DOCUMENT NUMBER:

L500-912.820 ISSUE JUL 20, 2016

AMENDMENT: 00

DATE:

CHAPTERPAGE 526

MAINTENANCE MANUAL STEMME S12

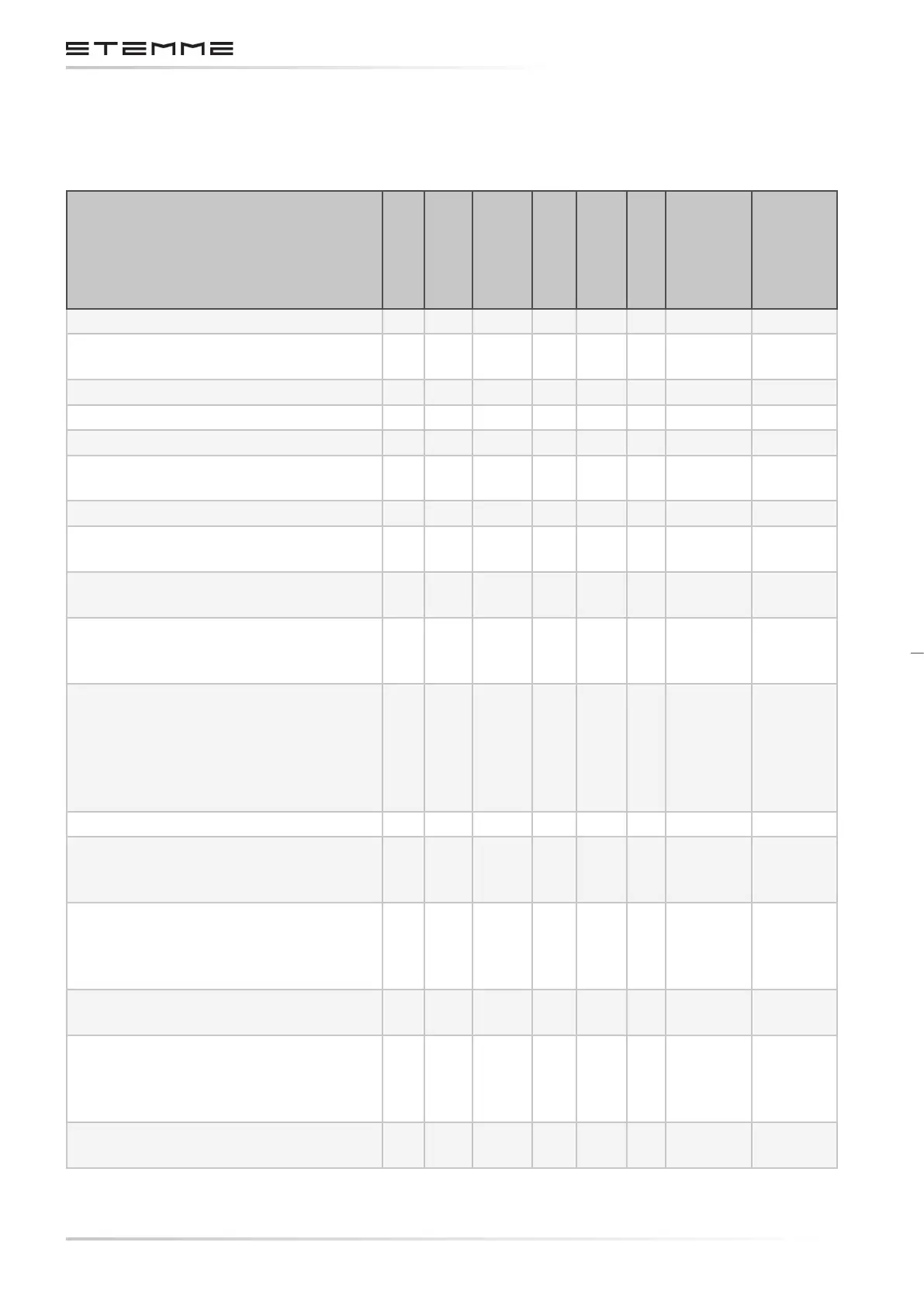

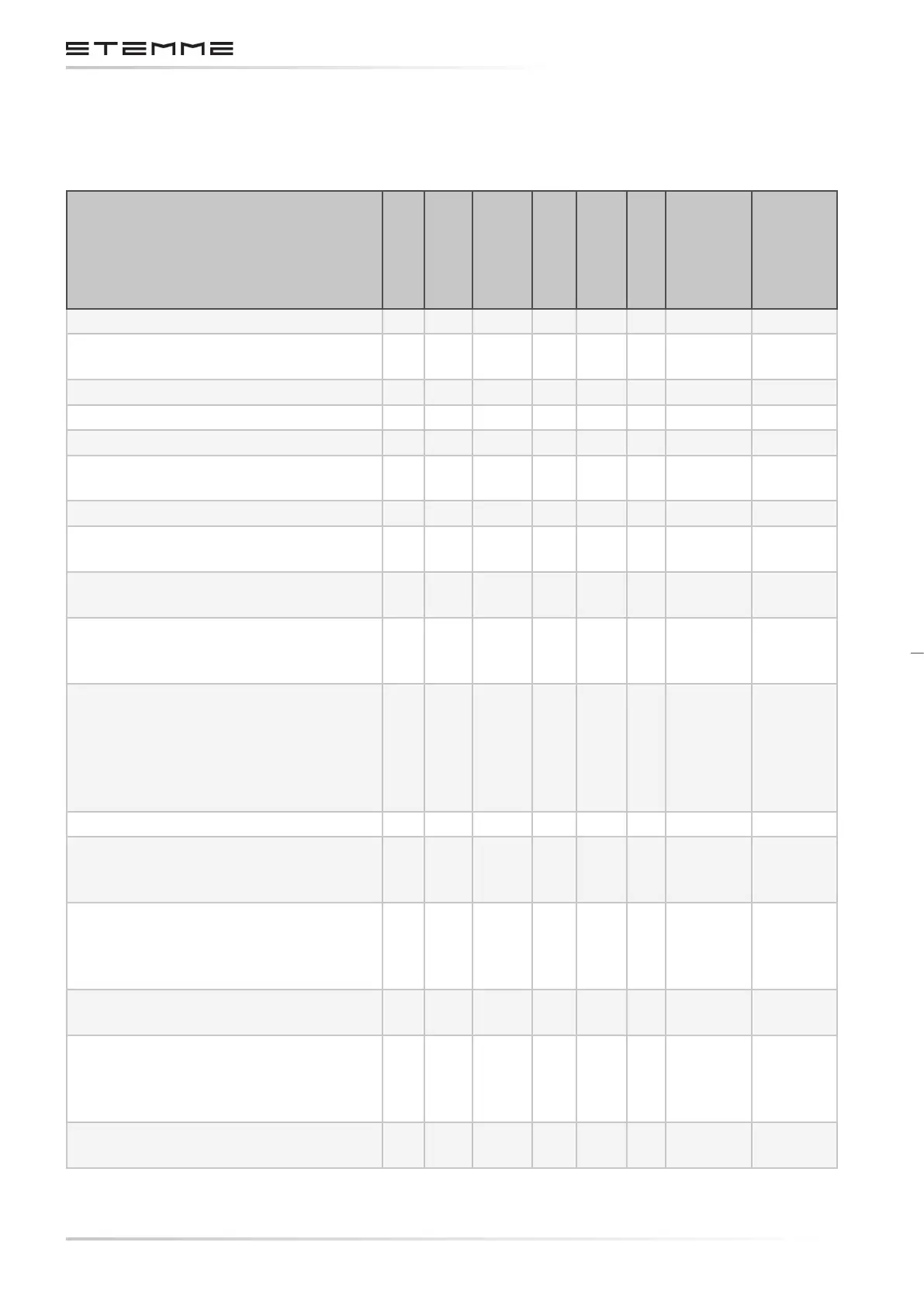

5.4.9 ENGINE AND ENGINE MOUNTINGS

(1) - use of leaded fuel more than 30% of operation

Type and Subject of Inspection

Break-in

Aircraft 100 hr

Engine 100 hr

Engine 200 hr

Engine 600 hr

Annual

Refer to

Section

Sign-o

1. Engine cleaning.

X X X

7.4.1.3

2. Visual inspection of engine

and auxiliaries.

X X X

7.4.1.4

3. Engine check for leakage.

X X X

7.4.1.5

4. Check of engine auxiliaries.

X X X

7.4.1.6

5. Check of waste-gate.

X X X

7.4.1.7

6. Lubricate the waste-gate axle

(waste-gate ap).

X X X

7.4.1.7

7. Check of engine gearbox.

X X X

7.4.1.8

8. Check magnetic plug for metal

particles or foreign matter.

X X X

7.4.1.9

9. Check of reduction gear

wheels.

X X

7.4.1.10

10. Removal/Assembly of the two

carburetors and carburetor

inspection.

X X X

7.4.1.11

1 1. Inspect the carburetor sockets

for damages and abnormali-

ties, checking for cracks, wear

and good condition. Take note

of changes caused by tem-

perature inuence.

X X

7.4.1.11

12. Check oat weight.

X X X

7.4.1.11

13. Check carburetor synchroniza-

tion – mechanical or pneumat-

ic synchronization.

X X

14. Check condition of fuel lines,

pressure connection lines and

compensating tube assy. at

carburetors and air box.

X X X

7.4.6.2

15. Check engine wiring and ca-

bles.

X X X

7.4.1.12

16. Visual inspection of the tem-

perature sensor and the oil

pressure sensor, inspect for

tight t and good condition.

X X

7.4.1.12

17. Check of V-belt tension of

additional auxiliary generator.

X X X

7.4.1.13

Loading...

Loading...