OPERATION & MAINTENANCE MANUAL SWE155F

4.5.7 Every 500 Hours Maintenance

When the machine works for every 500 hours, take the

maintenance as specified in this chapter and carry out

maintenance of every 50 hours, every 100 hours and 250

hours at the same time.

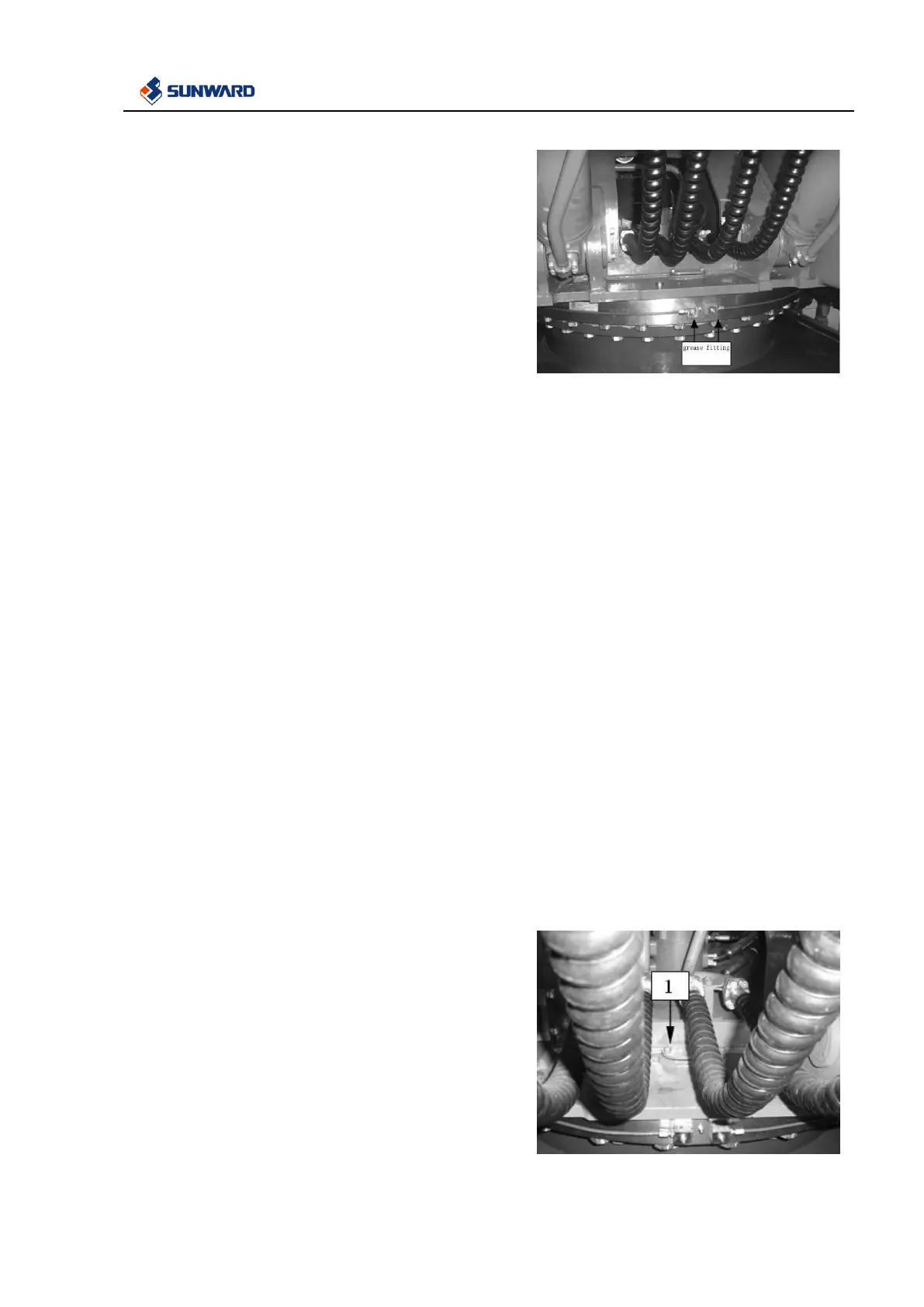

4.5.7.1 Greasing Ball Track of Swing Bearing

Stop the machine at level ground, lower the bucket at

level ground.

Shut auto-idle speed switch, run the engine unloaded

at low speed for 5 minutes.

【Important】

Stopping the engine improperly may damage

turbocharger.

Set start key to OFF position, stop the engine, remove

the key from starting lock, set pilot safety lever to

LOCK position.

Pump in grease through 3 grease fittings to swing

bearing ball track.

Start engine, lift bucket, and swing upper-structure at

45°.

Repeat 3 times from step 3 until lubricating grease

overflows from swing bearing seal.

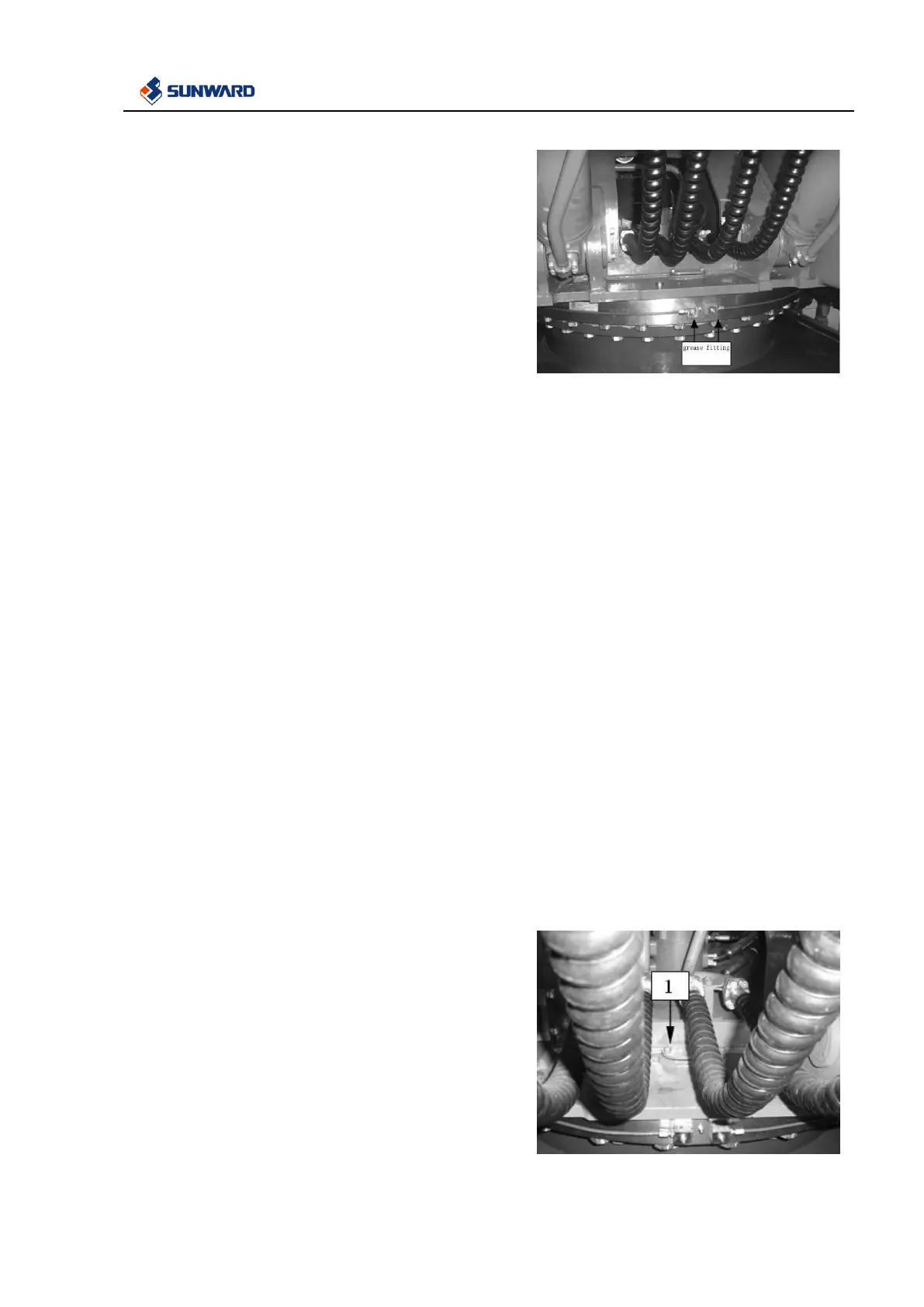

4.5.7.2 Lubricating Swing Mechanism

Stop the machine at level ground, lower the bucket to

ground.

Stop auto-idle switch, run the engine unloaded at low

speed for 5 minutes.

【Important】

Stopping the engine improperly may damage

turbocharger.

Set start key to OFF position, stop the engine, remove

the key from starting lock, set pilot safety lever to

LOCK position.

Loosen 2 bolts of grease fill port cover located on

front part of platform. Then remove grease fill port

cover (1).

Check that grease height in the position where pinion

passes by should be at least 14mm (0.6in), and free of

Loading...

Loading...