Waukesha Cherry-Burrell

®

Brand Universal 3 Pump Installation

11/2018 95-03103 Page 19

Install Connections and

Piping

These pumps are positive displacement design and will be

severely damaged if operated with closed valves in discharge or

inlet lines. The pump warranty is not valid for damages caused by

a hydraulic overload from operation or start-up with a closed

valve in the system.

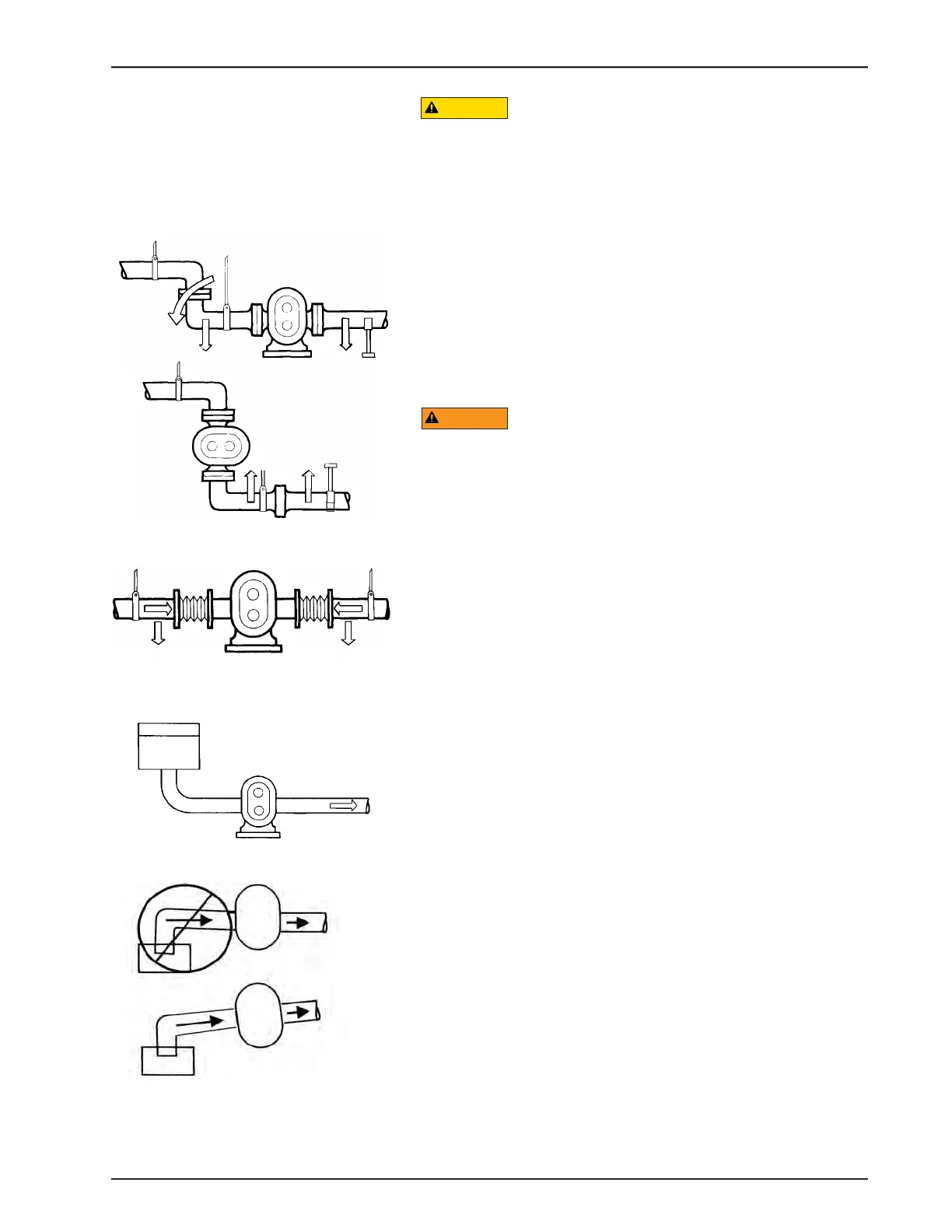

Piping Support

To minimize forces exerted on the pump, support all piping to the

pump independently with hangers or pedestals. Such forces can

cause misalignment of the pump parts and lead to excessive

wear of rotors, bearings, and shafts.

Figure 8 shows typical supporting methods used to independently

support each pipe, reducing the weight effect of piping and fluid

on the pump.

Do not exceed 50 lb (22.7 kg) load on pump inlet or discharge

ports. Exceeding this limit may cause damage to the pump.

Expansion Joints

Thermal expansion of piping can cause tremendous forces. Use

thermal expansion joints to minimize these forces on the pump.

Flexible joints can be used to limit transmission of mechanical

vibration. Ensure that the free ends of any flexible connections in

the system are anchored.

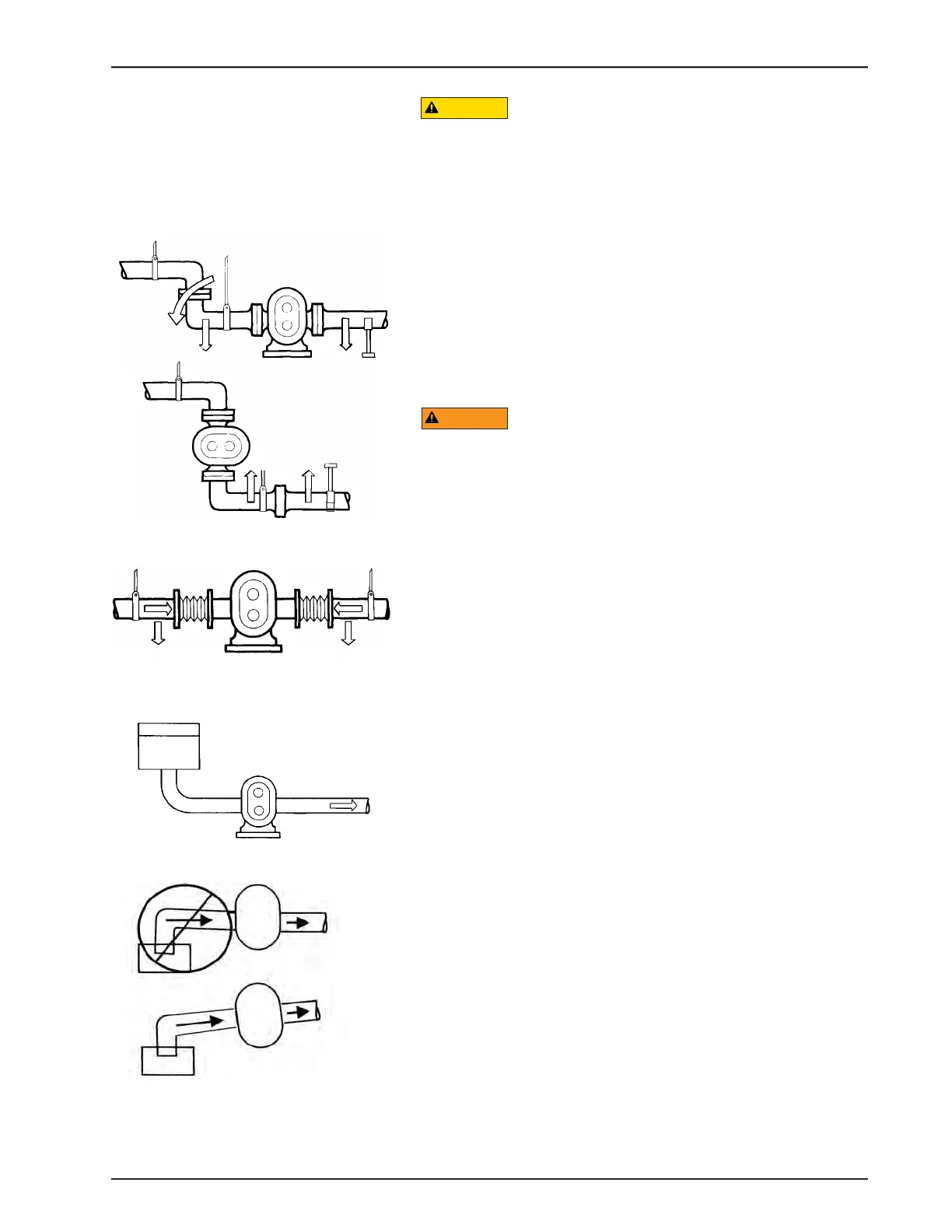

Inlet Piping

Install the pump below the supply liquid level to reduce the air in

the system by flooded suction, to prevent the pump from becom-

ing air-bound (Figure 10).

If the pump is installed above the supply liquid level, the piping on

the inlet side must slope up toward the pump, preventing air

pockets in the pipes (Figure 11).

Figure 8 - Piping Support

Figure 9 - Flexible Connections and

Supports

Figure 10 - Pump Below Supply

Recommended

Figure 11 - Piping Slope

NOT recommended

Recommended

Loading...

Loading...