EN

4. Technical data

- 44 -

951-180-083-EN

Version 01

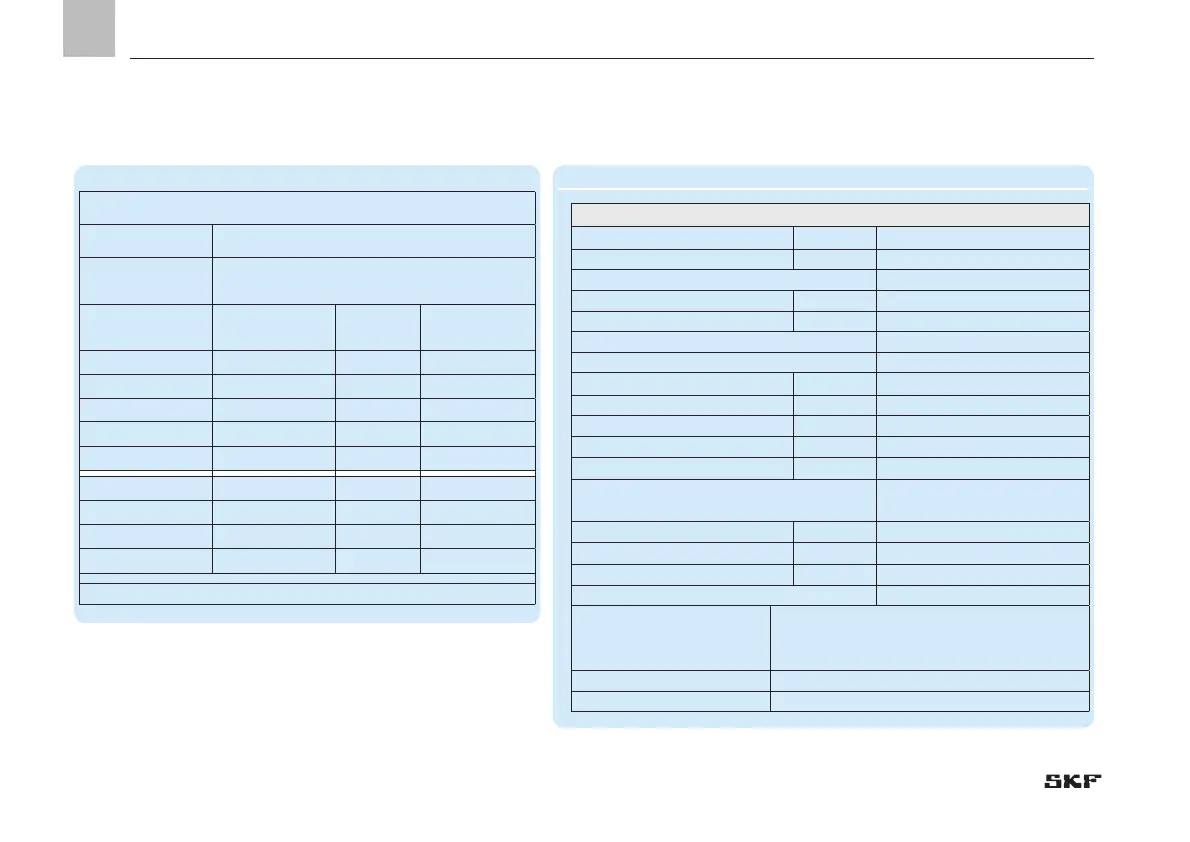

4.2 Volume data for VPK metering device sections

4.2.1 Basic design of VPK progressive metering device

Volume data for VPK metering device sections, Table 6

Max. inlet volumetric flow 500cm

3

/min

Nominal volume Minimum volume

1

)

(at maximum

stroke)

(at compulsory stroke, design value only under

difficult conditions)

Volume per cycle

and outlet

Volume per cycle

and outlet

Number of

outlets

Description of

the sections

[cm

3

] [cm

3

]

0.05

0.04 2 05T

0.10 0.08 2 1T

0.20 0.14

2

2T

0.30 0.18

2

3T

0.10 0.08

1

05S

0.20 0.16

1

1S

0.40 0.28

1

2S

0.60 0.36

1

3S

1) See explanation in Chapter 3.3, Information on volume data.

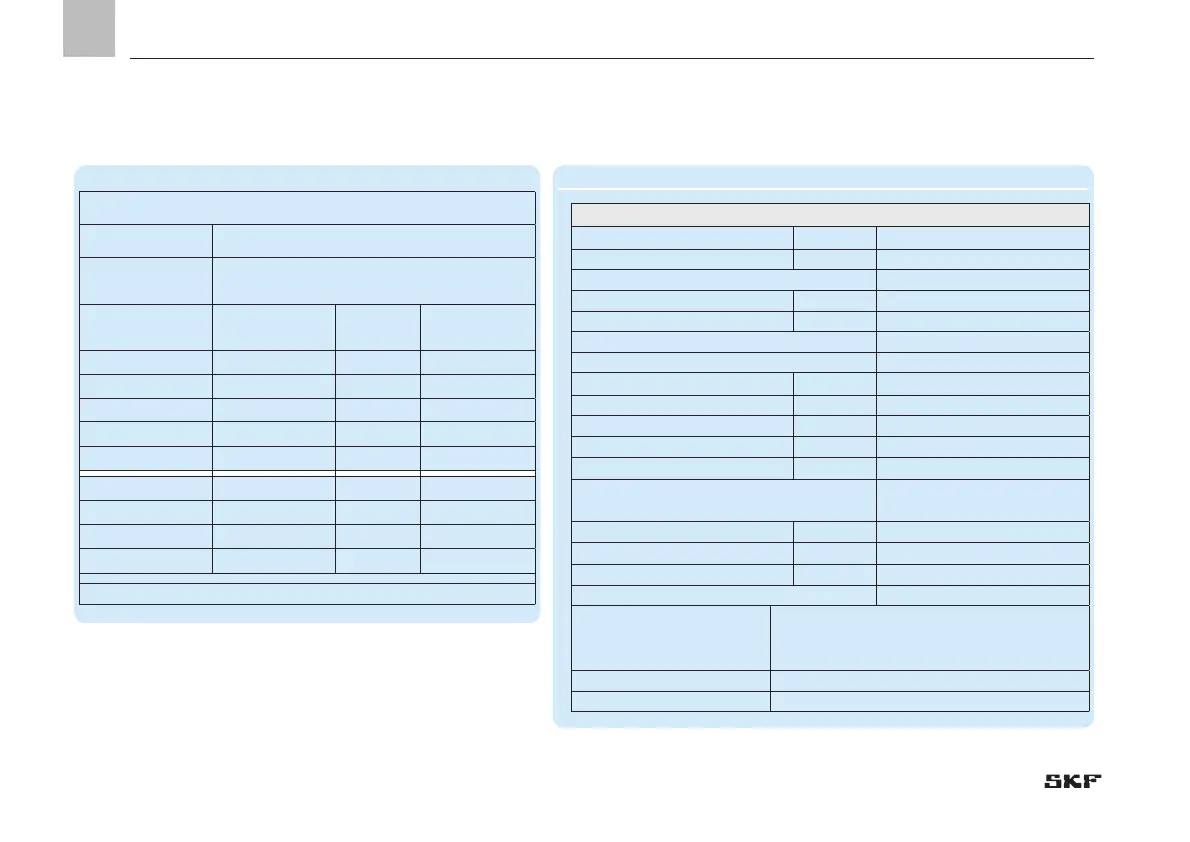

Progressive metering device VPK, basic design, Table 7

VPK Basic design with terminal for equipotential bonding

Type hydraulically controlled

Mounting position Any

Ambient temperature range -25 to +90 °C

- with cycle indicator -20 to +70 °C

Metering device sections See Table 1

Used outlets, internal connection 3 to 20

Used outlets, external connection 1 to 19

Inlet and outlet threads

VPKM (metric thread) M10x1

VPKG (inch thread) G1/8

Material

Inlet plate, separator plate and end plate Steel, tinned/nitrile-butadi-

ene rubber

Sections (piston plates) Steel, galvanized

Hydraulic system

Operating pressure max.: Oil 200 bar, grease 300 bar

Volume per outlet and cycle See Table 9

Lubricant Mineral oils, greases based on mineral oil,

environmentally friendly and synthetic oils

and greases

Dynamic viscosity > 12 mm

2

/s

Worked penetration ≥ 265 x 0.1 mm (up to NLGI Grade 2)

Loading...

Loading...