'(& )( )'& &) ( &!& ")& &$(( $# Ć %&( $# #)" &&#$

2 - 6

Siemens AG ⋅ May 1998

2.3.8 Operational and fault events

The 7SS52 supplies detailed data for the analysis of

faults as well as for operational events.

Up to 99 operational events and 40 fault events are

stored in a rotating buffer in the master unit.

D Operational events

Switching operations, (e.g. isolator switching),

protection status indications (e.g. start of cyclic

test), isolator status irregularities (running time,

auxiliary voltage failure, etc.) and other monitoring

functions belong to this group of events.

D Fault events

Trip signals in the event of busbar short-circuits,

circuit-breaker failure and transfer trip belong to

this group of events.

2.3.9 Self-monitoring

Hardware and software are continuously monitored;

irregularities are recognised instantly and annunĆ

ciated.

High security and availability are achieved by the conĆ

tinuous monitoring of:

1. the isolator status,

2. the trip circuits,

3. the measured currents,

4. the measured value transformation,

5. all supply voltages,

6. the program memories,

7. the program processing.

For diagnosis purposes in the event of device failures,

a dedicated data memory is available in the master

unit.

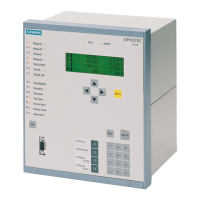

The busbar and breaker failure protection 7SS52 as a

system consists of the components

D master unit

D bay units

D data links (fibre-optical cables).

The master unit can be delivered in a SIPAC 19'' subĆ

rack for cubicle mounting or in a casing for surface /

wall-mounting. On account of the modular design,

different fitting variants can be coordinated with the

station configuration. The bay units are built into a

7XP20 casing for cubicle mounting or surface mounĆ

ting.

Prefabricated glas-fibre optical cables (62,5/125m)

with double-end FSMA plug connectors are used for

the data exchange. They are suitable for outdoor inĆ

stallation and can be delivered with specific anti-roĆ

dent protection.

Indoor cables may be used for centralized configuraĆ

tion of the bay units.

2.4.1 Bay units

2.4.1.1 7SS521x-5DA00-xAA0 for panel surface

mounting

For the variant "surface mounting" the bay units are

delivered in casings type 7XP2040-1.

The casing is completely metal-closed with a removaĆ

ble front cover with acrylic window. The integrated

button can be used for reset of the LEDs while the

front cover is fitted.

Earthing screws are at the left side of the casing.

The heavy-duty current terminals automatically short-

circuit the current transformer when the module is

withdrawn.

All signals including the auxiliary voltage are connecĆ

ted to double-level terminals. The device has 28 conĆ

nection terminals at the bottom side and 50 more terĆ

minals at the top side. In each level the terminals are

numbered from left to right.

Loading...

Loading...