DOCUMENT NUMBER:

L500-912.820 ISSUE JUL 20, 2016

AMENDMENT: 00

DATE:

CHAPTERPAGE 616

MAINTENANCE MANUAL STEMME S12

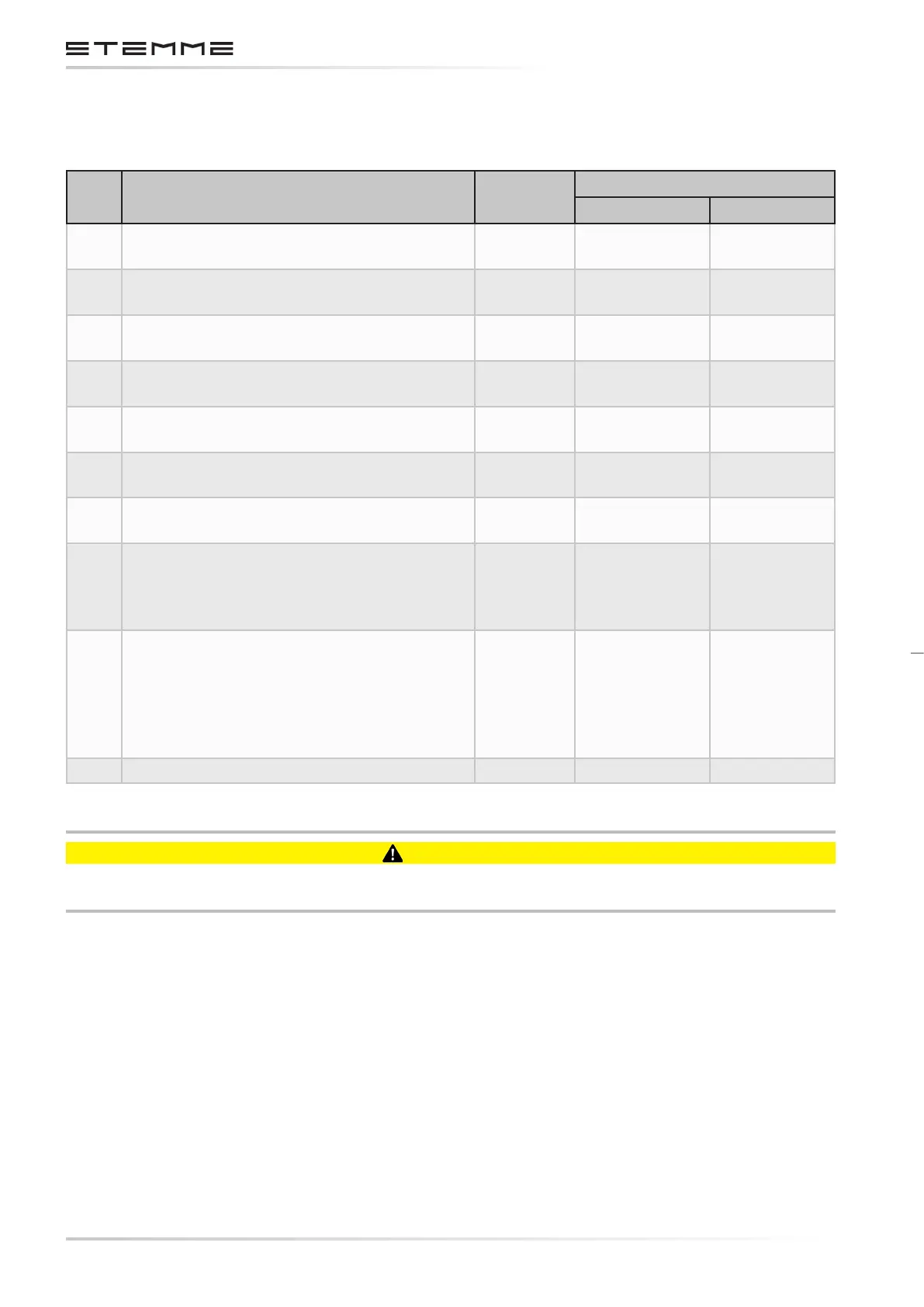

NONSTANDARD TIGHTENING TORQUES INCLUDE THE FOLLOWING FOR EXAMPLE

Item Designation Loctite Tightening Torque

[Nm] [lbf ft]

1. M8 connecting clutch and propeller

ange of the engine.

without 22 16

2. M10 connecting clutch and exible disk

(drive shaft).

243 35 25.8

3. M10 connecting exible disk and forked

sleeve of the drive shaft.

243 35 25.8

4. M10 connecting drive shaft and exible

disk (front gear).

243 35 25.8

5. M10 connecting exible disk and front

gear.

221 35 25.8

6. M8 connecting front gear in the gear sus-

pension.

without 16 11.8

7. M8 fastening screws of the propeller hub

on the front gear ange.

without 1st step: 10

2nd step: 30

1st step: 7.4

2nd step: 22.1

8. M8 locking nut on the propeller fork.

WARNING

- not included in normal maintenance

without 20 14.7

9. Yield bolt fastening the fork on the pro-

peller hub.

WARNING

- screw thread lubricated.

- not included in normal maintenance

without 1st step: 50

2nd step: 16

1st step: 36.9

2nd step: 11.8

10. Magnetic screw in the front gear. without 15 - 20 11.1 – 14.7

CAUTION

Screws and bolts secured by Loctite 243!

ENGINE

For tightening torques of screw connections on the engine refer to Maintenance Manual (Line

Maintenance) for ROTAX Engine Type 914 Series (Annex E), Maintenance Manual (Heavy

Maintenance) for ROTAX Engine Types ROTAX 912 and 914 Series and applicable SI, SB and SL.

Loading...

Loading...