DOCUMENT NUMBER:

L500-912.820 ISSUE JUL 20, 2016

AMENDMENT: 00

DATE:

CHAPTERPAGE 613

MAINTENANCE MANUAL STEMME S12

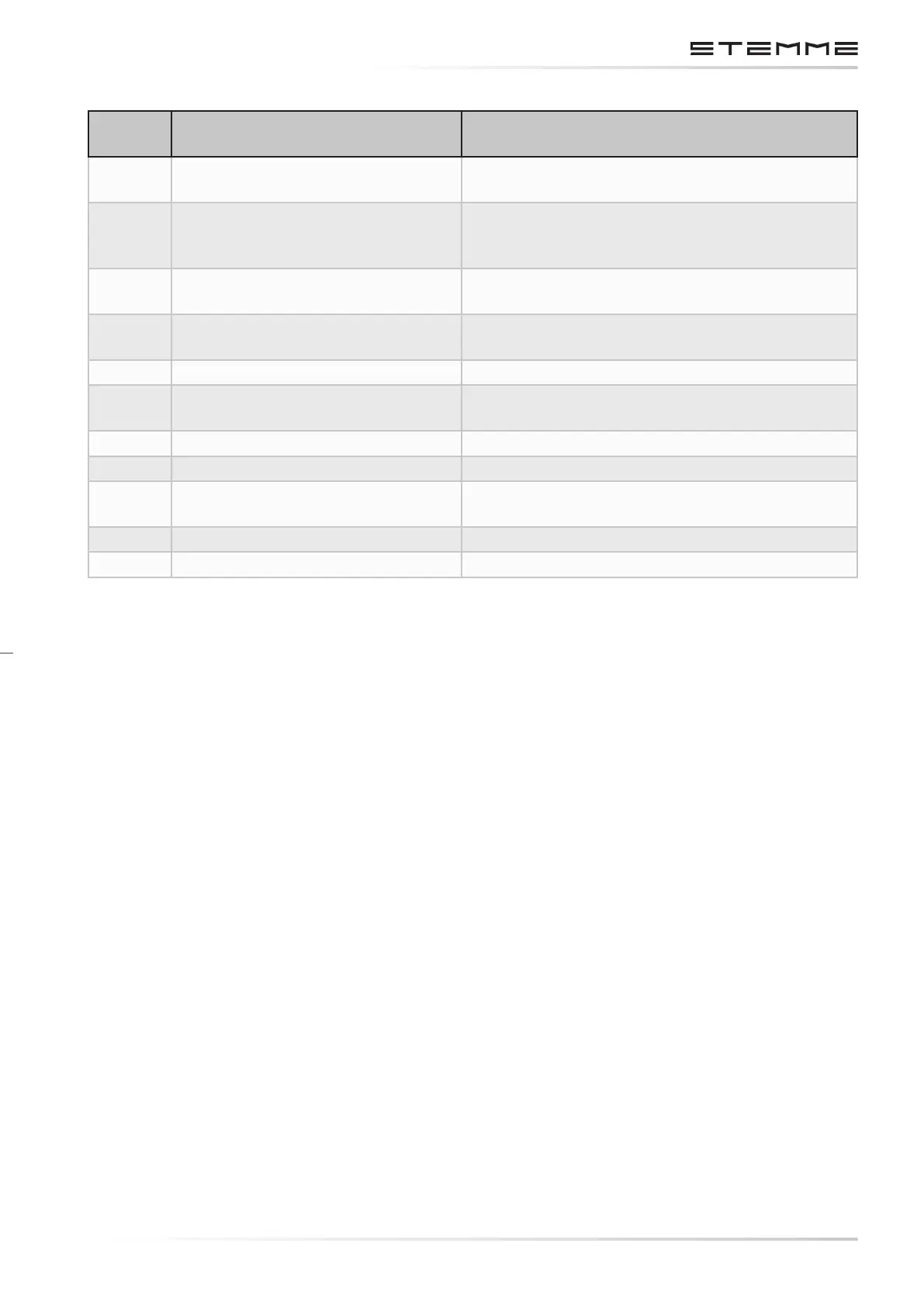

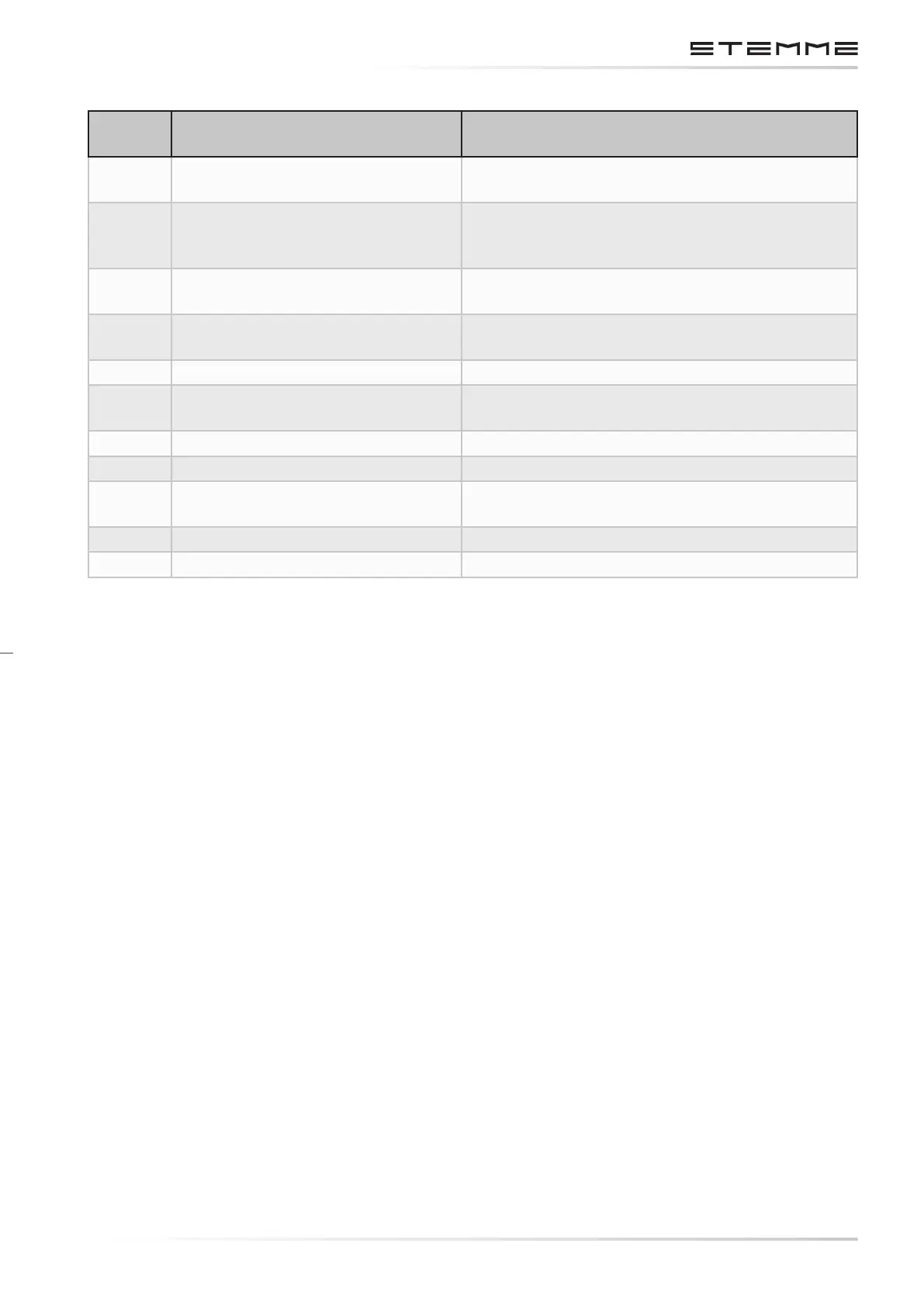

Position. Description Lubricant, Occasion and Remarks

(See also section 6.5.1)

(7) Forward and rear horizontal tail

tting.

Grease (any rigging and annually)

(8) L´Hotellier connection aileron

control rod.

Slightly grease only the ball (any rigging and

annually), see also manufacturer instruction

(Annex A)

(9) Spring parts of landing gear

doors.

Oil (any scheduled maintenance)

(10) Landing gear: Elbow strut, wheel

bearing, door hinges.

Grease (Inspection Type 2.c, door hinges annu-

ally)

(11) Hinge bolts of lower cowl ap. Grease, (Inspection annually)

(12) Control rods in fuselage, swivel

joints.

Grease, (every 2 years)

(13) Eye bolts of air brakes. Grease, (every 2 years)

(14) Flap control links. Grease, (every 2 years)

(15) Rudder hinges, control cable con-

nection.

Grease, (every 2 years)

(16) Tail wheel, lower axial guide. Grease, (every 2 years)

(17) Flap and elevator hinges Grease, only if corrosion has occurred

6.6 SURFACE OF COMPOSITE STRUCTURES

During any 100 hours airframe or higher inspection (100 or more engine hours or annually) the

total surface of the motorglider shall be inspected for damage or cracks. Look carefully for signs

of hidden structural damage during inspection. Bottom sides of fuselage, wings and elevator shall

be checked for gravel strike damage.

• Check all labels and repair or renew if necessary.

Additional remarks about identication of structural damage, especially in force transfer areas

etc. can be found in section 7.1 in relevant subsections for components.

According to the type approval data sheet the surface may only be colored white except

for registration and areas for warning colors. Warning colors can be used from winglets to

0.30 m / 11.81 in inboard, at the nose-cone and at the landing gear doors. For use of the white paint

observe the statements in the repair guide P520-901.502 Small Repairs of Composite Materials.

Loading...

Loading...