DOCUMENT NUMBER:

L500-912.820 ISSUE JUL 20, 2016

AMENDMENT: 00

DATE:

CHAPTERPAGE 731

MAINTENANCE MANUAL STEMME S12

Balancing the variable pitch propeller or its assemblies may only be performed by the

manufacturer or by an authorized and licensed FBO according to the specic instructions and

using appropriate equipment.

Balancing weights have to be applied for static or dynamic balancing. Their arrangement must

be entered in the Rigging Report as laid down in the Propeller Rigging Report form (Annex D).

In the case of damage of one propeller blade only, a suitable exchange blade may possibly be

obtained from the manufacturer. The latest Report of Adjustment Settings must be transmitted

to the manufacturer and in this case, re-balancing may not be necessary.

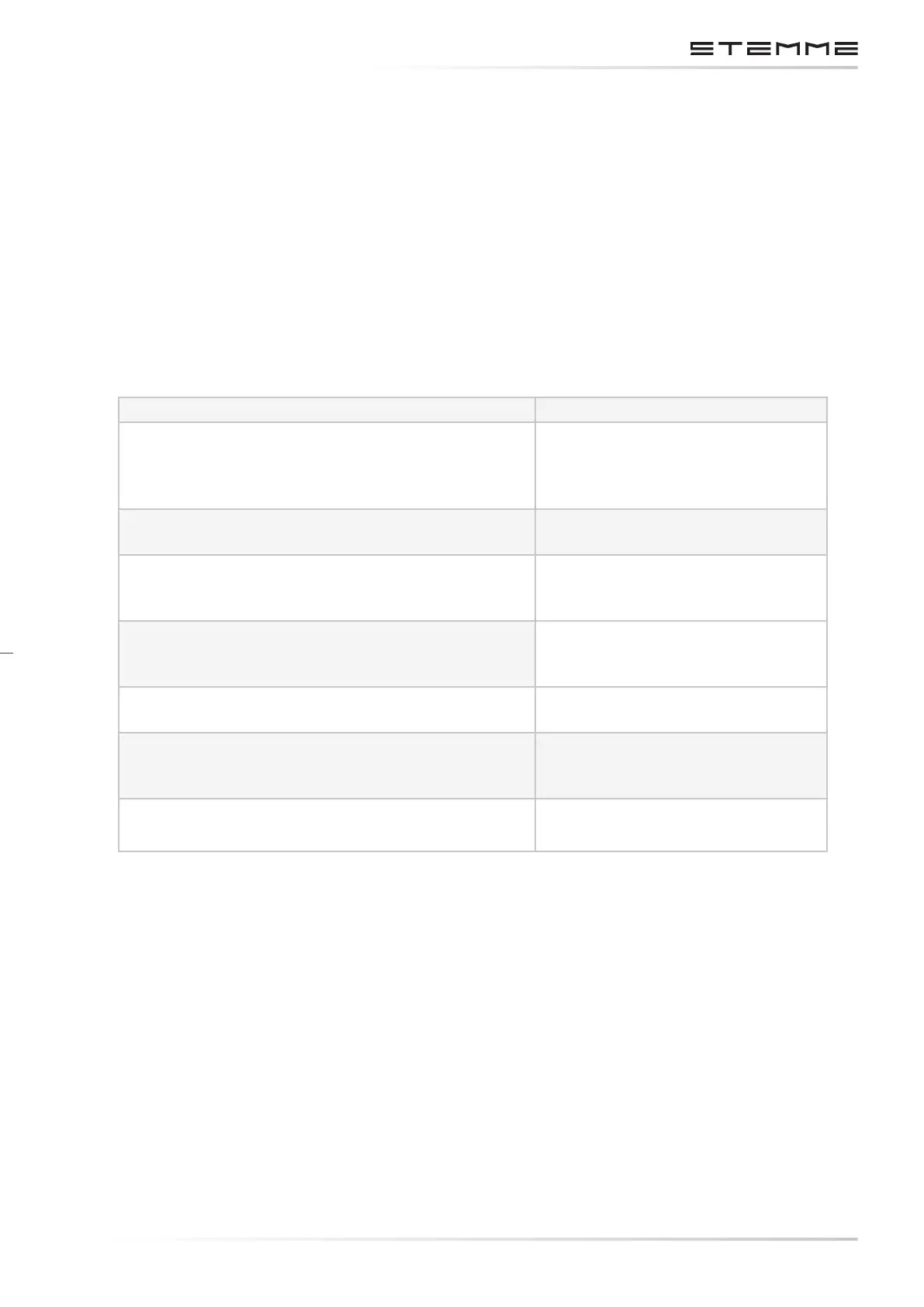

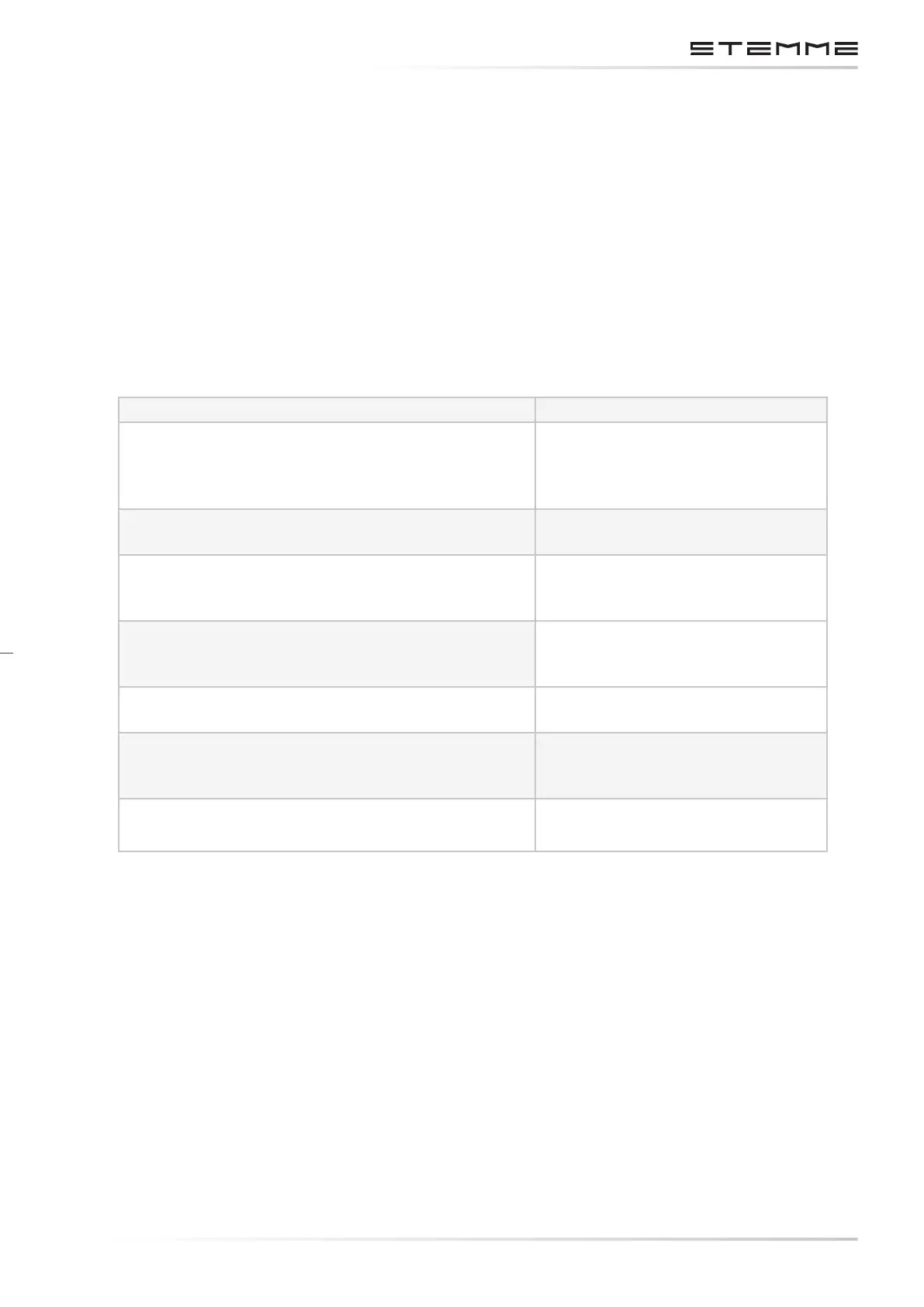

7.4.10.2 ADJUSTMENT AND INSPECTION RESULTS, TOLERANCES

Changes in pitch angle ß = 6° 24’ ± 15’

Settings, measurement taken at the propeller blade

mounting fork with reference to zero setting (this is

when the axis of the joint is parallel to the propeller

axis of rotation).

Take-O setting: -2° 30’± 5’

Cruise setting: +3° 54’± 10’

Initial tension of the contact spring for the take-o

position stop switch.

≈ 0.2 mm / 0.0079 in

(

1

/

3

turn of the contact screw)

Duration of pitch change in each direction at an ambient

temperature of 15° - 25° C and battery voltage of

not less than 12 V under loaded conditions.

max. 3 Min.

Unbalance: Permissible total static residual unbal-

ance.

Permissible dynamic unbalance.

200 g mm / 4.44 dr. in

see A17-10AP-V/2-E

Permissible travel of the blade tips in the direction

of ight.

4 mm / 0.16 in

Track at propeller blade joint (dierence between

both forks, measurement taken opposite the posi-

tion ‘upper left gear mount’).

0.3 mm / 0.12 in

Track at propeller blade tips (dierence between

both blades).

3 mm / 0.12 in

7.4.10.3 VISUAL INSPECTION OF THE PROPELLER UNIT

• Check load bearing elements (hub and forks, blade suspension) for cracks, corrosion and

other damage.

• Check complete propeller assembly for loose components, loose bolt connections or other

apparent damage.

• Check condition of rubber stops within the blades and on hub for cracks.

•

Check propeller blades for cracks or other damage, especially at blade tips, at bonding

seam and in the area of stop buers. Repair leading edge protection tape if necessary (use

material supplied by the manufacturer only!).

Loading...

Loading...