxiliary function outputs

Fundamentals

Programming Manual, 10.2004 Edition, 6FC5 298-7AB00-0BP1

9-3

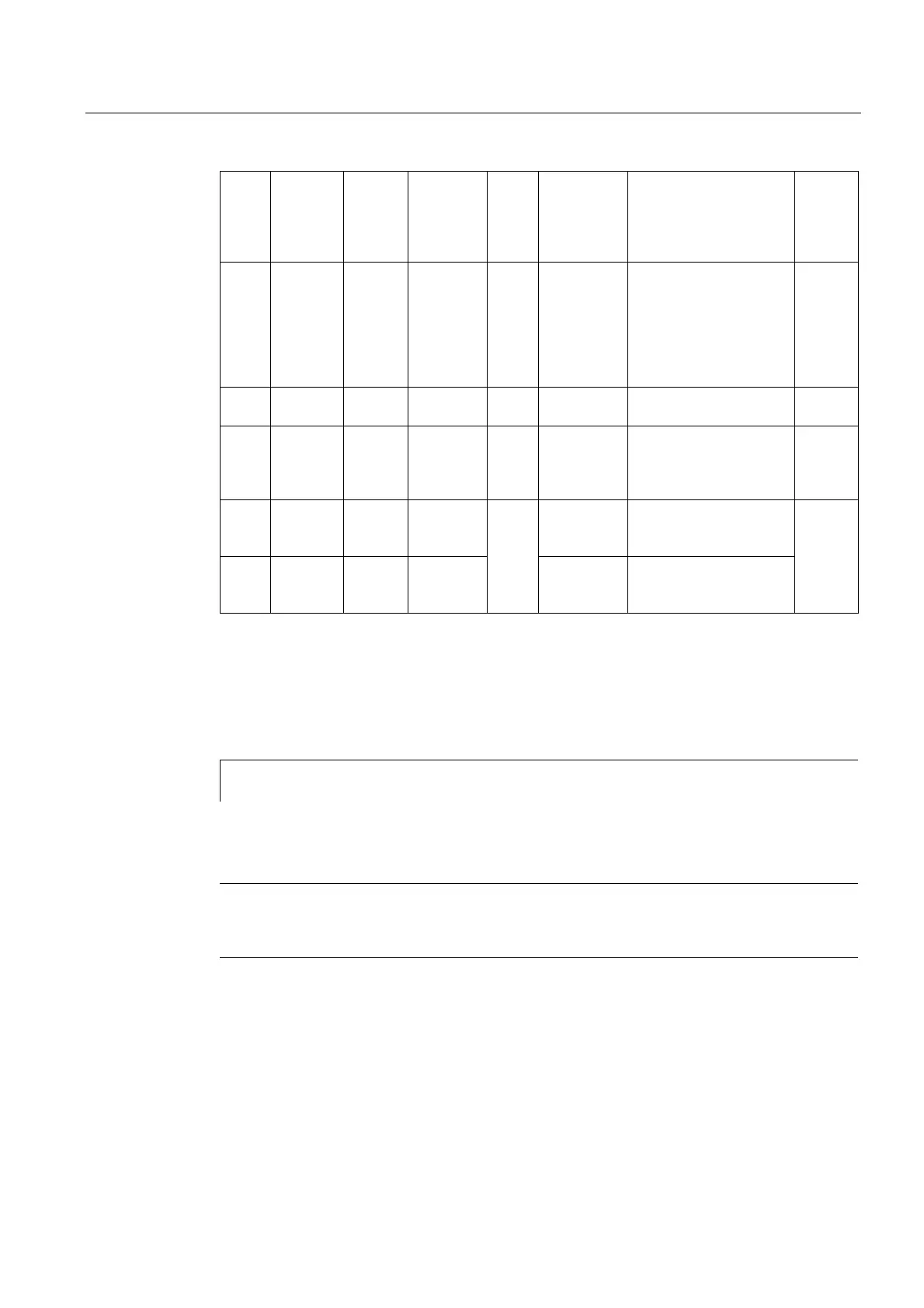

H Any 0 - 99 ±(max.

INT value)

±3.4028

ex 38

INT

REAL

Any Functions have no effect

in the NCK; only to be

implemented on the PLC

3

T Spindle

no.

(for active

tool

manage

ment)

1 - 12 0 - 32000

(or tool

names

with active

tool

managem

ent)

INT Tool

selection

Tool names are not

passed to the PLC

interface.

1

D 0 - 9 INT Tool offset

selection

D0 selection,

default D1

1

DL Location-

depende

nt offset

1 - 6 ±3.4028

ex 38

REAL See tool fine

offset

selection

/FBW/

Refers to previously

selected D number

1

F Path

feedrate

0 0.001 -

999

999.999

Path

feedrates

(FA) Axis No. 1 - 31 0.001 -

999

999.999

REAL

Axis

feedrates

6

The highest number for a type specified in the table must not be exceeded.

Example

M=QU(…)

H=QU(…)

N10 H=QU(735) ;High-speed output for H735

N10 G1 F300 X10 Y20 G64

N20 X8 Y90 M=QU(7)

M7 was programmed as a high-speed output, so continuous-path mode (G64) is not

interrupted.

Note

You should only use this function in individual cases, because it can affect the time

synchronization as a result of interaction with other function outputs.

Loading...

Loading...