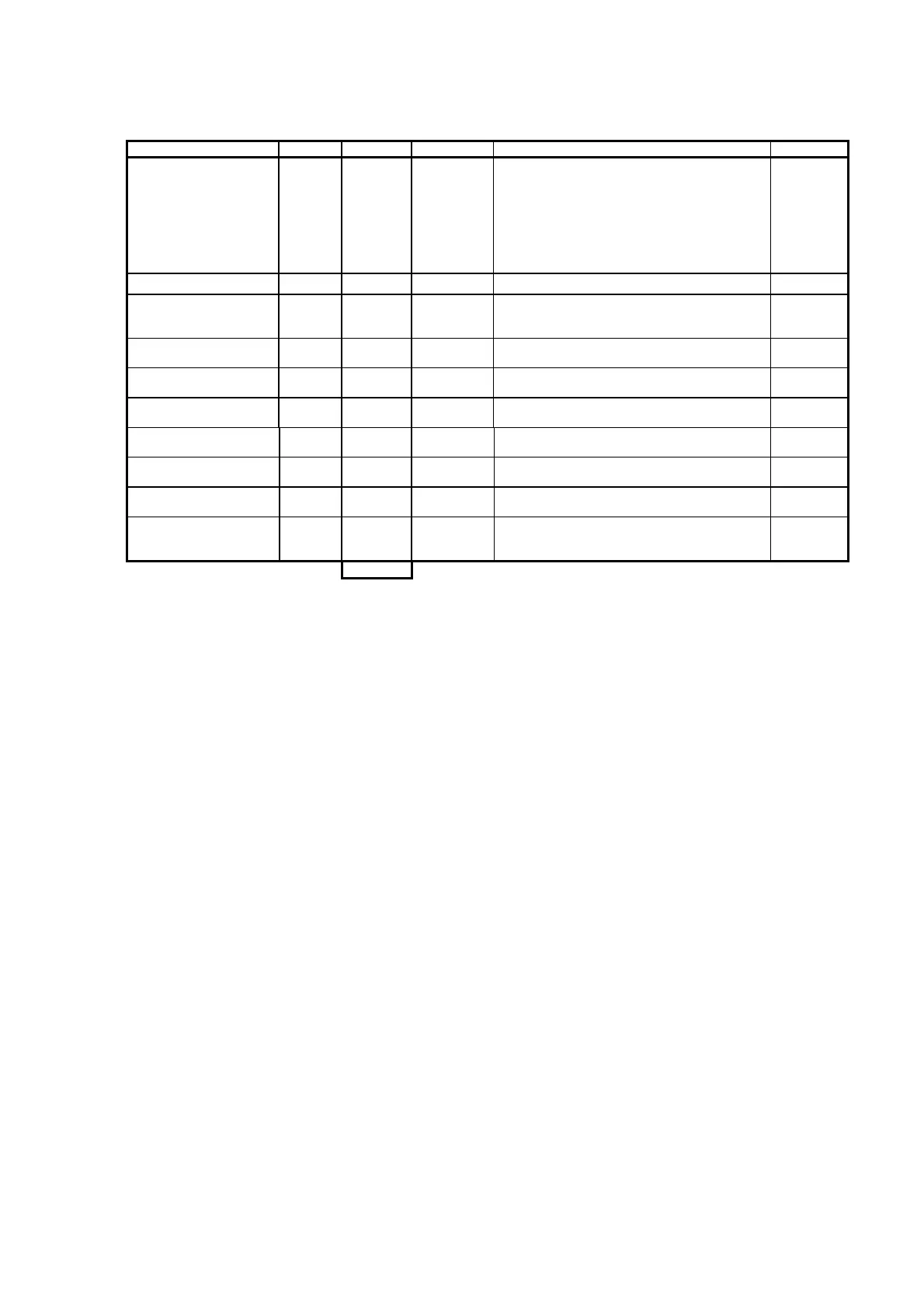

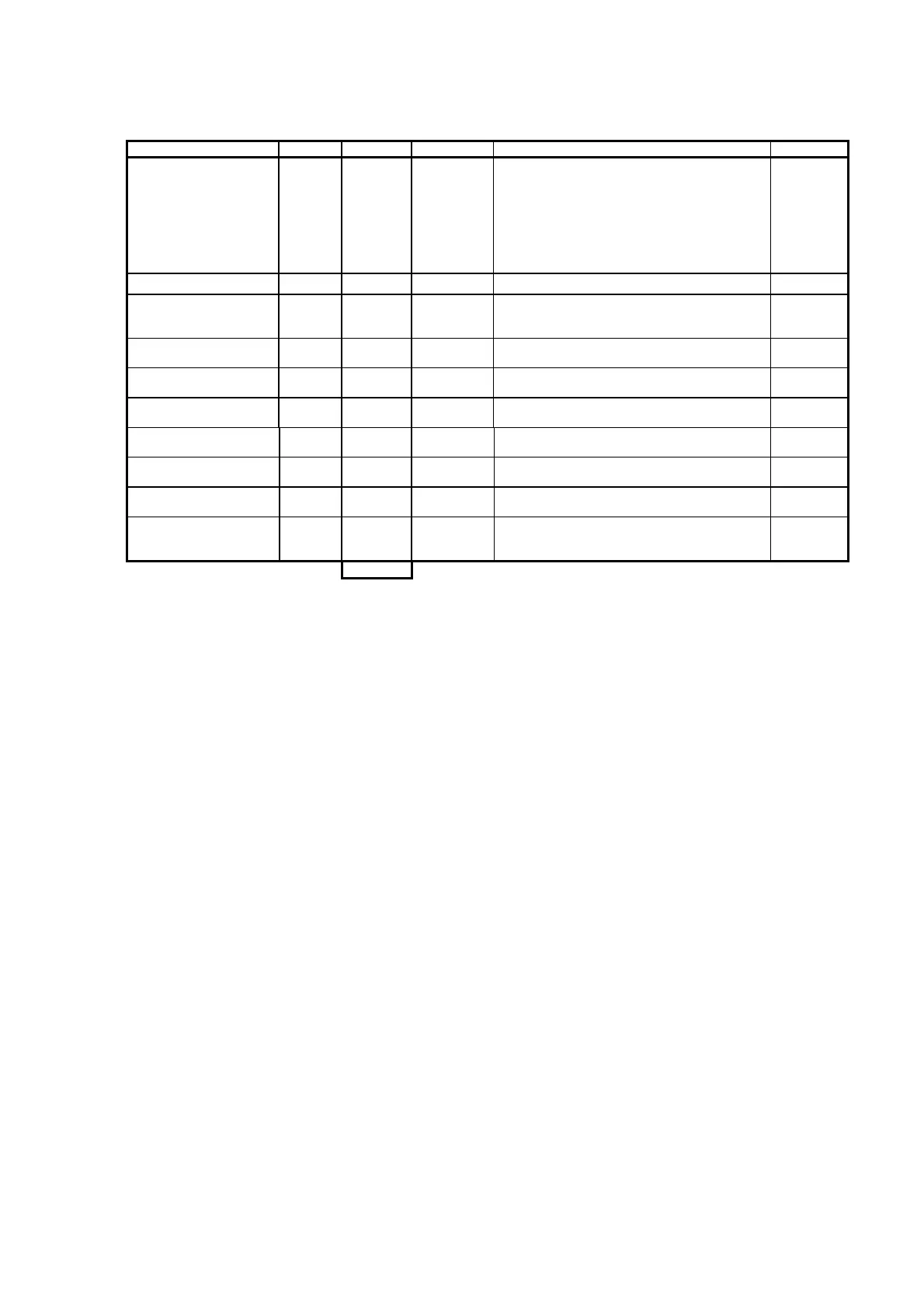

WEIGHING FUNCTIONS AND PARAMETERS

Name Type Address Default Range of Values / Meaning Reference

Operating mode

BYTE DBB111 0 Operating mode:

0 NAWI filling procedure

1 NAWI emptying procedure

2 Force measurement

3 Belt scale

4 Loss-in-weight scale

5 Bulk flow measurement device

5.2.30

Reserve_3_110 BYTE DBB112 0 Reserved

Load cell type

BYTE DBB109 0 0: analog load cell

1: METTLER TOLEDO type WM or WMH

2...255 analog load cell

5.2.37

Timeout digital LC WORD DBW110 240 Timeout in ms for receiving the cyclic weight

value of the digital load cell

5.2.38

Regulations STRING

[4]

DBB116 “----“ "OIML" : = Regulation code OIML

"----": = No regulation code

5.2.39

Weight unit

STRING

[4]

DBB122 kg Weight unit

5.2.40

Weight unit large STRING

[4]

DBB128 t Large weight unit

5.2.41

Length unit STRING

[2]

DBD134 m Length units (belt scale only)

5.2.42

U Factor REAL DBD138 1000 Conversion factor weight unit > Large weight

unit

5.2.43

Determination time 3

TIME DBD140 10000 Adjustment or zero setting time for dynamic

zero setting, taring or adjusting 0... max. 900

000 ms (belt scale only)

5.2.44

144

Table 5-2 DR3 Allocation

5.2.1 DR3 - Adjustment Digits 0, 1, 2, 3, 4, for the Zero Point and Adjustment Weights 1,

2, 3

, 4

The analog measurement value coming from the load cells is converted into a

digital value with an analog-digital converter. A weight value is then calculated from

this digital value. All functions of the SIWAREX FTC then uses this weight value for

executing their task.

To calculate the weight value from the digital value, the characteristic curve of the

measurement system must be determined. In the simplest case, the characteristic

curve is defined by points 0 and 1. The first operating point (point 0) is always

determined by the empty scale alone with its own construction weight. The weight

of its own construction, the scale load cells deliver a measurement voltage to the

SIWAREX FTC. After the analog-digital conversion of the measurement voltage,

the digital value (adjustment digit 0) is assigned the zero point (zero weight).

For determining the average value of the adjustment point for the belt scale (zero

point, adjustment weight) over a predefined period of time, the determination time

must be defined. This time entry is not applicable for other operating modes.

If the scale is loaded with a known calibration weight (e.g. with 50 % of the

measurement range), then the second operation point can be determined. The new

digital value from the analog-digital converter is now assigned the calibration weight.

The characteristic curve can be further adjusted using a maximum of three other

points that must lie above point 1.

SIWAREX FTC

5-35

Loading...

Loading...