Installation Waukesha Cherry-Burrell

®

Brand Universal 3 Pump

Page 20 95-03103 11/2018

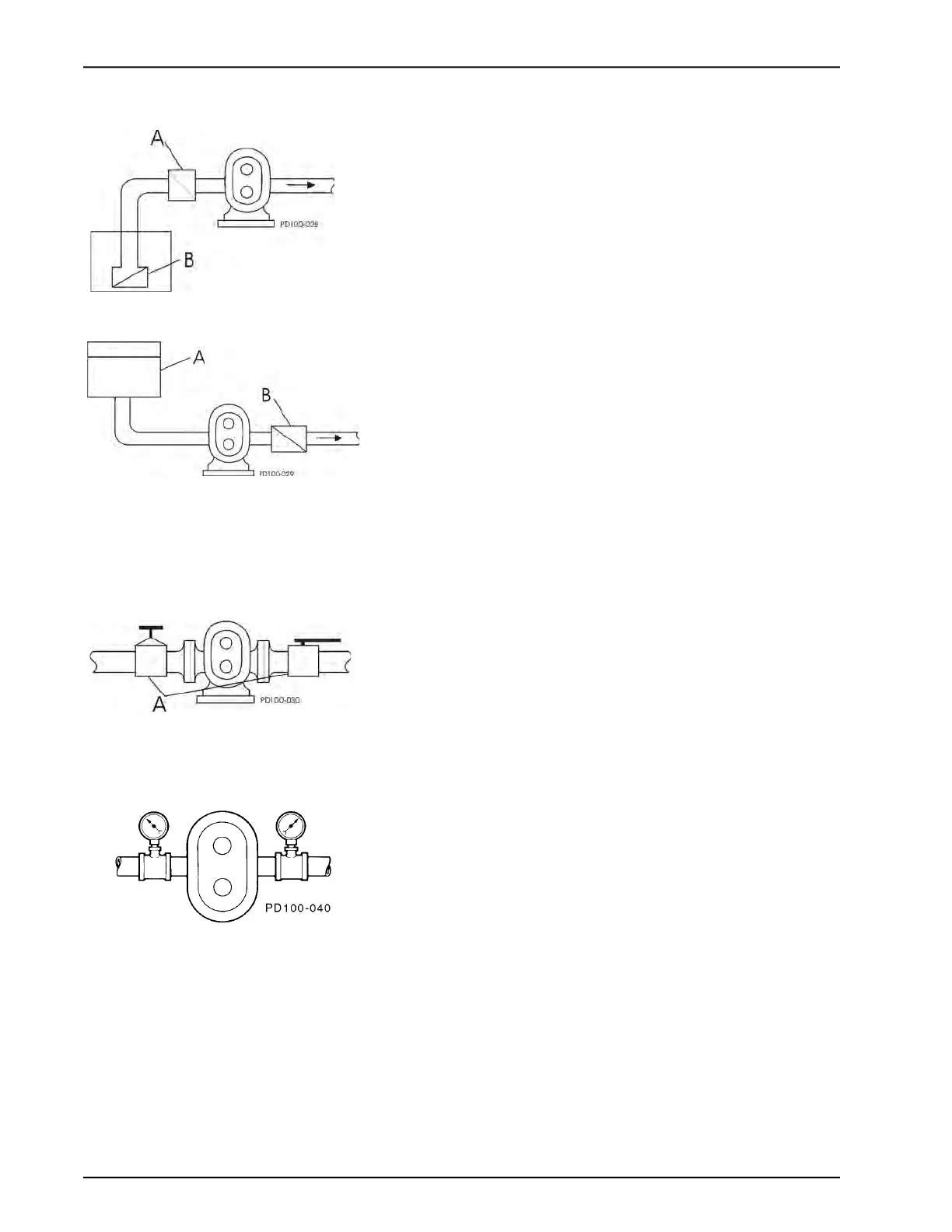

Install Check Valves Inlet Side on Lift Applications

Use check valves to keep the inlet line full, particularly with low-

viscosity fluids (Figure 12).

Discharge Side

For systems with liquid under a vacuum, install a check valve on

the discharge side of the pump. The check valve prevents back-

flow (air or fluid) to aid in the initial start-up by minimizing the

required differential pressure supplied by the pump to start the

flow (Figure 13).

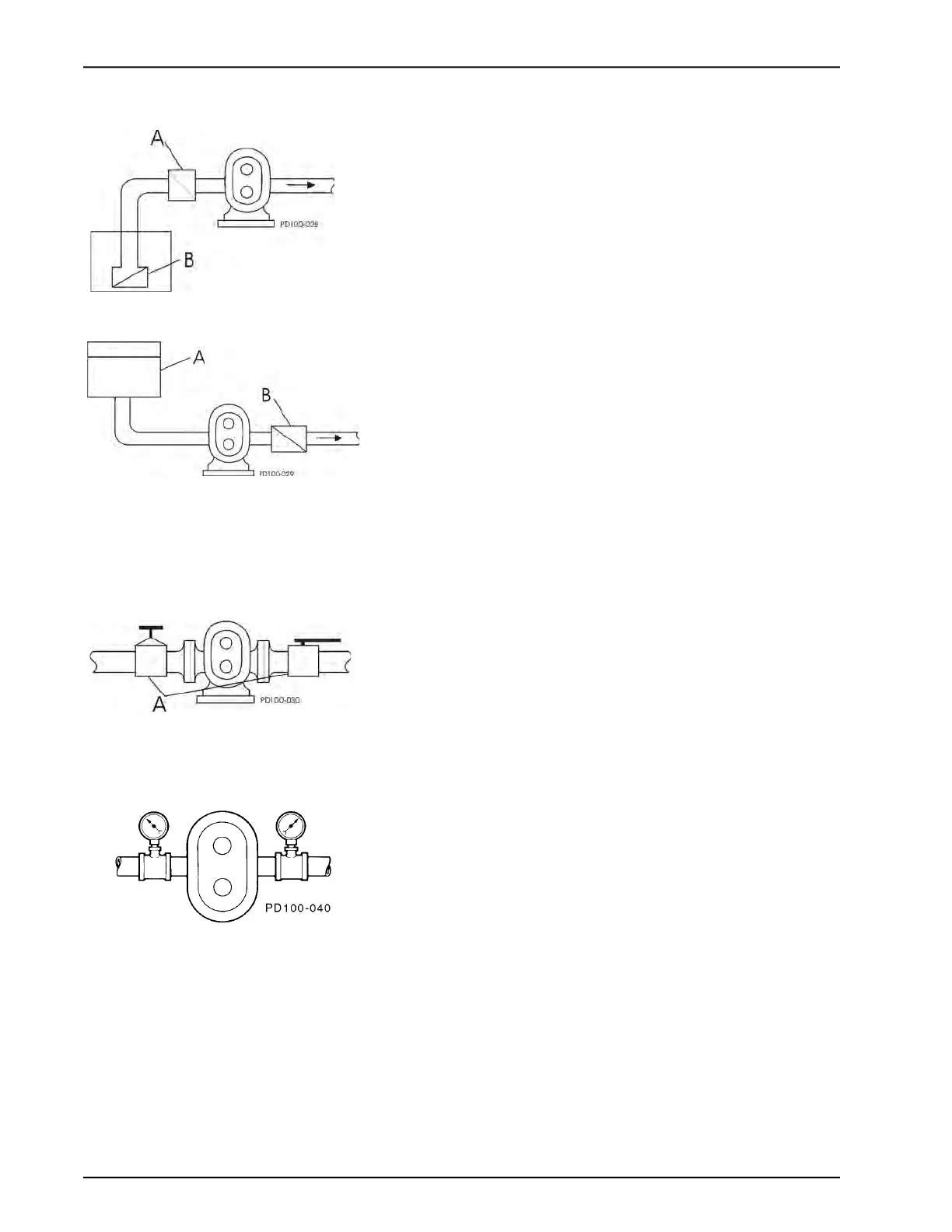

Install Isolation Valves

Isolation valves permit pump maintenance and safe pump

removal without draining the system (Figure 14, item A).

NOTE: Make sure the inlet flow is not restricted. Don’t start the

pump deadheaded, e.g., operated with no flow through it.

Install Pressure Gauges

Pressure and vacuum gauges provide valuable information about

pump operation (Figure 15). Wherever possible, install the

gauges to help provide information on the following:

• Normal or abnormal pressures

• Indication of flow

• Changes in pump condition

• Changes in system conditions

• Changes in fluid viscosity

Figure 12 - Inlet Check Valve

A. Inlet Check Valve

B. Foot Check Valve

A. Closed Tank - produces vacuum on

liquid (Low Absolute Pressure)

B. Check Valve (outlet)

Figure 13 - Discharge Check Valve

Figure 14 - Isolation Valves

Figure 15 - Pressure and Vacuum

Gauges

Loading...

Loading...