DOCUMENT NUMBER:

L500-912.820 ISSUE JUL 20, 2016

AMENDMENT: 00

DATE:

CHAPTERPAGE 71

MAINTENANCE MANUAL STEMME S12

7. MAINTENANCE INSTRUCTIONS, TOLERANCES AND ADJUSTMENT

DATA FOR ASSEMBLIES / EQUIPMENT

7.1 AIRFRAME

7.1.1 WING

Description: See section 3.1.1

Lubrication: See section 6.5

7.1.1.1 CRACKS AND STRUCTURAL DAMAGE

•

Check wings for cracks and abnormal surface (local buckles, roughness, holes and delami-

nation), especially near to force transmission points (ttings, control links, ap hinges) and

at the division areas of inner and outer wing as well as of outer wing and wing extension.

See also section 6.6 and Annex A Small Repairs of Composite Materials.

7.1.1.2 DRAINAGE AND VENTILATION HOLES

• Check holes for cleanness and for uid outow; clean if necessary. Fuel trails found may

indicate fuel tank leakage. The holes are located next to the air brakes, fuel tanks and next

to the wing root of inner and outer wing and wing extension (see position plan in section

6.7).

7.1.1.3 WING FITTINGS

•

Check backlash of the wing ttings by moving wing tips forward and aft and up and down.

If excessive backlash is found or in case of doubt the bolts and ttings must be measured

by means of a micro meter.

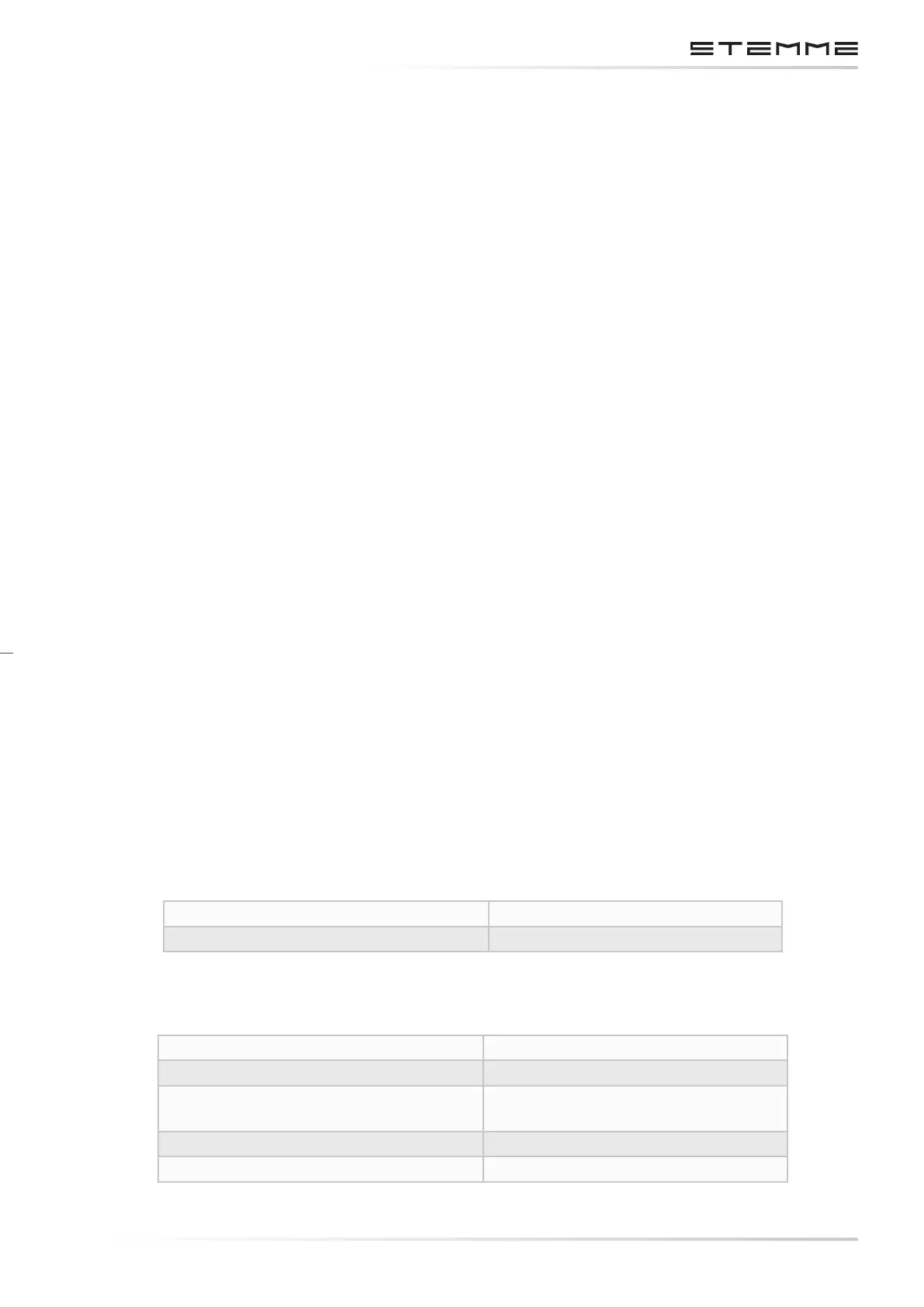

CLEARANCE OF WING/FUSELAGE ATTACHMENTS

Axial Maximum 0.4 mm / 0.016 in

Radial Maximum 0.15 mm / 0.006 in

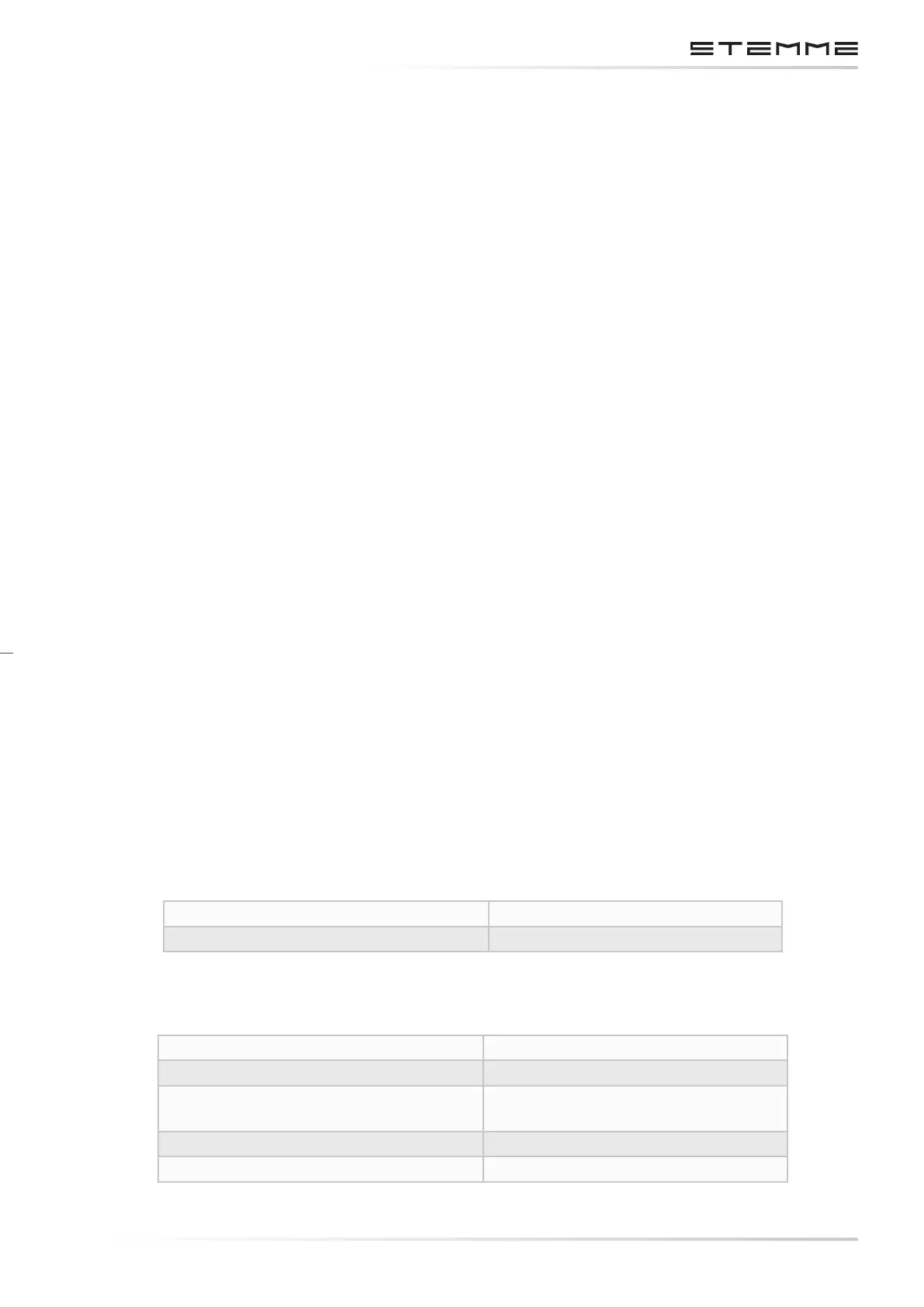

CLEARANCE OF INNERTOOUTER WING ATTACHMENTS

Front and rear bolts, axial Maximum 0.3 mm / 0.012 in each

Front and rear bolts, radial Maximum 0.2 mm / 0.008 in each

Main bolt, radial Maximum of 0.15 mm / 0.006 in

in the bearings of spar boxes.

Spar stub bolts axial Maximum 2 mm / 0.08 in

Spar stub bolts radial Maximum 0.2 mm / 0.008 in

Loading...

Loading...