OPERATION & MAINTENANCE MANUAL SWE155F

1.4.10 Maintenance Precaution of Track Tension Mechanism

Grease is being pumped into track tension adjustment

system under high pressure. During adjustment

operation, if the specified maintenance procedures are

not followed, the lubricating grease drain plug (1) may

fly out leading to serious injury and damage.

When loosening grease drain plug (1) to loosen the

track tension. Never loosen it more than one turn.

Loosen the grease drain plug slowly.

Never put your face, hands, feet, or any other part of

your body close to grease drain plug (1).

Recoil spring assembly contains a compression spring

which serves as a shock absorber for the idler. If it is

disassembled improperly, spring may fly out and cause

serious injury and even death. Do not disassembly

recoil springs.

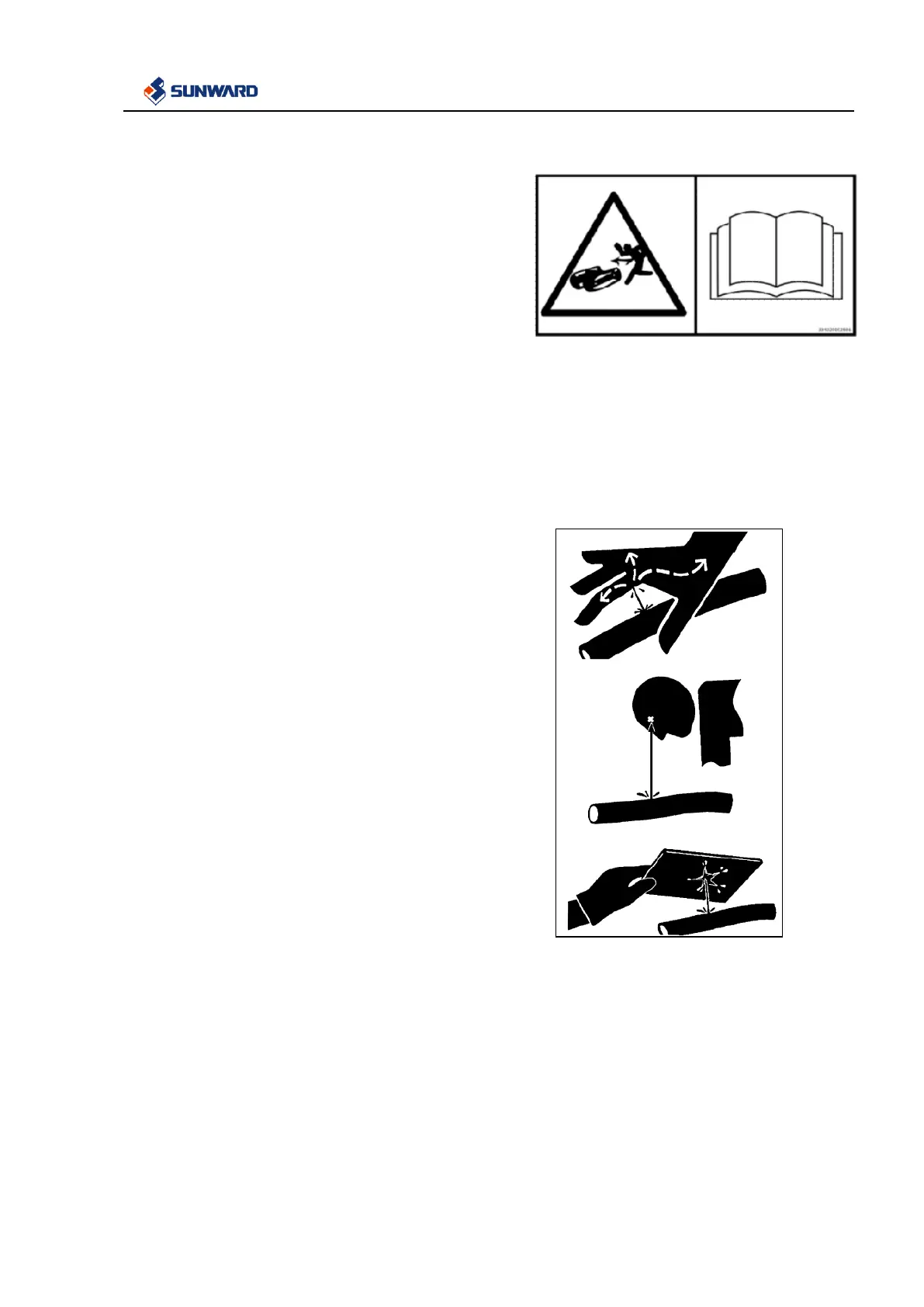

1.4.11 Safety Rules for High-pressure Oil

Hydraulic system is always under internal pressure.

When inspecting or replacing piping or hoses, always

check that the pressure in the hydraulic circuit has

been released. If the circuit is still under pressure, it

will lead to serious injury, so always do as follow.

Never attempt any inspection or replacing operation

if hydraulic system is under pressure.

If there is any leakage from piping or hoses, the

surrounding area is wet, so check for cracks or

swelling in the hoses. When carrying out inspection,

wear goggles and leather gloves.

High pressure oil leaking from small holes may

penetrate your skin or cause blindness if it contacts

your eyes. If you are hit by a jet or high pressure oil

and suffer injury to your skin or eyes, wash the place

with clean water, and consult a doctor immediately

for medical attention.

Loading...

Loading...