DOCUMENT NUMBER:

L500-912.820 ISSUE JUL 20, 2016

AMENDMENT: 00

DATE:

CHAPTERPAGE 76

MAINTENANCE MANUAL STEMME S12

7.1.3.3 HORIZONTAL TAIL

• Check forward tting for cracks and corrosion, tight t of screw connection, smooth op-

eration of spring bolt (observe section 6.5 Lubrication), backlash of bolt and sucient

spring tension for safe locking.

• Check rearward tting for cracks, especially in or close to welding seams and the cut-outs

of the xing plates, tight t of screw connection and wear of pins.

• Check nut of the assembly screw stop.

• Check backlash of the horizontal tail tting (do not apply excessive force):

- Move horizontal tail tip forward and aft and up and down.

- Take hold of the mid section of the horizontal tail n, push up and down.

If excessive backlash is found, the bolts and ttings must be measured.

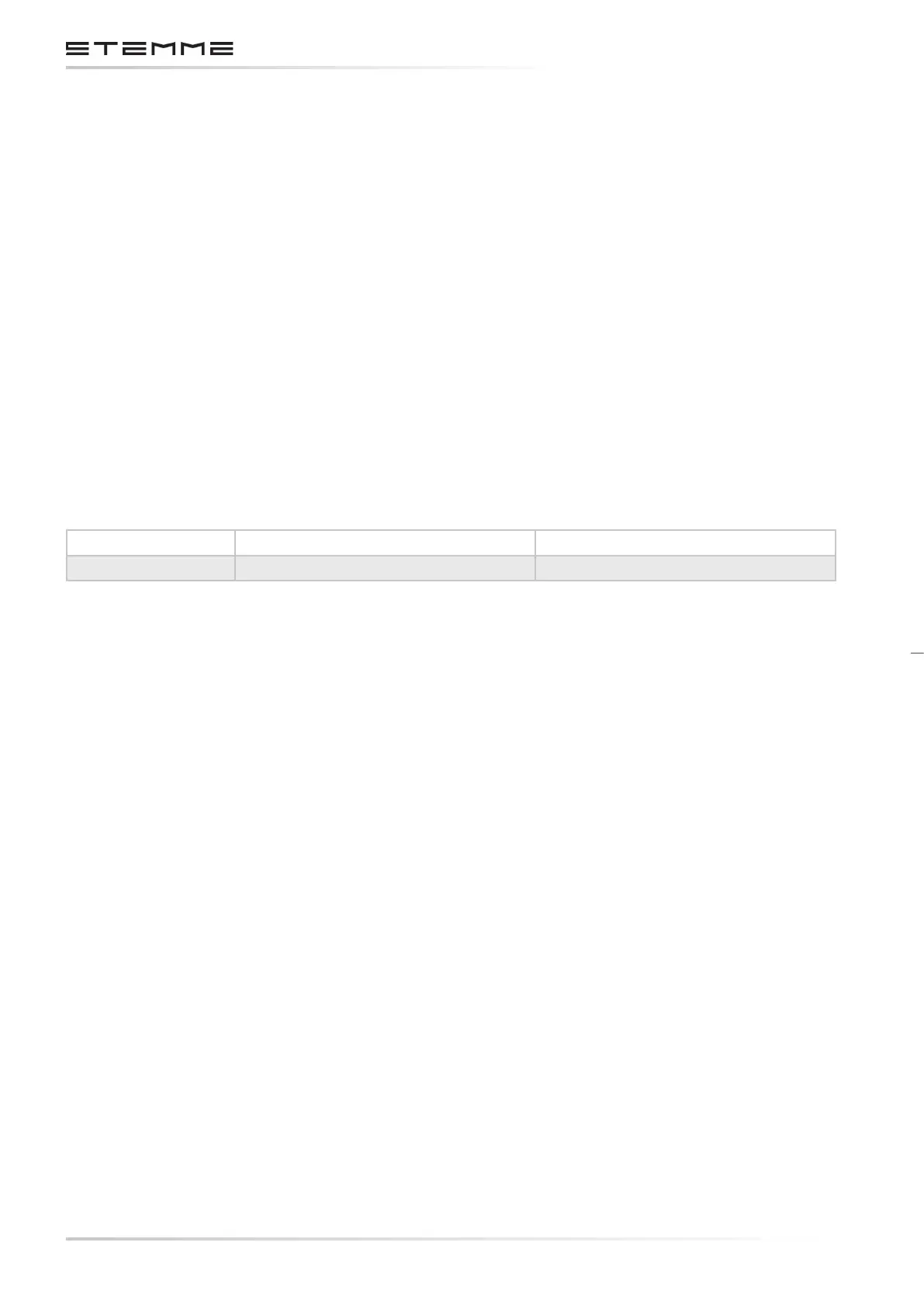

MAXIMUM BACKLASH OF HORIZONTAL TAIL FITTINGS

Forward tting Vertically 0.15 mm / 0.006 in Horizontally 0.1 mm / 0.004 in

Rear tting Vertically 0.15 mm / 0.006 in Horizontally 0.15 mm / 0.006 in

7.1.3.4 WEIGHTS AND STATIC HINGE MOMENTS OF CONTROL SURFACES

Upon repair and re-painting the control surfaces weights and static hinge moments must be

measured. If the limits are exceeded, contact the manufacturer.

Weights and Hinge Moments: See section 6.4.2

Deections: See section 6.4.1

Loading...

Loading...