'(& )( )'& &) ( &!& ")& &$(( $# Ć %&( $# #)" &&#$

7 - 11

Siemens AG ⋅ May 1998

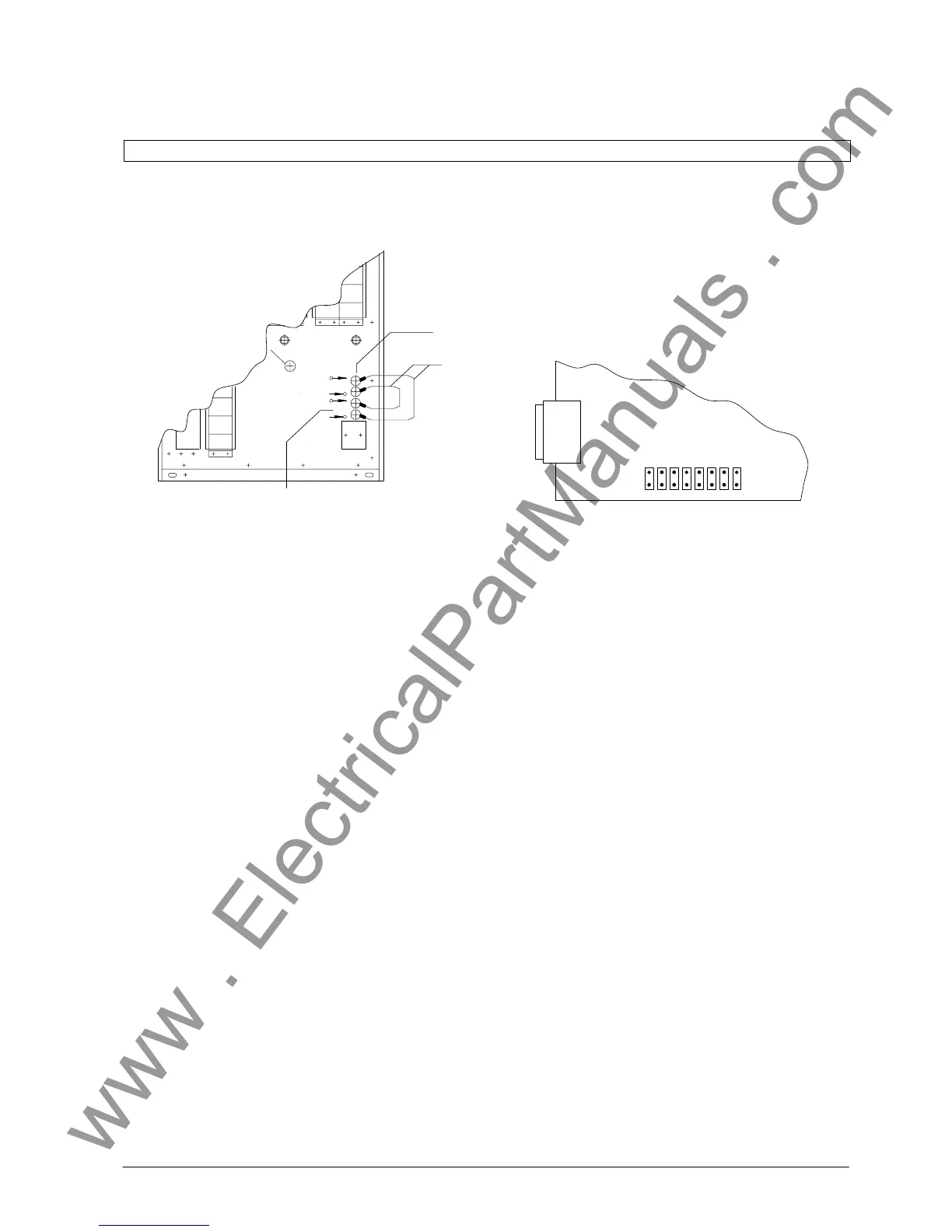

Figure 7.4 Connection of the interface points for

the test run

Connection of the two FO-terminals allows to

check the transmission channel for interruptions

(for max. FO-cable lengths of 700m).

A FO-coupler (part of the delivery) is used to conĆ

nect the FSMA plugs.

After finishing the test, the jumper must be remoĆ

ved and the cyclic protection test must be switĆ

ched on again.

b) Test run of the bay unit

If the test described in a) was run successfully,

then it is very likely that a failure in the bay unit

caused the channel disturbance.

Fitting jumper no 5 on the PFE module activates a

test function (refer to Fig 7.5). The jumper is deliĆ

vered together with the master unit.

The supplementary interface at the bay unit (refer

to Fig 2.5 and 7.4) simulates the master unit for

the test run.

To run the test, the transmitter of the interface to

the master unit is connected to the receiver of the

supplementary interface and the receiver of the

interface to the master unit is connected to the

transmitter of the supplementary interface by a FO

cable (FO cables are delivered together with the

master unit).

In the event of a transmission error in control or

alarm direction, the alarm "Fail com CU"

is issued. This alarm can be allocated

to an LED. After about 0.5 s service without faiĆ

lure, the alarm is cancelled.

PC interface

87654321

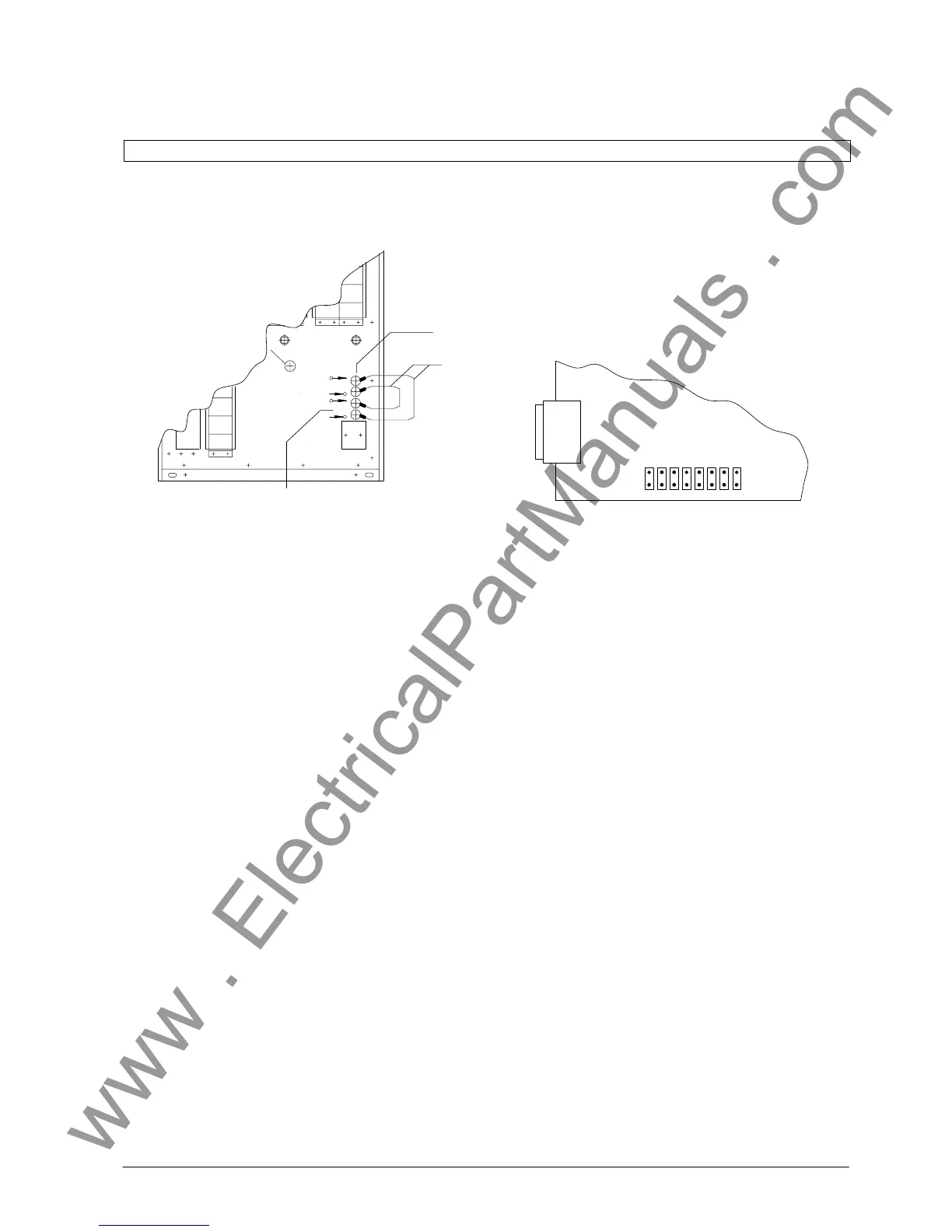

Test function "service without master unit"

Fit jumper to location 5

Figure 7.5 Location of jumpers on the module PFE of the

bay unit

Start-up can be completed successfully even with a

failed bay (FE or FO-link defective).

To achieve this, the faulty bay must be taken out of

service. This is done by parameterizing

( ).

The corresponding bay must be excluded from the

protection zone by "isolating".

The protection system allows service of the fault-free

bays until the defective bay unit or FO-cable is replaĆ

ced.

Loading...

Loading...