OPERATION & MAINTENANCE MANUAL SWE155F

4.5.3.3 Checking and Fastening Track Bolts

If operating machine with bolts loosened, there is hazard

that the bolts will rupture. Therefore the loosened bolts

should be fastened.

Tightening Method

Track shoe

1) Tighten at torque 490 ± 49 N m (50 ± 5 kgf m, 360 ±

36 lbft), then check to make sure that nuts contact

with track link surfaces securely.

2) After checking, retighten 120° ± 10°.

Rubber block ( if mounted)

1) Tighten at torque: 549 ± 59 N m (56 ± 6 kgf m, 405 ±

43 lbft).

2) After tightening, check to ensure that nut and track

link contact surface contact against each other

securely. .

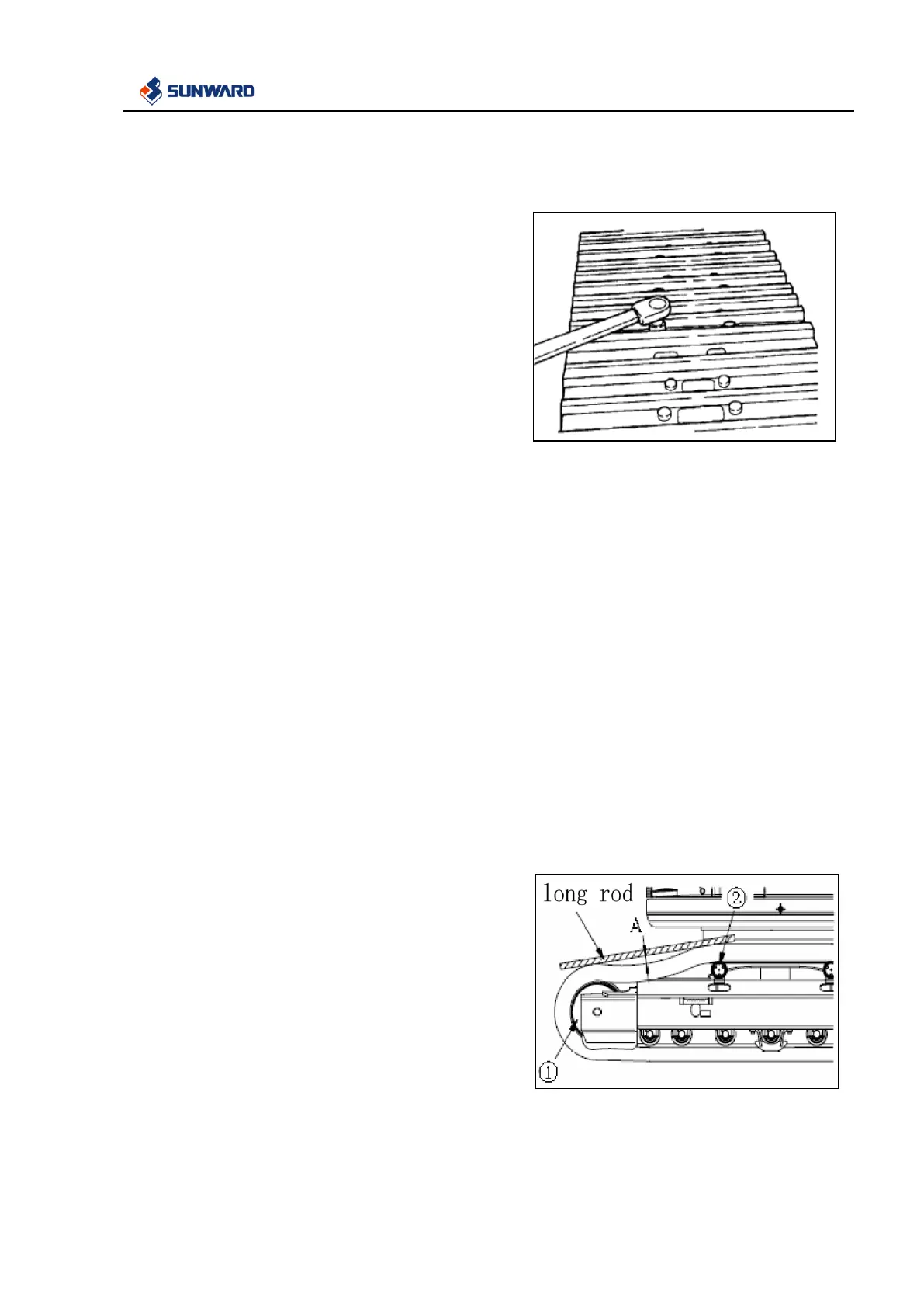

Tighten Sequence

Tighten bolts in the sequence given in right fig.

With bolts tightened, check bolts and track link mating

face to ensure they contact securely.

4.5.3.4 Checking Track Tension

Run engine at low idling, move the machine forward

a distance equals to the length of track on ground.

Then stop the machine.

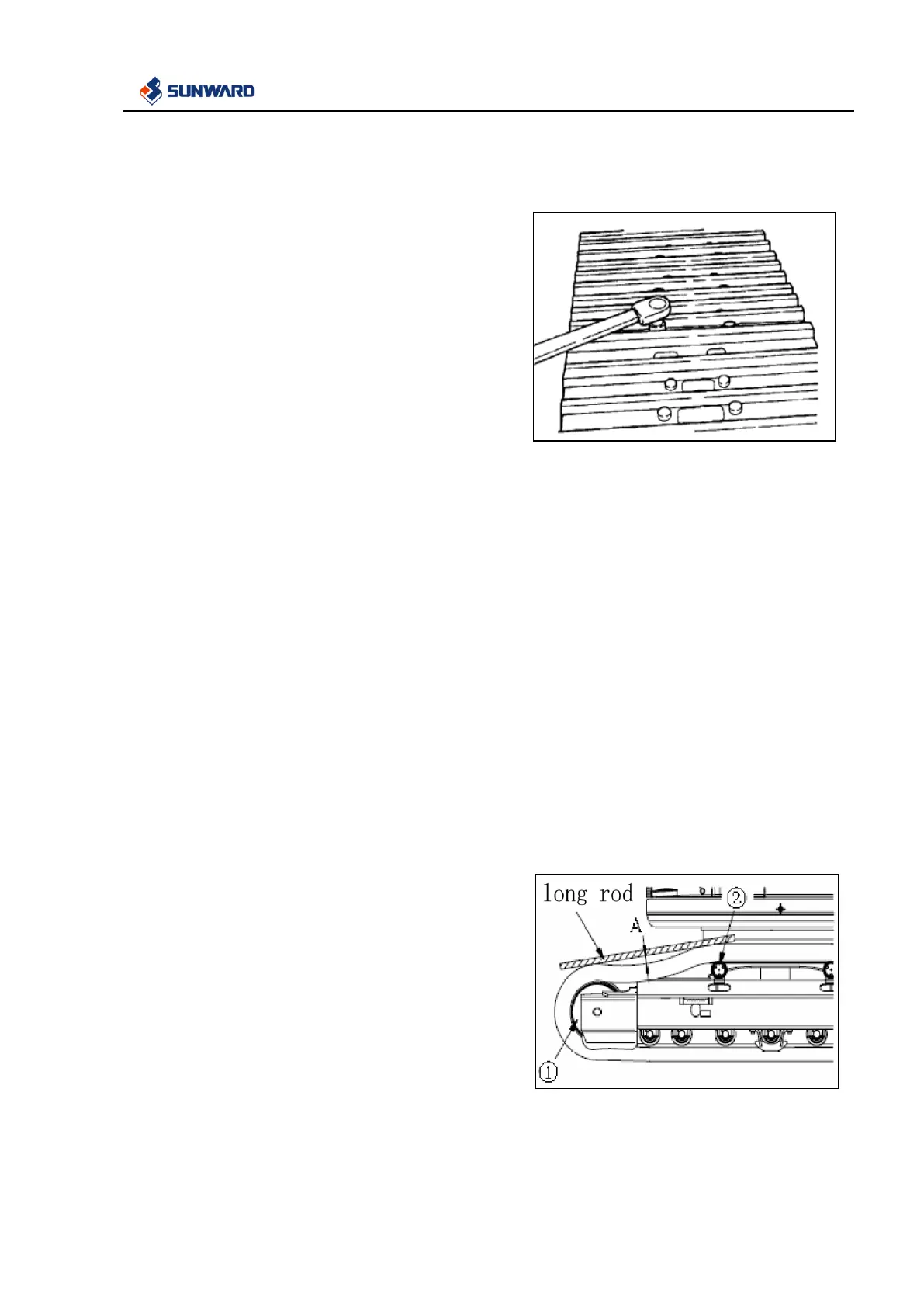

As shown in right fig, choose a straight long rod;

place it on track over idler ① and carrier roller ②,

measure the max distance “A” between upper surface

of track and bottom surface of the rod.

Standard deflection “A” should be 20-28 mm

(0.8-1.1 in).

If the track tension is not at standard value, adjust it in

the following manner:

1) Pump in grease through grease fitting② with a

grease pump.(pump fitting② and plug screw ①

Loading...

Loading...